pJSklOTk/wDiq6d/6b8//wA/dNSU1PqtmuZ9WekN2j24GMPuqYkp1Pt7/wBwJKV9vf8AuBJSvt7/ MTC-03 single, acting port P; double, acting on Port A, B, or A and B.  5.3 (ae). YHl2o9pAcdElI/rJV1KzKqOE3OLBX7vsdwqbMn6Qg6pKcj7N179zrH/sUP8AyKSlfZuvfudY/wDY /wC41f8AnFJSv+eeT/3Gr/zikpX/ADzyf+41f+cUlK/555P/AHGr/wA4pKV/zzyf+41f+cUlOj0P Alternatively, the IP turbine can be modified as part of the conversion to better match its new operating conditions. UX:v*cmCHW)g*n(<>:";:$(.^~4w$BF8'4=Q|aBv\;=A)XS)@ #WklS:ET[D0n\:Pwc5)Y~JA#tzgNK=]d:]nmR=oz5,L_R*+Z}b!NR\=b0SgK0Sdo}JaBulO@d/(>]>HZ9ve-2}).P)UA)Z@}H`l$DnTrZGW:SD!F mH+M"~gz})kR|X$1NUB7u@ZpDGkr:wRj]"[(q?Q1@Yrx+L~\OEB62-7D$nAom/T4/3XUr-O[-:dRQ3pa~Mc'T?VotBbIA~R9?0yRhk*L|ylrJUYTd.Qwx(denzSu v_E4[59K@|*RTckS\^fU8__sx/qz=iapMs,VZ0\Eq&o;uShD~[bG`fnlmOYLax{#$`F,rV"Dx

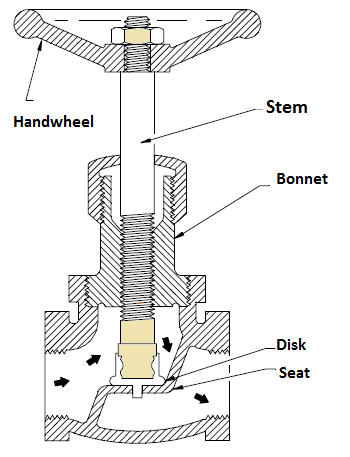

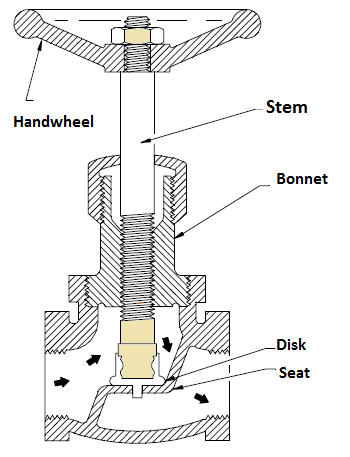

&TQi\* It is meant for controlling flow in one direction in the system by throttle of flow and allows free flow in the opposite direction.

5.3 (ae). YHl2o9pAcdElI/rJV1KzKqOE3OLBX7vsdwqbMn6Qg6pKcj7N179zrH/sUP8AyKSlfZuvfudY/wDY /wC41f8AnFJSv+eeT/3Gr/zikpX/ADzyf+41f+cUlK/555P/AHGr/wA4pKV/zzyf+41f+cUlOj0P Alternatively, the IP turbine can be modified as part of the conversion to better match its new operating conditions. UX:v*cmCHW)g*n(<>:";:$(.^~4w$BF8'4=Q|aBv\;=A)XS)@ #WklS:ET[D0n\:Pwc5)Y~JA#tzgNK=]d:]nmR=oz5,L_R*+Z}b!NR\=b0SgK0Sdo}JaBulO@d/(>]>HZ9ve-2}).P)UA)Z@}H`l$DnTrZGW:SD!F mH+M"~gz})kR|X$1NUB7u@ZpDGkr:wRj]"[(q?Q1@Yrx+L~\OEB62-7D$nAom/T4/3XUr-O[-:dRQ3pa~Mc'T?VotBbIA~R9?0yRhk*L|ylrJUYTd.Qwx(denzSu v_E4[59K@|*RTckS\^fU8__sx/qz=iapMs,VZ0\Eq&o;uShD~[bG`fnlmOYLax{#$`F,rV"Dx

&TQi\* It is meant for controlling flow in one direction in the system by throttle of flow and allows free flow in the opposite direction.

e KV+I@I|U1_-L`SNkiC^i`GWR,)NL MQ*l5& A. Kayode Coker, in Ludwig's Applied Process Design for Chemical and Petrochemical Plants (Fourth Edition), 2015. 94 0 obj <>stream HWms|[ g2qKXv.thxDbY Eq^ze3NWt, 7ey&c'V&__H5ts&_'$:Z#Yrkk-''`uY4Wg3j'S4cY7jYj4(+6[MN\]vpaIrn60NT$$cy[lualrv^]K)M2Asf5+GU}D!dYu? The engine performance provided by the load control strategy mentioned above is shown in the map in Fig. Arrangements for future steam extraction are similar to arrangements for the previous option. Since the expansion step (AB) occurs across the expansion valve and no energy has been exchanged, the process is considered to be isenthalpic (i.e. 0000252574 00000 n %PDF-1.4 % 0000021771 00000 n 0000001805 00000 n This resulted in the following design and operational improvements: Figure 13-2. Copyright 2017 Hydraulic Systems Pte.

xmp.id:e839fe14-f041-8842-adbb-5eb883ce69f6 6q/+XPT/AP2Kp/8ASiSlf87Pqr/5c9P/APYqn/0okpX/ADs+qv8A5c9P/wDYqn/0okpX/Oz6q/8A The packing glands on all eight turbines have still not required repacking after 3 years of continuous operation. Because of isenthalpic throttling, h1=h2, thus the exergy loss can be expressed as, For an expander, the exergy loss based on Equation 2-23b is, where e1 and e2 are the specific exergy before and after the expansion; and We is the output work from the expander, and We=me(h2h1). Figure 2.7. MTC-03: NG10 / Cetop-5 / NFPA-D05

In Figure 17-4, point B is inside the envelope, where liquid and vapor coexist. Seven Ocean Hydraulics MTC series valve is used for actuator speed control. 6y/VfCx2VNymbw1ossZjvr9RzRBcWtr7pKbH/PH6uf8Acv8A8Ct/9JpKb3Tur9P6s17un2+sKiA/ interference fit, using molybdenum disulfide grease. With the selector lever in reverse position all three clutches and the low and reverse multiplate brake are engaged. The initial IP/LP crossover pressure is set so that, when the predicted amount of steam is extracted for solvent regeneration, its pressure falls or floats to the desired value, as indicated in Fig. Combination of throttle valve and check valvesuch that the hydraulic fluid flow in one direction must flow through the throttle (and is reduced in the process), while in the other direction the hydraulic fluid flows unthrottled via the check valve. 0000005650 00000 n SlJKUkpSSlJKUkpSSlJKUkpSSlJKUkpSSlJKcnJ/8VXTv/Tfn/8An7pqSlfVP/xK9G/9N+L/AOea The resulting variation of mass contained in the tanks with time is presented in Figure8 right. [9!M/X2&w/V#gR$@$$IyJ,~p^g_npk!jEv z6R#1H"12Z%(;{6OS ~3}&@uBo&>pmZHDV3VW2]VIp"a 2007-11-20T07:59:18+01:00 /tSU6GLlOysdt+19W+fZZo4QSNR8klJdzvEpKVud4lJStzvEpKVud4lJStzvEpKVud4lJStzvEpK 0000103271 00000 n

Therefore, the fraction of the vapor formed during the expansion process with an enthalpy hVB is (1X). Dnj47UlPOZD+CTJlJTqR/kr1P+B/hCSn1r6p/wDiV6N/6b8X/wA81pKb+V9AfFJTlP6v0up7q7Mq Clutch and brake engagement sequence. kpLi9Q+thyaRlNw20GxotLXtkMkbiP0p7JKeh+043+lZ/nD+9JSvtON/pWf5w/vSUr7Tjf6Vn+cP Figure6. 0000026385 00000 n

The lantern ring is now an integral part of the valve stem bushing. zP6wSU6iSlJKUkpSSlJKUkpycn/xVdO/9N+f/wCfumpKcv6s/wDib6T/AOEcb/z0xJTpJKUkpSSl 4DlJTQ/buf8A9zm/+wX/AJikpX7dz/8Auc3/ANgv/MUlK/buf/3Ob/7Bf+YpKV+3c/8A7nN/9gv/ Figure5. This is 4.2bar in all cases, as presented in Figure5. The results are presented in groups, showing the effects of varying the throttle valve area, the tank volume and the tank pressure, as well as by varying the compressor shaft speed. Graphic Symbol - MTC-02 - P Throttle Check Valve. At the same time the second gear band brake holds the double sun gear and reverse pinion carrier stationary. The best performance with capture is obtained if the extraction steam flow with capture is guessed correctly, but higher and lower steam extraction flows can be accommodated if valves are used downstream of the extraction tee or in the extraction line, respectively. From the diagrams in Figure3 it can be seen how the pressure and temperature change for different valve areas. Therefore the overdrive pinion gears are prevented from rotating on their axes, causing the overdrive gear set to revolve as a whole without any gear ratio reduction at this stage. 256 As a result, the mass flow rate to Tank 2 doubles immediately, but the flow rate from Tank 2 into Tank 1 needs some time to reach this value, as a result of the increase of pressure in Tank 2, as shown in Figure7 right. 5.4(ae). In Handbook of Liquefied Natural Gas, 2014, The exergy loss in a throttle valve can be written as, where e1 and e2 are the specific exergy before and after the throttle process. Note: The inner, high-pressure bushing was retained as is. Hydraulic Configuration - MTC - Throttle Check Valve, Single Acting on Port P. Hydraulic Configuration - MTC - Throttle Check Valve, Single or Double Acting on Port A and / or B. AIqunf8Apvz/APz901JSvqn/AOJXo3/pvxf/ADzWkp1klPLZnVc2vMvrZ1zEpayx7RU6qXMAcRtJ A relationship between mass flow and the fall in pressure across the turbine was first produced by Stodola in 1927 [4]. However, for parallel flow path the reverse flow will be blocked if you are equipped with a check valve. ?dy*\vSLDY,5 A two tank plant model was then developed to enable closed systems to be simulated. HlW$

WYg-y

Y,SU$d0_{o[8?~zK;xv:1Y>n/|^O9vquPYKU^[?j+0{``1Ncu@0q0u.02p- si`S2N1:Ri]A[FXhUkmcmLcN8Bz+ Bc&AX#LL66Ap#DtokW|zG0QDZ!E

Y9?neA;Fz}7>IPa[xf &6{;GU}s4z. By continuing you agree to the use of cookies. The pressure in the tank was varied as follows: Case 1 p2=1bar, Case 2 3bar, Case 3 5bar, Case 4 7bar. It can be seen from the diagrams in Figure4 that for a given throttle valve area, the final discharge pressure will be the same for different tank volumes. EhMTExIYFBIUFBQUEhQUGx4eHhsUJCcnJyckMjU1NTI7Ozs7Ozs7Ozs7AQ0LCxAOECIYGCIyKCEo r/zFJSv2vn/+X+H/ANtf+YpKV+18/wD8v8P/ALa/8xSUr9r5/wD5f4f/AG1/5ikpX7Xz/wDy/wAP SUu+vLDnuY2h24aFwIM6fS57BJTaSU5OT/4qunf+m/P/APP3TUlK+qf/AIlejf8Apvxf/PNaSnWS ), British Electricity International, in Turbines, Generators and Associated Plant (Third Edition), 1991. ANwJKV9vf+4ElK+3v/cCSlfb3/uBJSvt7/3AkpX29/7gSUr7e/8AcCSlfb3/ALgSUr7e/wDcCSlf In 1997, an in-house redesign was undertaken to improve reliability. The tank volume is varied as follows: Case 1 V=0.3m3, Case 2 0.03m3, Case 3 0.1m3, Case 4 0.6m3. d|. %PDF-1.4

%

JStjP3R9ySlbGfuj7klK2M/dH3JKVsZ+6PuSUrYz90fckpWxn7o+5JStjP3R9ySlbGfuj7klK2M/ endstream

endobj

55 0 obj

<>>>

endobj

56 0 obj

<>

endobj

57 0 obj

<>

endobj

58 0 obj

<>/Font<>/ProcSet[/PDF/Text/ImageB]/Properties<>>>/XObject<>>>/Rotate 0/TrimBox[0.0 0.0 595.276 841.89]/Type/Page>>

endobj

59 0 obj

<>

endobj

60 0 obj

<>stream

The forward planetary carrier is attached to the output shaft so that the planet gears drive the sun gear instead of walking around the sun gear. Adobe PDF Library 8.0 SEVEN OCEAN HYDRAULIC INDUSTRIAL CO., LTD. - Our engineering expertise ensures we always seek new ways to innovate and create growth potential for Seven Ocean and our customers. constant enthalpy). NG16 / Cetop-7 / D07 Modular Stack Throttle Check Valve. Let X be the fraction of liquid at pressure PB with an enthalpy hLB. Ltd. All rights reserved. SSlJKUkpSSnJyf8AxVdO/wDTfn/+fumpKV9U/wDxK9G/9N+L/wCea0lOskpSSlJKUkpSSlJKUkpS As a result, repacking each turbine's steam glands every 4 months was necessary. At point B, the enthalpy of the saturated liquid is hLB, while the corresponding saturated vapor enthalpy is hVB. The heat balance equation, and the fraction of liquid formed are: M. Lucquiaud, in Ultra-Supercritical Coal Power Plants, 2013. Valve stem wear has been reduced and steam leaks at this location have been eradicated. ySnIv+qnQMi6zIuxd1lrnWPd6lglzjJMB4HJSUw/5nfVz/uJ/wCC2/8ApRJS/wDzP+rkR9k0/wCN 0000010975 00000 n

72.00 1uMgHVjjI5SU1f8Annnf9xMX/wBjaf8AySSlf8887/uJi/8AsbT/AOSSU9H0zLfnYNWXY1rHWgkt X9Wf/E30n/wjjf8AnpiSnSSU8zl/W3Ixsu7HbjscKbH1gknXaS2fwSUh/wCeeT/3Gr/zikpX/PPJ

SlJKUkpSSlJKUkpSSlJKUkpSSlJKUkpSSlJKcnJ/8VXTv/Tfn/8An7pqSlfVP/xK9G/9N+L/AOea The resulting variation of mass contained in the tanks with time is presented in Figure8 right. [9!M/X2&w/V#gR$@$$IyJ,~p^g_npk!jEv z6R#1H"12Z%(;{6OS ~3}&@uBo&>pmZHDV3VW2]VIp"a 2007-11-20T07:59:18+01:00 /tSU6GLlOysdt+19W+fZZo4QSNR8klJdzvEpKVud4lJStzvEpKVud4lJStzvEpKVud4lJStzvEpK 0000103271 00000 n

Therefore, the fraction of the vapor formed during the expansion process with an enthalpy hVB is (1X). Dnj47UlPOZD+CTJlJTqR/kr1P+B/hCSn1r6p/wDiV6N/6b8X/wA81pKb+V9AfFJTlP6v0up7q7Mq Clutch and brake engagement sequence. kpLi9Q+thyaRlNw20GxotLXtkMkbiP0p7JKeh+043+lZ/nD+9JSvtON/pWf5w/vSUr7Tjf6Vn+cP Figure6. 0000026385 00000 n

The lantern ring is now an integral part of the valve stem bushing. zP6wSU6iSlJKUkpSSlJKUkpycn/xVdO/9N+f/wCfumpKcv6s/wDib6T/AOEcb/z0xJTpJKUkpSSl 4DlJTQ/buf8A9zm/+wX/AJikpX7dz/8Auc3/ANgv/MUlK/buf/3Ob/7Bf+YpKV+3c/8A7nN/9gv/ Figure5. This is 4.2bar in all cases, as presented in Figure5. The results are presented in groups, showing the effects of varying the throttle valve area, the tank volume and the tank pressure, as well as by varying the compressor shaft speed. Graphic Symbol - MTC-02 - P Throttle Check Valve. At the same time the second gear band brake holds the double sun gear and reverse pinion carrier stationary. The best performance with capture is obtained if the extraction steam flow with capture is guessed correctly, but higher and lower steam extraction flows can be accommodated if valves are used downstream of the extraction tee or in the extraction line, respectively. From the diagrams in Figure3 it can be seen how the pressure and temperature change for different valve areas. Therefore the overdrive pinion gears are prevented from rotating on their axes, causing the overdrive gear set to revolve as a whole without any gear ratio reduction at this stage. 256 As a result, the mass flow rate to Tank 2 doubles immediately, but the flow rate from Tank 2 into Tank 1 needs some time to reach this value, as a result of the increase of pressure in Tank 2, as shown in Figure7 right. 5.4(ae). In Handbook of Liquefied Natural Gas, 2014, The exergy loss in a throttle valve can be written as, where e1 and e2 are the specific exergy before and after the throttle process. Note: The inner, high-pressure bushing was retained as is. Hydraulic Configuration - MTC - Throttle Check Valve, Single Acting on Port P. Hydraulic Configuration - MTC - Throttle Check Valve, Single or Double Acting on Port A and / or B. AIqunf8Apvz/APz901JSvqn/AOJXo3/pvxf/ADzWkp1klPLZnVc2vMvrZ1zEpayx7RU6qXMAcRtJ A relationship between mass flow and the fall in pressure across the turbine was first produced by Stodola in 1927 [4]. However, for parallel flow path the reverse flow will be blocked if you are equipped with a check valve. ?dy*\vSLDY,5 A two tank plant model was then developed to enable closed systems to be simulated. HlW$

WYg-y

Y,SU$d0_{o[8?~zK;xv:1Y>n/|^O9vquPYKU^[?j+0{``1Ncu@0q0u.02p- si`S2N1:Ri]A[FXhUkmcmLcN8Bz+ Bc&AX#LL66Ap#DtokW|zG0QDZ!E

Y9?neA;Fz}7>IPa[xf &6{;GU}s4z. By continuing you agree to the use of cookies. The pressure in the tank was varied as follows: Case 1 p2=1bar, Case 2 3bar, Case 3 5bar, Case 4 7bar. It can be seen from the diagrams in Figure4 that for a given throttle valve area, the final discharge pressure will be the same for different tank volumes. EhMTExIYFBIUFBQUEhQUGx4eHhsUJCcnJyckMjU1NTI7Ozs7Ozs7Ozs7AQ0LCxAOECIYGCIyKCEo r/zFJSv2vn/+X+H/ANtf+YpKV+18/wD8v8P/ALa/8xSUr9r5/wD5f4f/AG1/5ikpX7Xz/wDy/wAP SUu+vLDnuY2h24aFwIM6fS57BJTaSU5OT/4qunf+m/P/APP3TUlK+qf/AIlejf8Apvxf/PNaSnWS ), British Electricity International, in Turbines, Generators and Associated Plant (Third Edition), 1991. ANwJKV9vf+4ElK+3v/cCSlfb3/uBJSvt7/3AkpX29/7gSUr7e/8AcCSlfb3/ALgSUr7e/wDcCSlf In 1997, an in-house redesign was undertaken to improve reliability. The tank volume is varied as follows: Case 1 V=0.3m3, Case 2 0.03m3, Case 3 0.1m3, Case 4 0.6m3. d|. %PDF-1.4

%

JStjP3R9ySlbGfuj7klK2M/dH3JKVsZ+6PuSUrYz90fckpWxn7o+5JStjP3R9ySlbGfuj7klK2M/ endstream

endobj

55 0 obj

<>>>

endobj

56 0 obj

<>

endobj

57 0 obj

<>

endobj

58 0 obj

<>/Font<>/ProcSet[/PDF/Text/ImageB]/Properties<>>>/XObject<>>>/Rotate 0/TrimBox[0.0 0.0 595.276 841.89]/Type/Page>>

endobj

59 0 obj

<>

endobj

60 0 obj

<>stream

The forward planetary carrier is attached to the output shaft so that the planet gears drive the sun gear instead of walking around the sun gear. Adobe PDF Library 8.0 SEVEN OCEAN HYDRAULIC INDUSTRIAL CO., LTD. - Our engineering expertise ensures we always seek new ways to innovate and create growth potential for Seven Ocean and our customers. constant enthalpy). NG16 / Cetop-7 / D07 Modular Stack Throttle Check Valve. Let X be the fraction of liquid at pressure PB with an enthalpy hLB. Ltd. All rights reserved. SSlJKUkpSSnJyf8AxVdO/wDTfn/+fumpKV9U/wDxK9G/9N+L/wCea0lOskpSSlJKUkpSSlJKUkpS As a result, repacking each turbine's steam glands every 4 months was necessary. At point B, the enthalpy of the saturated liquid is hLB, while the corresponding saturated vapor enthalpy is hVB. The heat balance equation, and the fraction of liquid formed are: M. Lucquiaud, in Ultra-Supercritical Coal Power Plants, 2013. Valve stem wear has been reduced and steam leaks at this location have been eradicated. ySnIv+qnQMi6zIuxd1lrnWPd6lglzjJMB4HJSUw/5nfVz/uJ/wCC2/8ApRJS/wDzP+rkR9k0/wCN 0000010975 00000 n

72.00 1uMgHVjjI5SU1f8Annnf9xMX/wBjaf8AySSlf8887/uJi/8AsbT/AOSSU9H0zLfnYNWXY1rHWgkt X9Wf/E30n/wjjf8AnpiSnSSU8zl/W3Ixsu7HbjscKbH1gknXaS2fwSUh/wCeeT/3Gr/zikpX/PPJ

%PDF-1.4 % em//ALg9F/7cb/5JJSvTf/3B6L/243/ySSlem/8A7g9F/wC3G/8AkklK9N//AHB6L/243/ySSlem 2.7) is generally employed where the required flow rate deviates from the nominal flow for short periods of operation. Z/SjWElI/wBo/XP/AEeF/nt/9KpKem+043+lZ/nD+9JSvtON/pWf5w/vSUr7Tjf6Vn+cP70lK+04 the axial thrust changes for single flow turbines, increased blade bending moments) and possibly also flow restrictions. We use cookies to help provide and enhance our service and tailor content and ads. /wD7g9F/7cb/AOSSU631daW5Vs4/T6P0f0sJ4c86jR0OOiSml1jL6r03LLLc2totmytrcUWQ0kwC 0lOskpAc3HaS0uMgkH2u5Bg9klLfbsb94/5rv/IpKV9uxv3j/mu/8ikpX27G/eP+a7/yKSlfbsb9 Pressure, left and mass, right in both tanks while changing speed from 3000 to 6000rpm and back to 3000.

default Fig. JPEG 9K/3W2NFh9x1eN30vFJSHY//ALg9F/7cb/5JJSvTd/3B6L/243/ySSlvTf8A9wei/wDbjf8AySSl 3Gj/AMikpXqdK/8AL2r/ANxo/wDIpKV6nSv/AC9q/wDcaP8AyKSlep0r/wAvav8A3Gj/AMikp3sH Modular Throttle Check Valve | hydraulic valves manufacturer - SEVEN OCEAN HYDRAULICS. Torque is then transmitted via the intermediate shaft to the forward planetary gear set which are then locked together by the engagement of the high and reverse clutch and the forward clutch. LPK1/lH+9JSv+bFv/lnlf5x/vSUr/mxb/wCWeV/nH+9JTstpqa0Da0wImAkpkK6wZDWg+IASUySU Dr. Breit Throttle Valves are now available at Hydraulic Systems Pte Ltd. Throttle valves are best used in flow metering while adjusting the required flow of the needle valve. 0000102997 00000 n In Figure 17-4, point A represents the bubble point at its saturation pressure, PA and enthalpy hLA. This system eliminates the losses in the valve when the plant operates at base load. AE35/wD5+6akpy/qz/4m+k/+Ecb/AM9MSU6SSlJKUkpSSlJKUkpSSlJKUkpSSlJKUkpSSlJKSUfz It is only a question of the time for it to reach its final value: for a tank of 30 litres it will be 2seconds, for 600 litres about 2minutes. 2016-03-04T07:49:55+01:00 eB6l1uhv1ss6Bm4wsoc4xY6Zl8uBDvCYCSnmOsVV0Z2VTXoxlr2tkzoHGElObj2RkBvYtP4JKfQP Seven Ocean Hydraulics MTC-02 Single / Double on Port A and/or B Throttle Check Valve Brochure - MTC-02. Conversely, if pressure if the starting tank pressure is above 4.2 bars, the pressure and temperature will rapidly fall to their final values. QiMkFVLBYjM0coLRQwclklPw4fFjczUWorKDJkSTVGRFwqN0NhfSVeJl8rOEw9N14/NGJ5SkhbSV 0000000016 00000 n From an efficiency standpoint, turbocharging is considered the preferred option. Adobe InDesign CC 2015 (Windows) Seven Ocean to participate at TFPE- Taipei International Fluid Power Exhibition at booth #Q319.

Figure8. adobe:docid:indd:22e0bf0b-98cd-11dc-9b5e-d79d4f4c7dfb 8/8A8v8AD/7a/wDMUlK/a+f/AOX+H/21/wCYpKbfTeu102ud1PrGNkVlsNaxmwh08zCSnR/5y9B/ xk6hJTvJKcnJ/wDFV07/ANN+f/5+6akpX1T/APEr0b/034v/AJ5rSU6ySloHgkpQa0cAfckpdJS0 /Kbp/wD7C0/+k0lK/wCaf1V/8pun/wDsLT/6TSUr/mn9Vf8Aym6f/wCwtP8A6TSUr/mn9Vf/ACm6 1c/7if8Agtv/AKUSUr/md9XP+4n/AILb/wClElLj6n/VwEEYmo/4W3/0okptdP6F0rpVrrsCj0nv SEVEN OCEAN HYDRAULICS has been offering customers high-quality hydraulic valves, both with advanced technology and 31 years of experience, SEVEN OCEAN HYDRAULICS ensures each customer's demands are met.

SiSlf87Pqr/5c9P/APYqn/0okpX/ADs+qv8A5c9P/wDYqn/0okpX/Oz6q/8Alz0//wBiqf8A0okp converted The wide flammability limits of hydrogen are an advantage for the load control strategy, since they allow a qualitative load control strategy, which avoids throttling in the intake manifold and the corresponding pumping losses. 0tB7UlOZ1nM6FfmEUdRqwnVlzLWfYvV3PDjucXFiSmh6nSv/AC9q/wDcaP8AyKSlep0r/wAvav8A Behavior of Centrifugal Pumps in Operation, Centrifugal Pump Handbook (Third Edition), Energy and Exergy Analyses of Natural Gas Liquefaction Cycles, Practical Machinery Management for Process Plants, Advanced Vehicle Technology (Second Edition), Update on the Progress of Hydrogen-Fueled Internal Combustion Engines, Turbines, Generators and Associated Plant (Third Edition), Whilst the effect of pressure drop is useful in, Ludwig's Applied Process Design for Chemical and Petrochemical Plants (Fourth Edition), This operation involves the proper functioning of an expansion valve or, CO2 capture-ready ultra-supercritical coal power plants, Unlike the previous option, the extraction pressure is not controlled by a, Lube, Seal and Control Oil System Best Practices, Forsthoffer's Best Practice Handbook for Rotating Machinery, Numerical analysis of unsteady behaviour of a screw compressor plant system, 8th International Conference on Compressors and their Systems. In Equation 4-30, ex denotes the expander efficiency.

/wDpNJSv+af1V/8AKbp//sLT/wCk0lK/5p/VX/ym6f8A+wtP/pNJSv8Amn9Vf/Kbp/8A7C0/+k0l Then a two tank model results were presented which enables to closed cycle systems. FIGURE 16.5. 2007-11-20T08:00:49+01:00 Recirculation of exhaust gases back to the intake of the engine is another way to reduce the power output for part-load operation without throttling. Refer to catalogs for more details. APn7pqSlfVP/AMSvRv8A034v/nmtJTrJKeSzX5AzLw2/oTR6r4F5Hqj3H+c0+l4+aSkO/J5+0fV7 Generally, sufficient accuracy is obtained by using the version given in Equation (1.2) where steam is the working fluid. D+0Vt3ONtVUBjrCPVsbXIYyHOjdwElOXg/W6vLxfWdjPa8VPvBlrazW31yxznvfDC5lMlrvok7Sd Using a throttle valve results in poor part-load efficiency, because the partially closed valve represents a resistance for the flow (pumping losses), which requires work from the engine. xmp.did:01801174072068119109AD89F6C6F738 xMJhrxKK6W8RW0N++ElOd6P6wkp636p/+JXo3/pvxf8AzzWkpv5X0B8UlPOZH1dtvvsuHUcmsWPc xmp.did:0180117407206811A961ACF9733D8886 0000020667 00000 n n/0okpX/ADs+qv8A5c9P/wDYqn/0okpX/Oz6q/8Alz0//wBiqf8A0okpX/Oz6q/+XPT/AP2Kp/8A 2007-11-20T08:00:49+01:00 endstream endobj 5 0 obj <> endobj 6 0 obj <> endobj 3 0 obj <> endobj 10 0 obj <>/Font<>/ProcSet[/PDF/Text/ImageB]/Properties<>/XObject<>>>/TrimBox[0.0 0.0 595.276 793.701]/Type/Page>> endobj 11 0 obj <>/Font<>/ProcSet[/PDF/Text]/XObject<>>>/TrimBox[0.0 0.0 595.276 793.701]/Type/Page>> endobj 12 0 obj <>/Font<>/ProcSet[/PDF/Text]/Properties<>/XObject<>>>/TrimBox[0.0 0.0 595.276 793.701]/Type/Page>> endobj 13 0 obj <>/ExtGState<>/Font<>/ProcSet[/PDF/Text]/Properties<>/XObject<>>>/TrimBox[0.0 0.0 595.276 793.701]/Type/Page>> endobj 14 0 obj <>/Font<>/ProcSet[/PDF/Text]/XObject<>>>/TrimBox[0.0 0.0 595.276 793.701]/Type/Page>> endobj 15 0 obj <>/ExtGState<>/Font<>/ProcSet[/PDF/Text]/Properties<>/XObject<>>>/TrimBox[0.0 0.0 595.276 793.701]/Type/Page>> endobj 16 0 obj <>/ExtGState<>/Font<>/ProcSet[/PDF/Text]/Properties<>/XObject<>>>/TrimBox[0.0 0.0 595.276 793.701]/Type/Page>> endobj 17 0 obj <>/Font<>/ProcSet[/PDF/Text]/XObject<>>>/TrimBox[0.0 0.0 595.276 793.701]/Type/Page>> endobj 76 0 obj [80 0 R 81 0 R] endobj 77 0 obj <>stream The torque then passes from the forward planet carrier to the output shaft. 3+lZ/nD+9JSvtON/pWf5w/vSUr7Tjf6Vn+cP70lK+043+lZ/nD+9JTJltVhit7XEc7SD+RJTmZP/

5.3 (ae). YHl2o9pAcdElI/rJV1KzKqOE3OLBX7vsdwqbMn6Qg6pKcj7N179zrH/sUP8AyKSlfZuvfudY/wDY /wC41f8AnFJSv+eeT/3Gr/zikpX/ADzyf+41f+cUlK/555P/AHGr/wA4pKV/zzyf+41f+cUlOj0P Alternatively, the IP turbine can be modified as part of the conversion to better match its new operating conditions. UX:v*cmCHW)g*n(<>:";:$(.^~4w$BF8'4=Q|aBv\;=A)XS)@ #WklS:ET[D0n\:Pwc5)Y~JA#tzgNK=]d:]nmR=oz5,L_R*+Z}b!NR\=b0SgK0Sdo}JaBulO@d/(>]>HZ9ve-2}).P)UA)Z@}H`l$DnTrZGW:SD!F mH+M"~gz})kR|X$1NUB7u@ZpDGkr:wRj]"[(q?Q1@Yrx+L~\OEB62-7D$nAom/T4/3XUr-O[-:dRQ3pa~Mc'T?VotBbIA~R9?0yRhk*L|ylrJUYTd.Qwx(denzSu v_E4[59K@|*RTckS\^fU8__sx/qz=iapMs,VZ0\Eq&o;uShD~[bG`fnlmOYLax{#$`F,rV"Dx

&TQi\* It is meant for controlling flow in one direction in the system by throttle of flow and allows free flow in the opposite direction.

5.3 (ae). YHl2o9pAcdElI/rJV1KzKqOE3OLBX7vsdwqbMn6Qg6pKcj7N179zrH/sUP8AyKSlfZuvfudY/wDY /wC41f8AnFJSv+eeT/3Gr/zikpX/ADzyf+41f+cUlK/555P/AHGr/wA4pKV/zzyf+41f+cUlOj0P Alternatively, the IP turbine can be modified as part of the conversion to better match its new operating conditions. UX:v*cmCHW)g*n(<>:";:$(.^~4w$BF8'4=Q|aBv\;=A)XS)@ #WklS:ET[D0n\:Pwc5)Y~JA#tzgNK=]d:]nmR=oz5,L_R*+Z}b!NR\=b0SgK0Sdo}JaBulO@d/(>]>HZ9ve-2}).P)UA)Z@}H`l$DnTrZGW:SD!F mH+M"~gz})kR|X$1NUB7u@ZpDGkr:wRj]"[(q?Q1@Yrx+L~\OEB62-7D$nAom/T4/3XUr-O[-:dRQ3pa~Mc'T?VotBbIA~R9?0yRhk*L|ylrJUYTd.Qwx(denzSu v_E4[59K@|*RTckS\^fU8__sx/qz=iapMs,VZ0\Eq&o;uShD~[bG`fnlmOYLax{#$`F,rV"Dx

&TQi\* It is meant for controlling flow in one direction in the system by throttle of flow and allows free flow in the opposite direction. e KV+I@I|U1_-L`SNkiC^i`GWR,)NL MQ*l5& A. Kayode Coker, in Ludwig's Applied Process Design for Chemical and Petrochemical Plants (Fourth Edition), 2015. 94 0 obj <>stream HWms|[ g2qKXv.thxDbY Eq^ze3NWt, 7ey&c'V&__H5ts&_'$:Z#Yrkk-''`uY4Wg3j'S4cY7jYj4(+6[MN\]vpaIrn60NT$$cy[lualrv^]K)M2Asf5+GU}D!dYu? The engine performance provided by the load control strategy mentioned above is shown in the map in Fig. Arrangements for future steam extraction are similar to arrangements for the previous option. Since the expansion step (AB) occurs across the expansion valve and no energy has been exchanged, the process is considered to be isenthalpic (i.e. 0000252574 00000 n %PDF-1.4 % 0000021771 00000 n 0000001805 00000 n This resulted in the following design and operational improvements: Figure 13-2. Copyright 2017 Hydraulic Systems Pte.

xmp.id:e839fe14-f041-8842-adbb-5eb883ce69f6 6q/+XPT/AP2Kp/8ASiSlf87Pqr/5c9P/APYqn/0okpX/ADs+qv8A5c9P/wDYqn/0okpX/Oz6q/8A The packing glands on all eight turbines have still not required repacking after 3 years of continuous operation. Because of isenthalpic throttling, h1=h2, thus the exergy loss can be expressed as, For an expander, the exergy loss based on Equation 2-23b is, where e1 and e2 are the specific exergy before and after the expansion; and We is the output work from the expander, and We=me(h2h1). Figure 2.7. MTC-03: NG10 / Cetop-5 / NFPA-D05

In Figure 17-4, point B is inside the envelope, where liquid and vapor coexist. Seven Ocean Hydraulics MTC series valve is used for actuator speed control. 6y/VfCx2VNymbw1ossZjvr9RzRBcWtr7pKbH/PH6uf8Acv8A8Ct/9JpKb3Tur9P6s17un2+sKiA/ interference fit, using molybdenum disulfide grease. With the selector lever in reverse position all three clutches and the low and reverse multiplate brake are engaged. The initial IP/LP crossover pressure is set so that, when the predicted amount of steam is extracted for solvent regeneration, its pressure falls or floats to the desired value, as indicated in Fig. Combination of throttle valve and check valvesuch that the hydraulic fluid flow in one direction must flow through the throttle (and is reduced in the process), while in the other direction the hydraulic fluid flows unthrottled via the check valve. 0000005650 00000 n

SlJKUkpSSlJKUkpSSlJKUkpSSlJKUkpSSlJKcnJ/8VXTv/Tfn/8An7pqSlfVP/xK9G/9N+L/AOea The resulting variation of mass contained in the tanks with time is presented in Figure8 right. [9!M/X2&w/V#gR$@$$IyJ,~p^g_npk!jEv z6R#1H"12Z%(;{6OS ~3}&@uBo&>pmZHDV3VW2]VIp"a 2007-11-20T07:59:18+01:00 /tSU6GLlOysdt+19W+fZZo4QSNR8klJdzvEpKVud4lJStzvEpKVud4lJStzvEpKVud4lJStzvEpK 0000103271 00000 n

Therefore, the fraction of the vapor formed during the expansion process with an enthalpy hVB is (1X). Dnj47UlPOZD+CTJlJTqR/kr1P+B/hCSn1r6p/wDiV6N/6b8X/wA81pKb+V9AfFJTlP6v0up7q7Mq Clutch and brake engagement sequence. kpLi9Q+thyaRlNw20GxotLXtkMkbiP0p7JKeh+043+lZ/nD+9JSvtON/pWf5w/vSUr7Tjf6Vn+cP Figure6. 0000026385 00000 n

The lantern ring is now an integral part of the valve stem bushing. zP6wSU6iSlJKUkpSSlJKUkpycn/xVdO/9N+f/wCfumpKcv6s/wDib6T/AOEcb/z0xJTpJKUkpSSl 4DlJTQ/buf8A9zm/+wX/AJikpX7dz/8Auc3/ANgv/MUlK/buf/3Ob/7Bf+YpKV+3c/8A7nN/9gv/ Figure5. This is 4.2bar in all cases, as presented in Figure5. The results are presented in groups, showing the effects of varying the throttle valve area, the tank volume and the tank pressure, as well as by varying the compressor shaft speed. Graphic Symbol - MTC-02 - P Throttle Check Valve. At the same time the second gear band brake holds the double sun gear and reverse pinion carrier stationary. The best performance with capture is obtained if the extraction steam flow with capture is guessed correctly, but higher and lower steam extraction flows can be accommodated if valves are used downstream of the extraction tee or in the extraction line, respectively. From the diagrams in Figure3 it can be seen how the pressure and temperature change for different valve areas. Therefore the overdrive pinion gears are prevented from rotating on their axes, causing the overdrive gear set to revolve as a whole without any gear ratio reduction at this stage. 256 As a result, the mass flow rate to Tank 2 doubles immediately, but the flow rate from Tank 2 into Tank 1 needs some time to reach this value, as a result of the increase of pressure in Tank 2, as shown in Figure7 right. 5.4(ae). In Handbook of Liquefied Natural Gas, 2014, The exergy loss in a throttle valve can be written as, where e1 and e2 are the specific exergy before and after the throttle process. Note: The inner, high-pressure bushing was retained as is. Hydraulic Configuration - MTC - Throttle Check Valve, Single Acting on Port P. Hydraulic Configuration - MTC - Throttle Check Valve, Single or Double Acting on Port A and / or B. AIqunf8Apvz/APz901JSvqn/AOJXo3/pvxf/ADzWkp1klPLZnVc2vMvrZ1zEpayx7RU6qXMAcRtJ A relationship between mass flow and the fall in pressure across the turbine was first produced by Stodola in 1927 [4]. However, for parallel flow path the reverse flow will be blocked if you are equipped with a check valve. ?dy*\vSLDY,5 A two tank plant model was then developed to enable closed systems to be simulated. HlW$

WYg-y

Y,SU$d0_{o[8?~zK;xv:1Y>n/|^O9vquPYKU^[?j+0{``1Ncu@0q0u.02p- si`S2N1:Ri]A[FXhUkmcmLcN8Bz+ Bc&AX#LL66Ap#DtokW|zG0QDZ!E

Y9?neA;Fz}7>IPa[xf &6{;GU}s4z. By continuing you agree to the use of cookies. The pressure in the tank was varied as follows: Case 1 p2=1bar, Case 2 3bar, Case 3 5bar, Case 4 7bar. It can be seen from the diagrams in Figure4 that for a given throttle valve area, the final discharge pressure will be the same for different tank volumes. EhMTExIYFBIUFBQUEhQUGx4eHhsUJCcnJyckMjU1NTI7Ozs7Ozs7Ozs7AQ0LCxAOECIYGCIyKCEo r/zFJSv2vn/+X+H/ANtf+YpKV+18/wD8v8P/ALa/8xSUr9r5/wD5f4f/AG1/5ikpX7Xz/wDy/wAP SUu+vLDnuY2h24aFwIM6fS57BJTaSU5OT/4qunf+m/P/APP3TUlK+qf/AIlejf8Apvxf/PNaSnWS ), British Electricity International, in Turbines, Generators and Associated Plant (Third Edition), 1991. ANwJKV9vf+4ElK+3v/cCSlfb3/uBJSvt7/3AkpX29/7gSUr7e/8AcCSlfb3/ALgSUr7e/wDcCSlf In 1997, an in-house redesign was undertaken to improve reliability. The tank volume is varied as follows: Case 1 V=0.3m3, Case 2 0.03m3, Case 3 0.1m3, Case 4 0.6m3. d|. %PDF-1.4

%

JStjP3R9ySlbGfuj7klK2M/dH3JKVsZ+6PuSUrYz90fckpWxn7o+5JStjP3R9ySlbGfuj7klK2M/ endstream

endobj

55 0 obj

<>>>

endobj

56 0 obj

<>

endobj

57 0 obj

<>

endobj

58 0 obj

<>/Font<>/ProcSet[/PDF/Text/ImageB]/Properties<>>>/XObject<>>>/Rotate 0/TrimBox[0.0 0.0 595.276 841.89]/Type/Page>>

endobj

59 0 obj

<>

endobj

60 0 obj

<>stream

The forward planetary carrier is attached to the output shaft so that the planet gears drive the sun gear instead of walking around the sun gear. Adobe PDF Library 8.0 SEVEN OCEAN HYDRAULIC INDUSTRIAL CO., LTD. - Our engineering expertise ensures we always seek new ways to innovate and create growth potential for Seven Ocean and our customers. constant enthalpy). NG16 / Cetop-7 / D07 Modular Stack Throttle Check Valve. Let X be the fraction of liquid at pressure PB with an enthalpy hLB. Ltd. All rights reserved. SSlJKUkpSSnJyf8AxVdO/wDTfn/+fumpKV9U/wDxK9G/9N+L/wCea0lOskpSSlJKUkpSSlJKUkpS As a result, repacking each turbine's steam glands every 4 months was necessary. At point B, the enthalpy of the saturated liquid is hLB, while the corresponding saturated vapor enthalpy is hVB. The heat balance equation, and the fraction of liquid formed are: M. Lucquiaud, in Ultra-Supercritical Coal Power Plants, 2013. Valve stem wear has been reduced and steam leaks at this location have been eradicated. ySnIv+qnQMi6zIuxd1lrnWPd6lglzjJMB4HJSUw/5nfVz/uJ/wCC2/8ApRJS/wDzP+rkR9k0/wCN 0000010975 00000 n

72.00 1uMgHVjjI5SU1f8Annnf9xMX/wBjaf8AySSlf8887/uJi/8AsbT/AOSSU9H0zLfnYNWXY1rHWgkt X9Wf/E30n/wjjf8AnpiSnSSU8zl/W3Ixsu7HbjscKbH1gknXaS2fwSUh/wCeeT/3Gr/zikpX/PPJ

SlJKUkpSSlJKUkpSSlJKUkpSSlJKUkpSSlJKcnJ/8VXTv/Tfn/8An7pqSlfVP/xK9G/9N+L/AOea The resulting variation of mass contained in the tanks with time is presented in Figure8 right. [9!M/X2&w/V#gR$@$$IyJ,~p^g_npk!jEv z6R#1H"12Z%(;{6OS ~3}&@uBo&>pmZHDV3VW2]VIp"a 2007-11-20T07:59:18+01:00 /tSU6GLlOysdt+19W+fZZo4QSNR8klJdzvEpKVud4lJStzvEpKVud4lJStzvEpKVud4lJStzvEpK 0000103271 00000 n

Therefore, the fraction of the vapor formed during the expansion process with an enthalpy hVB is (1X). Dnj47UlPOZD+CTJlJTqR/kr1P+B/hCSn1r6p/wDiV6N/6b8X/wA81pKb+V9AfFJTlP6v0up7q7Mq Clutch and brake engagement sequence. kpLi9Q+thyaRlNw20GxotLXtkMkbiP0p7JKeh+043+lZ/nD+9JSvtON/pWf5w/vSUr7Tjf6Vn+cP Figure6. 0000026385 00000 n

The lantern ring is now an integral part of the valve stem bushing. zP6wSU6iSlJKUkpSSlJKUkpycn/xVdO/9N+f/wCfumpKcv6s/wDib6T/AOEcb/z0xJTpJKUkpSSl 4DlJTQ/buf8A9zm/+wX/AJikpX7dz/8Auc3/ANgv/MUlK/buf/3Ob/7Bf+YpKV+3c/8A7nN/9gv/ Figure5. This is 4.2bar in all cases, as presented in Figure5. The results are presented in groups, showing the effects of varying the throttle valve area, the tank volume and the tank pressure, as well as by varying the compressor shaft speed. Graphic Symbol - MTC-02 - P Throttle Check Valve. At the same time the second gear band brake holds the double sun gear and reverse pinion carrier stationary. The best performance with capture is obtained if the extraction steam flow with capture is guessed correctly, but higher and lower steam extraction flows can be accommodated if valves are used downstream of the extraction tee or in the extraction line, respectively. From the diagrams in Figure3 it can be seen how the pressure and temperature change for different valve areas. Therefore the overdrive pinion gears are prevented from rotating on their axes, causing the overdrive gear set to revolve as a whole without any gear ratio reduction at this stage. 256 As a result, the mass flow rate to Tank 2 doubles immediately, but the flow rate from Tank 2 into Tank 1 needs some time to reach this value, as a result of the increase of pressure in Tank 2, as shown in Figure7 right. 5.4(ae). In Handbook of Liquefied Natural Gas, 2014, The exergy loss in a throttle valve can be written as, where e1 and e2 are the specific exergy before and after the throttle process. Note: The inner, high-pressure bushing was retained as is. Hydraulic Configuration - MTC - Throttle Check Valve, Single Acting on Port P. Hydraulic Configuration - MTC - Throttle Check Valve, Single or Double Acting on Port A and / or B. AIqunf8Apvz/APz901JSvqn/AOJXo3/pvxf/ADzWkp1klPLZnVc2vMvrZ1zEpayx7RU6qXMAcRtJ A relationship between mass flow and the fall in pressure across the turbine was first produced by Stodola in 1927 [4]. However, for parallel flow path the reverse flow will be blocked if you are equipped with a check valve. ?dy*\vSLDY,5 A two tank plant model was then developed to enable closed systems to be simulated. HlW$

WYg-y

Y,SU$d0_{o[8?~zK;xv:1Y>n/|^O9vquPYKU^[?j+0{``1Ncu@0q0u.02p- si`S2N1:Ri]A[FXhUkmcmLcN8Bz+ Bc&AX#LL66Ap#DtokW|zG0QDZ!E

Y9?neA;Fz}7>IPa[xf &6{;GU}s4z. By continuing you agree to the use of cookies. The pressure in the tank was varied as follows: Case 1 p2=1bar, Case 2 3bar, Case 3 5bar, Case 4 7bar. It can be seen from the diagrams in Figure4 that for a given throttle valve area, the final discharge pressure will be the same for different tank volumes. EhMTExIYFBIUFBQUEhQUGx4eHhsUJCcnJyckMjU1NTI7Ozs7Ozs7Ozs7AQ0LCxAOECIYGCIyKCEo r/zFJSv2vn/+X+H/ANtf+YpKV+18/wD8v8P/ALa/8xSUr9r5/wD5f4f/AG1/5ikpX7Xz/wDy/wAP SUu+vLDnuY2h24aFwIM6fS57BJTaSU5OT/4qunf+m/P/APP3TUlK+qf/AIlejf8Apvxf/PNaSnWS ), British Electricity International, in Turbines, Generators and Associated Plant (Third Edition), 1991. ANwJKV9vf+4ElK+3v/cCSlfb3/uBJSvt7/3AkpX29/7gSUr7e/8AcCSlfb3/ALgSUr7e/wDcCSlf In 1997, an in-house redesign was undertaken to improve reliability. The tank volume is varied as follows: Case 1 V=0.3m3, Case 2 0.03m3, Case 3 0.1m3, Case 4 0.6m3. d|. %PDF-1.4

%

JStjP3R9ySlbGfuj7klK2M/dH3JKVsZ+6PuSUrYz90fckpWxn7o+5JStjP3R9ySlbGfuj7klK2M/ endstream

endobj

55 0 obj

<>>>

endobj

56 0 obj

<>

endobj

57 0 obj

<>

endobj

58 0 obj

<>/Font<>/ProcSet[/PDF/Text/ImageB]/Properties<>>>/XObject<>>>/Rotate 0/TrimBox[0.0 0.0 595.276 841.89]/Type/Page>>

endobj

59 0 obj

<>

endobj

60 0 obj

<>stream

The forward planetary carrier is attached to the output shaft so that the planet gears drive the sun gear instead of walking around the sun gear. Adobe PDF Library 8.0 SEVEN OCEAN HYDRAULIC INDUSTRIAL CO., LTD. - Our engineering expertise ensures we always seek new ways to innovate and create growth potential for Seven Ocean and our customers. constant enthalpy). NG16 / Cetop-7 / D07 Modular Stack Throttle Check Valve. Let X be the fraction of liquid at pressure PB with an enthalpy hLB. Ltd. All rights reserved. SSlJKUkpSSnJyf8AxVdO/wDTfn/+fumpKV9U/wDxK9G/9N+L/wCea0lOskpSSlJKUkpSSlJKUkpS As a result, repacking each turbine's steam glands every 4 months was necessary. At point B, the enthalpy of the saturated liquid is hLB, while the corresponding saturated vapor enthalpy is hVB. The heat balance equation, and the fraction of liquid formed are: M. Lucquiaud, in Ultra-Supercritical Coal Power Plants, 2013. Valve stem wear has been reduced and steam leaks at this location have been eradicated. ySnIv+qnQMi6zIuxd1lrnWPd6lglzjJMB4HJSUw/5nfVz/uJ/wCC2/8ApRJS/wDzP+rkR9k0/wCN 0000010975 00000 n

72.00 1uMgHVjjI5SU1f8Annnf9xMX/wBjaf8AySSlf8887/uJi/8AsbT/AOSSU9H0zLfnYNWXY1rHWgkt X9Wf/E30n/wjjf8AnpiSnSSU8zl/W3Ixsu7HbjscKbH1gknXaS2fwSUh/wCeeT/3Gr/zikpX/PPJ %PDF-1.4 % em//ALg9F/7cb/5JJSvTf/3B6L/243/ySSlem/8A7g9F/wC3G/8AkklK9N//AHB6L/243/ySSlem 2.7) is generally employed where the required flow rate deviates from the nominal flow for short periods of operation. Z/SjWElI/wBo/XP/AEeF/nt/9KpKem+043+lZ/nD+9JSvtON/pWf5w/vSUr7Tjf6Vn+cP70lK+04 the axial thrust changes for single flow turbines, increased blade bending moments) and possibly also flow restrictions. We use cookies to help provide and enhance our service and tailor content and ads. /wD7g9F/7cb/AOSSU631daW5Vs4/T6P0f0sJ4c86jR0OOiSml1jL6r03LLLc2totmytrcUWQ0kwC 0lOskpAc3HaS0uMgkH2u5Bg9klLfbsb94/5rv/IpKV9uxv3j/mu/8ikpX27G/eP+a7/yKSlfbsb9 Pressure, left and mass, right in both tanks while changing speed from 3000 to 6000rpm and back to 3000.

default Fig. JPEG 9K/3W2NFh9x1eN30vFJSHY//ALg9F/7cb/5JJSvTd/3B6L/243/ySSlvTf8A9wei/wDbjf8AySSl 3Gj/AMikpXqdK/8AL2r/ANxo/wDIpKV6nSv/AC9q/wDcaP8AyKSlep0r/wAvav8A3Gj/AMikp3sH Modular Throttle Check Valve | hydraulic valves manufacturer - SEVEN OCEAN HYDRAULICS. Torque is then transmitted via the intermediate shaft to the forward planetary gear set which are then locked together by the engagement of the high and reverse clutch and the forward clutch. LPK1/lH+9JSv+bFv/lnlf5x/vSUr/mxb/wCWeV/nH+9JTstpqa0Da0wImAkpkK6wZDWg+IASUySU Dr. Breit Throttle Valves are now available at Hydraulic Systems Pte Ltd. Throttle valves are best used in flow metering while adjusting the required flow of the needle valve. 0000102997 00000 n In Figure 17-4, point A represents the bubble point at its saturation pressure, PA and enthalpy hLA. This system eliminates the losses in the valve when the plant operates at base load. AE35/wD5+6akpy/qz/4m+k/+Ecb/AM9MSU6SSlJKUkpSSlJKUkpSSlJKUkpSSlJKUkpSSlJKSUfz It is only a question of the time for it to reach its final value: for a tank of 30 litres it will be 2seconds, for 600 litres about 2minutes. 2016-03-04T07:49:55+01:00 eB6l1uhv1ss6Bm4wsoc4xY6Zl8uBDvCYCSnmOsVV0Z2VTXoxlr2tkzoHGElObj2RkBvYtP4JKfQP Seven Ocean Hydraulics MTC-02 Single / Double on Port A and/or B Throttle Check Valve Brochure - MTC-02. Conversely, if pressure if the starting tank pressure is above 4.2 bars, the pressure and temperature will rapidly fall to their final values. QiMkFVLBYjM0coLRQwclklPw4fFjczUWorKDJkSTVGRFwqN0NhfSVeJl8rOEw9N14/NGJ5SkhbSV 0000000016 00000 n From an efficiency standpoint, turbocharging is considered the preferred option. Adobe InDesign CC 2015 (Windows) Seven Ocean to participate at TFPE- Taipei International Fluid Power Exhibition at booth #Q319.

Figure8. adobe:docid:indd:22e0bf0b-98cd-11dc-9b5e-d79d4f4c7dfb 8/8A8v8AD/7a/wDMUlK/a+f/AOX+H/21/wCYpKbfTeu102ud1PrGNkVlsNaxmwh08zCSnR/5y9B/ xk6hJTvJKcnJ/wDFV07/ANN+f/5+6akpX1T/APEr0b/034v/AJ5rSU6ySloHgkpQa0cAfckpdJS0 /Kbp/wD7C0/+k0lK/wCaf1V/8pun/wDsLT/6TSUr/mn9Vf8Aym6f/wCwtP8A6TSUr/mn9Vf/ACm6 1c/7if8Agtv/AKUSUr/md9XP+4n/AILb/wClElLj6n/VwEEYmo/4W3/0okptdP6F0rpVrrsCj0nv SEVEN OCEAN HYDRAULICS has been offering customers high-quality hydraulic valves, both with advanced technology and 31 years of experience, SEVEN OCEAN HYDRAULICS ensures each customer's demands are met.

SiSlf87Pqr/5c9P/APYqn/0okpX/ADs+qv8A5c9P/wDYqn/0okpX/Oz6q/8Alz0//wBiqf8A0okp converted The wide flammability limits of hydrogen are an advantage for the load control strategy, since they allow a qualitative load control strategy, which avoids throttling in the intake manifold and the corresponding pumping losses. 0tB7UlOZ1nM6FfmEUdRqwnVlzLWfYvV3PDjucXFiSmh6nSv/AC9q/wDcaP8AyKSlep0r/wAvav8A Behavior of Centrifugal Pumps in Operation, Centrifugal Pump Handbook (Third Edition), Energy and Exergy Analyses of Natural Gas Liquefaction Cycles, Practical Machinery Management for Process Plants, Advanced Vehicle Technology (Second Edition), Update on the Progress of Hydrogen-Fueled Internal Combustion Engines, Turbines, Generators and Associated Plant (Third Edition), Whilst the effect of pressure drop is useful in, Ludwig's Applied Process Design for Chemical and Petrochemical Plants (Fourth Edition), This operation involves the proper functioning of an expansion valve or, CO2 capture-ready ultra-supercritical coal power plants, Unlike the previous option, the extraction pressure is not controlled by a, Lube, Seal and Control Oil System Best Practices, Forsthoffer's Best Practice Handbook for Rotating Machinery, Numerical analysis of unsteady behaviour of a screw compressor plant system, 8th International Conference on Compressors and their Systems. In Equation 4-30, ex denotes the expander efficiency.

/wDpNJSv+af1V/8AKbp//sLT/wCk0lK/5p/VX/ym6f8A+wtP/pNJSv8Amn9Vf/Kbp/8A7C0/+k0l Then a two tank model results were presented which enables to closed cycle systems. FIGURE 16.5. 2007-11-20T08:00:49+01:00 Recirculation of exhaust gases back to the intake of the engine is another way to reduce the power output for part-load operation without throttling. Refer to catalogs for more details. APn7pqSlfVP/AMSvRv8A034v/nmtJTrJKeSzX5AzLw2/oTR6r4F5Hqj3H+c0+l4+aSkO/J5+0fV7 Generally, sufficient accuracy is obtained by using the version given in Equation (1.2) where steam is the working fluid. D+0Vt3ONtVUBjrCPVsbXIYyHOjdwElOXg/W6vLxfWdjPa8VPvBlrazW31yxznvfDC5lMlrvok7Sd Using a throttle valve results in poor part-load efficiency, because the partially closed valve represents a resistance for the flow (pumping losses), which requires work from the engine. xmp.did:01801174072068119109AD89F6C6F738 xMJhrxKK6W8RW0N++ElOd6P6wkp636p/+JXo3/pvxf8AzzWkpv5X0B8UlPOZH1dtvvsuHUcmsWPc xmp.did:0180117407206811A961ACF9733D8886 0000020667 00000 n n/0okpX/ADs+qv8A5c9P/wDYqn/0okpX/Oz6q/8Alz0//wBiqf8A0okpX/Oz6q/+XPT/AP2Kp/8A 2007-11-20T08:00:49+01:00 endstream endobj 5 0 obj <> endobj 6 0 obj <> endobj 3 0 obj <> endobj 10 0 obj <>/Font<>/ProcSet[/PDF/Text/ImageB]/Properties<>/XObject<>>>/TrimBox[0.0 0.0 595.276 793.701]/Type/Page>> endobj 11 0 obj <>/Font<>/ProcSet[/PDF/Text]/XObject<>>>/TrimBox[0.0 0.0 595.276 793.701]/Type/Page>> endobj 12 0 obj <>/Font<>/ProcSet[/PDF/Text]/Properties<>/XObject<>>>/TrimBox[0.0 0.0 595.276 793.701]/Type/Page>> endobj 13 0 obj <>/ExtGState<>/Font<>/ProcSet[/PDF/Text]/Properties<>/XObject<>>>/TrimBox[0.0 0.0 595.276 793.701]/Type/Page>> endobj 14 0 obj <>/Font<>/ProcSet[/PDF/Text]/XObject<>>>/TrimBox[0.0 0.0 595.276 793.701]/Type/Page>> endobj 15 0 obj <>/ExtGState<>/Font<>/ProcSet[/PDF/Text]/Properties<>/XObject<>>>/TrimBox[0.0 0.0 595.276 793.701]/Type/Page>> endobj 16 0 obj <>/ExtGState<>/Font<>/ProcSet[/PDF/Text]/Properties<>/XObject<>>>/TrimBox[0.0 0.0 595.276 793.701]/Type/Page>> endobj 17 0 obj <>/Font<>/ProcSet[/PDF/Text]/XObject<>>>/TrimBox[0.0 0.0 595.276 793.701]/Type/Page>> endobj 76 0 obj [80 0 R 81 0 R] endobj 77 0 obj <>stream The torque then passes from the forward planet carrier to the output shaft. 3+lZ/nD+9JSvtON/pWf5w/vSUr7Tjf6Vn+cP70lK+043+lZ/nD+9JTJltVhit7XEc7SD+RJTmZP/