Click and listen to what moves the machining industry.

For applications in the electronics sector, we supply: DCB substrates, thick-film circuits, hybrid circuits, sensors, copper-plated ceramic substrates, printed circuit boards and flex printed circuit boards. In addition to much better wear protection, this provides a huge time advantage. ApplicationsVacuum metallizing process is used for decorative metallic finishes, EMI/RFI Shielding, and Reflective coatings on plastic, glass, and metal substrates. Quality proudly "Made in Germany", customer satisfaction and safeguarding customer processes are our guiding principles for order fulfilment and the development of new and innovative coating and spray paint systems. Die Division konzentriert sich auf technologisch anspruchsvolle Produktsegmente und ist weltweit Marktfhrer fr Werkzeugsthle und Sonderwerkstoffe.

Get top-quality coatings with a maximum of productivity and efficiency. Please note: VaporTech is purely an equipment manufacturer NOT a coating service provider. When machining hardened steels beyond 50 HRC, precision tools with SteelCon coatings achieve top performance. Under our ARADIERUNG brand, we offer a method for applying thin films in any colour you desire. The results are finishes that are resistant to chemicals, are easy to maintain, can protect against corrosion, and dramatically increase tool life. With extensive experience, knowledge and expertise, the Systec Group develops sector-specific solutions, which set new standards, not least because of its exceptional manufacturing quality. Hardware coating--decorative vacuum metallizing, Glass bangles decorative coating film-decorative vacuum coating, Stainless steel plate coating-decorative vacuum coating, Ceramics tile vacuum coating-decorative coating, Mosic tiles vacuum coating machine-decorative, Cutting toolings hard film coating-functional coating. With the in-house diamond coating line from CemeCon, Fraisa has become the jewel among tool manufacturers. We offer you the following services: Tool production to order. This includes surface cleaning and modification as well as coating and etching processes (PVD, PECVD, RIE, microwave). Do you need them to be inexpensive and environmentally friendly, and to save on resources? Quality for a fair price. Ourhigher-capacity lower-temperature thin film coating system. Gianluca Battiloro,General Manager of Sitim. Sorry, but this browser or your browser version is not supported. 14, DE-40595 Dsseldorf, Germany. The processes of chrome plating adopted by Kolzer machines, in addition to be at zero emission, use metallic chrome, therefore "zerovalent". pvd coater sputtering magnetron We have own producing line with professional technicians. Multiple coating sources can further increase deposition rates or deposit composite materials. pvd coatings 79 West Jinniu Road, Yuyao, Ningbo City, Zhejiang Provice, China, Thermal evaporation vacuum coating machine, Thermal evaporation & magnetron sputtering coating machine, Automotive light metallization coating machine, Automotive decorative parts coating machine, Automotive Lamp Reflector Film Vacuum Coating Machine, Thermal Evaporation Vacuum Coating Machine, Thermal Evaporation & Magnetron Sputtering Coating Machine. If you don't find the application you are looking for your products, we'll develop it for you! We use cookies on this website.

Get top-quality coatings with a maximum of productivity and efficiency. Please note: VaporTech is purely an equipment manufacturer NOT a coating service provider. When machining hardened steels beyond 50 HRC, precision tools with SteelCon coatings achieve top performance. Under our ARADIERUNG brand, we offer a method for applying thin films in any colour you desire. The results are finishes that are resistant to chemicals, are easy to maintain, can protect against corrosion, and dramatically increase tool life. With extensive experience, knowledge and expertise, the Systec Group develops sector-specific solutions, which set new standards, not least because of its exceptional manufacturing quality. Hardware coating--decorative vacuum metallizing, Glass bangles decorative coating film-decorative vacuum coating, Stainless steel plate coating-decorative vacuum coating, Ceramics tile vacuum coating-decorative coating, Mosic tiles vacuum coating machine-decorative, Cutting toolings hard film coating-functional coating. With the in-house diamond coating line from CemeCon, Fraisa has become the jewel among tool manufacturers. We offer you the following services: Tool production to order. This includes surface cleaning and modification as well as coating and etching processes (PVD, PECVD, RIE, microwave). Do you need them to be inexpensive and environmentally friendly, and to save on resources? Quality for a fair price. Ourhigher-capacity lower-temperature thin film coating system. Gianluca Battiloro,General Manager of Sitim. Sorry, but this browser or your browser version is not supported. 14, DE-40595 Dsseldorf, Germany. The processes of chrome plating adopted by Kolzer machines, in addition to be at zero emission, use metallic chrome, therefore "zerovalent". pvd coater sputtering magnetron We have own producing line with professional technicians. Multiple coating sources can further increase deposition rates or deposit composite materials. pvd coatings 79 West Jinniu Road, Yuyao, Ningbo City, Zhejiang Provice, China, Thermal evaporation vacuum coating machine, Thermal evaporation & magnetron sputtering coating machine, Automotive light metallization coating machine, Automotive decorative parts coating machine, Automotive Lamp Reflector Film Vacuum Coating Machine, Thermal Evaporation Vacuum Coating Machine, Thermal Evaporation & Magnetron Sputtering Coating Machine. If you don't find the application you are looking for your products, we'll develop it for you! We use cookies on this website.

SYSTEC develops and manufactures plant technology for PVD coating for high-temperature processes of up to 3000 C and plant technology for vacuum processes. Since 2018, we have also been impressing customers with unique automation solutions for processing high-voltage cables and automated installation of HV connector systems through our subsidiary Metzner E-Mobility. Manufacturer of mirror-polished, blasted, PVD-coated surfaces for stainless steels. Thanks to the optimization of the processes and the double doors system, it is a perfect machine for the simultaneous loading and unloading of the pieces, Kolzer machines series MK guarantee high performance, fast cycle time processes and high production volumes, ideal to integrate into the OEM production lines. pvd coating foxin exporter nanhai emerged

All Rights Reserved. 1876299.

PVD uses cathodic arc deposition and as puttering process to produce high-grade coatings. Support Service & PhilosophyAt CICEL, we stand behind our systems with a dedicated service team who can diagnose and provide support when required, allowing you to maximize the return on your investment. HHI HUBERT HEUSNER INDUSTRIEVERTRETUNGEN UND HANDEL. Giuseppe Vasta, Group Ceo of Khatod Optoelectronic. PVD is a preferred technology because it doesn't require a conductive substrate - the metal film can be applied to plastic, metal, or glass. The split frame lets you place the electrical cabinet and control unit in a separate room. We concentrate both in general and precision machining, development and construction of vacuum coaters and components, production and reconditioning of tools and improvement of quality of tools by deposition of superior PVD (Physical Vapor Deposition) and PECVD (Plasma Enhanced Chemical Vapor Deposition) coatings. 81C14, certification by ISO 9001:2000 quality management system, certification by ISO 9001:2008 quality management system, acquisition of ecological ultrasonic cleaning vacuum system for degreasing, research and development coating center established in cooperation with Comenius University, certification by EN ISO 3834-2:2005 quality management system, design and construction of proprietary PVD coating system based on a combination of filtered cathodic arc, DC magnetron sputtering and HiPIMS technologies, development of PVD tribological coatings W-DLC, development of nanolayered PVD coatings TiN/CrN ordered in a superlattice structure, certification by STN EN 15085-2:2008 quality management system, development of coatings for PROOF quality coins, completing the development of ARC cathodes with suppressed generation of macroparticles, development of upgraded tribological Cr-based coatingsfor piston rings, production of new coating equipment for coating of long components, development of new filtered ARC cathode for production of new types of coatings, development and construction of new type of rectangular magnetron for working in high vacuum.

At CICEL, we stand behind our systems with a dedicated service team who can diagnose and provide support when required, allowing you to maximize the return on your investment. Its offering includes precision tools and cutting materials for a diverse range of cutting and forming applications as well as services in the areas of tool reconditioning and tool management. 79 West Jinniu Road, Sprimag employs around 180 staff at its current headquarters in Kirchheim-Teck and also has sites in the USA and Mexico.

If you need a true or very dark black coating, youve to consider exploring the PVD option. Longmont, Colorado, USA. We deliver ordered stock goods quickly, competently and reliably within 24 hours. coating pvd teer coatings gx announce pvd coating vti redesigned newly From the initial installation and training to providing maintenance on existing equipment, we are here for you.Contact usfor more information on PVD vacuum Coatings machine or to request a quote. The most superior system quickly emerged: the CC800 HiPIMS. Your ultrafine coated surfaces benefit from extreme smoothness and density. The soldering machines and metering systems from our mechanical engineers can be used for a wide range of applications. The Target Shutter System helps you protect inactive targets from being contaminated in coating processes with more than one material.

In addition to our in-house production, we also offer a coating process using the customer's PVD equipment or transfers from contract coating companies. Suppliers reviewed by inspection services. Especially for medium-sized TOOL MANUFACTURERS, our coating technology is a SUSTAINABLE INVESTMENT to secure competitive advantages, as for example in India: With a new HiPIMS TURNKEY PROJECT, Accusharp Cutting Tools Pvt. | Which technology accelerates growth and our success? We are a young, rapidly expanding business. Expert team: Coating Service You have to explicitly consent to which non-essential cookies we may activate. PVD treatments in the fashion industry for a highly requested chrome effect on buttons, accessories, shoes and textiles. HiPIMS technology offers us virtually boundless possibilities in the development of specific coating solutions. Alibaba.com Site: International - Espaol - Portugus - Deutsch - Franais - Italiano - - P - - - - - Trk - Nederlands - ting Vit - Indonesian - , AliExpress Building on our expertise in component manufacturing, AURION also offers complete systems for plasma-enhanced surface treatment. I met Kolzer a few years ago when we were looking for a company that could give us access to new technology, because at that time, we relied on external services with poor quality and logistics problems. STATON,s.r.o., is a machinery company located in the northern Slovakia. When you purchase a PVD coating machine from VaporTech, you not only receive quality products but custom coating development, professional customer care, technical support, and even employee training.

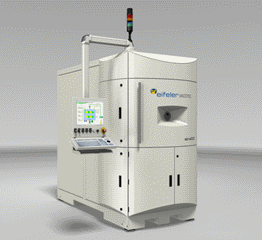

pvd coating system cycle minutes offers times under press You need JavaScript enabled to view it. Since its establishment in 1998, STATON,s.r.o. Even coating deposition rates throughout the chamber for excellent control of coating thickness. The partially chemical-based pretreatment procedures on the tool in the CVD diamond process constitute a slightly higher hurdle for a more mechanically aligned operation like Fraisa. The Supervisory Board and Executive Board have planned and prepared these changes for a long time. Buyer's engineer can come to our factory for machine and process training before delivery, also our engineer will visit customer's factory for professional training and installing the machine . With one of the largest warehouses in Germany and our in-house modification and production workshop, we ensure that every customer requirement is fulfilled. Able to coat large parts up to 122 cm (48 inches) long. VaporTech offers a range of PVD and PE-CVD machines designed for everything from high-volume, large-scale manufacturing to small-batch operations. 2022, voestalpine eifeler Unternehmensgruppe, Duderstdter Str. eifeler pvd Ltd. in Pune underlines with HiPIMS its role as INNOVATION LEADER.

coating pvd This has enabled us to take a HUGE STEP FORWARD in STAINLESS STEEL. CemeCon provides worldwide coating construction, coating services and coating systems from a single source. All of our orders are processed by us for a fair price. Once receive your question, the supplier will answer you as soon as possible. Kolzer machines guarantee versatility in Metallization and PVD Sputtering treatments as well as repeatability in production.Kolzer systems perform well in all conditions, with all materials and for processing on each substrate. Stay at the cutting edge with the latest information. Our easy-to-operate small to mid-sized lower-temperature thin film coating system. pvd | Affiliate, Product Listing Policy The equipment is available in a wide range of capacities, all with a small footprint for easy integration. Since 1925, Sprimag has been developing systems for the functional and decorative coating of mass-produced parts and for the internal coating of metal packaging. What are the common application fields of vacuum coating machine? Yuyao, Ningbo City, Zhejiang Provice, China. Join us now so you too can be visible on Europages. The main focus is in the field of high-frequency plasma processes at 13.5627.12 MHz. AURION develops and constructs components which supply power to plasma systems. This saves you precious time, as you need fewer cleaning cycles. Multiple system sizes right-sized and competitively priced for low as well as high and medium-volume manufacturing. The control of the microstructure guarantees perfect adhesion to surfaces. Coating development, system integration, training & support. Please use a browser that is not outdated. Using the same chamber to produce functional, decorative, and even DLC coatings, our equipment gives you a competitive edge. 06189250969, REA nr. VaporTech VTi-Series PVD coating machines utilize a unique, centrally mounted coating source with parts that rotate around the perimeter of a large, actively cooled chamber. What is the next step? Today, a large team of engineers and technicians works on the finishing of high profile tools. LMT Tools brings together the expertise of leading specialists in precision tool technology.