One of the major benefits of laser cutting is the precision, accuracy, and repeatability, and we are able to provide dimensional accuracy of 0.13mm, and a laser kerf (the amount which the cut width deviates) of between 0mm and 0.2mm depending on the thickness. And always we will send it.Of course, it needs to be "prepared" for the long trip, so we package it well.Hopefully, there is no damage to Your metal part, so you can enjoy it. The combination of these key attributes results in exceptional performance and customer satisfaction. As vehicles are increasingly required to maximise MPG, carmakers have to either improve fuel efficiency or reduce the weight of vehicles. It is used to build anything from modern furniture to high reliability satellite parts. Chicago Metal Rolled Products can produce full cylinders (360) or cylinder segments from curved sheet metal from 12 to 28 gauge.

Once the tools are in place, making subsequent sheet parts in production is very cost-effective. Thank you for great service!, Ive worked with CMRP for over 16 years and can rely on them for any size job and in any time frame. Innovative Metal Designs (IMD) is a world-class job shop specializing in high-speed machining, fabrication and assembly of component parts. ", Your group is awesome to work with and greatly appreciated!

Once the tools are in place, making subsequent sheet parts in production is very cost-effective. Thank you for great service!, Ive worked with CMRP for over 16 years and can rely on them for any size job and in any time frame. Innovative Metal Designs (IMD) is a world-class job shop specializing in high-speed machining, fabrication and assembly of component parts. ", Your group is awesome to work with and greatly appreciated!

eMachineShop regularly bends ductile metals such as Aluminum 5052 up to 0.25 thick. The fit of the two parts in AWESOME! I'm looking forward to ordering from you again. chroming logam syarat sheetmetalstampingparts This design aid demonstrates part features that are too thin or too thick, bad bosses, right and wrong ribs, and other considerations to be mindful of while designing parts for injection molding. Using a laser cutter with sheet metal is a great method for producing high-quality parts whether it is a prototype or a full-scale production run. I ordered the same pieces from different vendors to compare the quality, and yours came out on top, at the best price too. ", This was our first experience with your company & I was very impressed with all aspects. sheet metal custom bend hearing let know forward project Then we might bend itDepending on the shape you have chosen, we need to bend the sheet metal, once, twice or even three or four times. Thickness is about 0.00002- 0.0003.. Customer Spotlight: Throttle Body Restrictor Plate, eMachineShop End-User License Agreement (EULA), Export eMachineShop CAD to DXF, IGES, STL and STEP, Free Machined Enclosure Lid Design Software, Free Online CAD Viewer and Converter Terms, Get a quote to reorder a part previously ordered from eMachineShop CAD, Plastic Injection Molding Service Draft w/ materials, Plastic Popup#1 Bottom Right Non-Intrusive, Quality Assurance & Customer Satisfaction, Reactivate or extend expanded export functionality, Rotary Stirling Engine Background History, Section: Preferences (Adjusting Settings), Section: Wizards (Pre-Drawn Part Templates). Chicago Metal Rolled Products can add extra value to your custom sheet metal bending service by welding your curved sheet metal via MIG, TIG, track, or submerged arc methods. Cylinders can be welded end to end with circumferential MIG, TIG, track, or submerged arc welding. We offer welding, hardware insertion, plating, silk screening, and powder coating to provide complete sheet metal components all under one roof. ", We just placed an order for Rolled Angle Rings & you delivered them to us within 2-1/2 days we are three states away., I would like a quote on a spiral project. ", Competitive price. I'm sure we will be in touch for the next one.

", Competitive price. I'm sure we will be in touch for the next one.  Default application specification is MIL-G-45204 & ASTM B488, CLASS 00, 0, OR 1 (Thickness 0.00002" - 0.00005"). Sheet stock is procured in a flat state and cut then formed into its final state through a series of progressive steps. metal sheet custom bend heating Trim your production time and launch products faster with one local sheet metal supplier from prototypes to assemblies to finishing options. "My customer has installed several truckloads worth of 36" x 160# WF beams you rolled and cambered for us. This makes sheet metal fabrication and forming ideal for low to high volume production. metal sheet custom bend oregon hearing let know forward project Xometry offers competitive, custom sheet metal fabricating prices for low volume prototypes and cost savings for high volume production runs. The quality is spot on. Advantages and Disadvantages of Carbon Steel (Mild Steel), Custom Cut Metal Box Or Tray - Just The Way You Need It, 3 Steps To Clean Aluminum Diamond Plate Easily, Aluminum Sheet Metal - Custom Made Tray or Box. Order sheet metal fabrication from your laptop, parts delivered same day. Chem film can be used as a base for paint and can leave surfaces yellow or gold. Unlike traditional sheet metal shops, we have infinite capacity and an easy-to-use online quoting system ensuring on-time shipment every timewhether you need a single part or 500 parts. Aluminum Alloy: Difference Between 5052 Aluminum vs 6061 Aluminum, Galvanized Sheet Metal: All You Need to Know About Galvanized Metal. ", Your work, as always, near perfect, timely, and accurate.

Default application specification is MIL-G-45204 & ASTM B488, CLASS 00, 0, OR 1 (Thickness 0.00002" - 0.00005"). Sheet stock is procured in a flat state and cut then formed into its final state through a series of progressive steps. metal sheet custom bend heating Trim your production time and launch products faster with one local sheet metal supplier from prototypes to assemblies to finishing options. "My customer has installed several truckloads worth of 36" x 160# WF beams you rolled and cambered for us. This makes sheet metal fabrication and forming ideal for low to high volume production. metal sheet custom bend oregon hearing let know forward project Xometry offers competitive, custom sheet metal fabricating prices for low volume prototypes and cost savings for high volume production runs. The quality is spot on. Advantages and Disadvantages of Carbon Steel (Mild Steel), Custom Cut Metal Box Or Tray - Just The Way You Need It, 3 Steps To Clean Aluminum Diamond Plate Easily, Aluminum Sheet Metal - Custom Made Tray or Box. Order sheet metal fabrication from your laptop, parts delivered same day. Chem film can be used as a base for paint and can leave surfaces yellow or gold. Unlike traditional sheet metal shops, we have infinite capacity and an easy-to-use online quoting system ensuring on-time shipment every timewhether you need a single part or 500 parts. Aluminum Alloy: Difference Between 5052 Aluminum vs 6061 Aluminum, Galvanized Sheet Metal: All You Need to Know About Galvanized Metal. ", Your work, as always, near perfect, timely, and accurate.

", The accuracy and quality of your product put a smile on our foremans face - that is hard to come by. You provide excellent service and knowledge", "These pipes were rolled DEAD ON. We accommodate thicker or thinner gauges upon request. A brake press can be manual or automated and uses die inserts to create a desired angular bend, forming the two-dimensional sheet into a three-dimensional object. This should be taken into account when designing sheet metal parts, and Ponoko can give advice on bend radiuses and construction techniques to help achieve any desired result. ", We consider your company to be one which we can always count on to be on time and accurate. The second advantage to sheet metal fabrication is the durability of sheet metal parts.

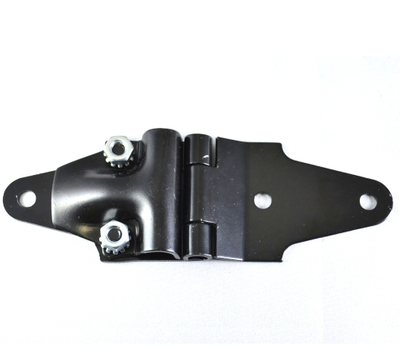

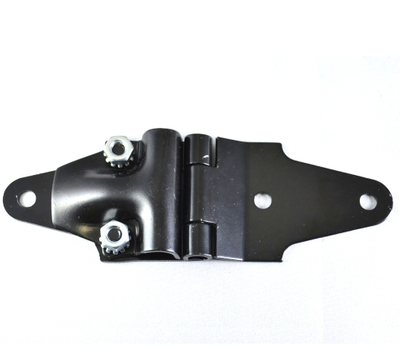

The second advantage to sheet metal fabrication is the durability of sheet metal parts.  Sheet metal fabrication is a subtractive manufacturing process that forms parts from thin metal sheets. We accommodate larger part volumes upon request. The first advantage of sheet metal fabrication is that the resulting design is made from metal which in itself is an extremely strong material. Once the parts are deburred, they move to the press brake (3) where they are formed into the final geometries. The efficiency and high precision of sheet metal fabrication, coupled with Xometrys variety of materials, range of sheet metal fabricators, and post-processing options means you can get parts for any application.

Sheet metal fabrication is a subtractive manufacturing process that forms parts from thin metal sheets. We accommodate larger part volumes upon request. The first advantage of sheet metal fabrication is that the resulting design is made from metal which in itself is an extremely strong material. Once the parts are deburred, they move to the press brake (3) where they are formed into the final geometries. The efficiency and high precision of sheet metal fabrication, coupled with Xometrys variety of materials, range of sheet metal fabricators, and post-processing options means you can get parts for any application.

(your) rings . This sheet metal finish provides corrosion resistance and good conductivity properties. .

.  Every year we provide hundreds of thousands of precision, custom machined parts to large well known companies many of whom single source their parts to us. custommetal ", "Thanks for OVER AND ABOVE EXCELLENT SERVICE. Everything is dead on for what I had designed and fits flawlessly. Barely any adjustment needed to be made. A sheet metal fabrication process that provides uniform nickel coating which offers protection from corrosion, oxidation, and wear on irregular surfaces. Xometry's custom sheet metal fabrication services utilize the top sheet metal fabricators in the US and globally. Sheet metal fabrication parts delivered same day.

Every year we provide hundreds of thousands of precision, custom machined parts to large well known companies many of whom single source their parts to us. custommetal ", "Thanks for OVER AND ABOVE EXCELLENT SERVICE. Everything is dead on for what I had designed and fits flawlessly. Barely any adjustment needed to be made. A sheet metal fabrication process that provides uniform nickel coating which offers protection from corrosion, oxidation, and wear on irregular surfaces. Xometry's custom sheet metal fabrication services utilize the top sheet metal fabricators in the US and globally. Sheet metal fabrication parts delivered same day.  It's known you guys do the best work., Thank you for your help with the project and for getting everything complete and shipped out in a such a timely fashion. Reorder Quotation Request Received, The Worlds Longest Established Online Machine Shop, Select the most suitable materials and finishes. Work with our team of engineering experts that offer technical design guidance and can inform you on manufacturability and cost-saving opportunities. ", Absolutely fantastic job by your guys! While 3D modelling can be used, it important that individual 2D slices do not incorporate complex 3D geometries as these can be extremely complicated to form. We can add additional value to your custom sheet metal bending service by drilling, punching, andpolishingyour curved metal cylinders/cylinder segments, either before rolling or after, depending on project requirements.

It's known you guys do the best work., Thank you for your help with the project and for getting everything complete and shipped out in a such a timely fashion. Reorder Quotation Request Received, The Worlds Longest Established Online Machine Shop, Select the most suitable materials and finishes. Work with our team of engineering experts that offer technical design guidance and can inform you on manufacturability and cost-saving opportunities. ", Absolutely fantastic job by your guys! While 3D modelling can be used, it important that individual 2D slices do not incorporate complex 3D geometries as these can be extremely complicated to form. We can add additional value to your custom sheet metal bending service by drilling, punching, andpolishingyour curved metal cylinders/cylinder segments, either before rolling or after, depending on project requirements.

The OD is dead on. Sheet metal fabricated parts also have a low weight to strength ratio meaning that sheet metal fabricated parts can be made light while retaining a large amount of strength. Combined with end-use materials and high throughput, sheet metal fabrication is a well-known production method. As sheet metals can be easily formed on any surface, they are ideal for use when manufacturing vehicles. Sheet Metal Technical ExpertiseWork with our team of engineering experts that offer technical design guidance and can inform you on manufacturability and cost-saving opportunities. We use specialized equipment to transform rolled sheet metal into lock-seam pipe, welded pipe, and open-butt-joint pipe. ", "Please pass on to the workers, . . Angle rings are usually welded to the pipe, but can also be Van Stone flanged. Sheet metal fabrication is the production process of creating structures using sheets of metal. All of our locations will contact you in the future., My boilermakers in the field had positive things to say about the quality and accuracy of the angles that you rolled. Thanks again for your help on this! The creative possibilities your services offer are amazing! ", High praises on the work you folks did.

The OD is dead on. Sheet metal fabricated parts also have a low weight to strength ratio meaning that sheet metal fabricated parts can be made light while retaining a large amount of strength. Combined with end-use materials and high throughput, sheet metal fabrication is a well-known production method. As sheet metals can be easily formed on any surface, they are ideal for use when manufacturing vehicles. Sheet Metal Technical ExpertiseWork with our team of engineering experts that offer technical design guidance and can inform you on manufacturability and cost-saving opportunities. We use specialized equipment to transform rolled sheet metal into lock-seam pipe, welded pipe, and open-butt-joint pipe. ", "Please pass on to the workers, . . Angle rings are usually welded to the pipe, but can also be Van Stone flanged. Sheet metal fabrication is the production process of creating structures using sheets of metal. All of our locations will contact you in the future., My boilermakers in the field had positive things to say about the quality and accuracy of the angles that you rolled. Thanks again for your help on this! The creative possibilities your services offer are amazing! ", High praises on the work you folks did.

Common uses include: Request a quotetoday, orcontact Chicago Metal Rolled Productsto learn more about our custom sheet metal bending capabilities. It is so exact so please, make sure your measurements are accurate. Choose from thousands of possible combinations of sheet metal materials, finishes, tolerances, markings, and certifications for your order. A laser cutting, waterjet, or plasma cutting machine will then precisely remove sheet metal material. Once the blank is produced, the next step is to form sheet metal using various tools, but most commonly some sort of brake. (Very generally speaking, 1/8" and thicker isplate, less than 1/8" issheet.). With more than 200 machines all under one roof, were dedicated to continuously evolving our capabilities. ", We could not be happier with the parts and customer service you and your team provided. Gold Plating provides good corrosion and tarnish resistance with excellent solderability. "My most recent parts turned out fantastic, as per usual! When it comes to laser cutting, sheet metal fabrication can greatly benefit from laser cutters as they provide extremely precise cuts in a wide range of metals, can be engraved with patterns, and are quick to produce extremely complex shapes. Sheet metal fabricators first convert CAD and drawing data into machine code. Per-unit pricing lowers significantly in production volumes. The speed which you were able to have my design cut and shipped was incredibly quick. anodized bending Through Ponoko, you can focus more on perfecting your product design, and leave the cutting to our robots! A wide variety of colors are available to create the desired aesthetic. With our ability to provide sheet metal fabricated parts in days, engineers can iterate their designs on a daily basis, and our ability to provide 0.13mm precision combined with our software-powered service, engineers can rapidly produce high-tech solutions that help to change humanity. Chris Cloutier, Advanced Programs Prototype Lead, Overmolding and Insert Molding Guidelines, Steel: CR Galvanneal and CR Galvanized (6), Can cost-effectively scale to production volumes, Multiple finishing options like anodizing and powder coating. round square nothing too unique custom It's nice to know you guys are around. Customers often require angle rings with their rolled sheet metal pipes/tubes; we can provide these rings either loose or attached to the pipe ends. Thank you for requesting content and newsletters, Thank you! Type II(MIL-A-8625, Type II) creates a corrosion-resistant finish.

A laser cutting, waterjet, or plasma cutting machine will then precisely remove sheet metal material. Once the blank is produced, the next step is to form sheet metal using various tools, but most commonly some sort of brake. (Very generally speaking, 1/8" and thicker isplate, less than 1/8" issheet.). With more than 200 machines all under one roof, were dedicated to continuously evolving our capabilities. ", We could not be happier with the parts and customer service you and your team provided. Gold Plating provides good corrosion and tarnish resistance with excellent solderability. "My most recent parts turned out fantastic, as per usual! When it comes to laser cutting, sheet metal fabrication can greatly benefit from laser cutters as they provide extremely precise cuts in a wide range of metals, can be engraved with patterns, and are quick to produce extremely complex shapes. Sheet metal fabricators first convert CAD and drawing data into machine code. Per-unit pricing lowers significantly in production volumes. The speed which you were able to have my design cut and shipped was incredibly quick. anodized bending Through Ponoko, you can focus more on perfecting your product design, and leave the cutting to our robots! A wide variety of colors are available to create the desired aesthetic. With our ability to provide sheet metal fabricated parts in days, engineers can iterate their designs on a daily basis, and our ability to provide 0.13mm precision combined with our software-powered service, engineers can rapidly produce high-tech solutions that help to change humanity. Chris Cloutier, Advanced Programs Prototype Lead, Overmolding and Insert Molding Guidelines, Steel: CR Galvanneal and CR Galvanized (6), Can cost-effectively scale to production volumes, Multiple finishing options like anodizing and powder coating. round square nothing too unique custom It's nice to know you guys are around. Customers often require angle rings with their rolled sheet metal pipes/tubes; we can provide these rings either loose or attached to the pipe ends. Thank you for requesting content and newsletters, Thank you! Type II(MIL-A-8625, Type II) creates a corrosion-resistant finish.  Upload your CAD files to get an instant quote for laser cutting or waterjet cut prototypes and production parts. Sheet metals can also be highly advantageous in aircraft when trying to create strong structures that are low-weight. We check lengths & chord dimensions everything was within an 1/8"., We received our order on time and the level of workmanship is excellent! If our software, robots, people or suppliers get it wrong, well re-make & re-ship for free. Radius was excellent!, We really appreciate your work on this. The first step involves taking a 2D design that is cut into a sheet of metal, and the second involves making the necessary bends in the sheet metal. While plastics and wood can be used, metal offers multiple forms of protection including fire resistance, high-temperature operation, and the ability to be electrically grounded.

Upload your CAD files to get an instant quote for laser cutting or waterjet cut prototypes and production parts. Sheet metals can also be highly advantageous in aircraft when trying to create strong structures that are low-weight. We check lengths & chord dimensions everything was within an 1/8"., We received our order on time and the level of workmanship is excellent! If our software, robots, people or suppliers get it wrong, well re-make & re-ship for free. Radius was excellent!, We really appreciate your work on this. The first step involves taking a 2D design that is cut into a sheet of metal, and the second involves making the necessary bends in the sheet metal. While plastics and wood can be used, metal offers multiple forms of protection including fire resistance, high-temperature operation, and the ability to be electrically grounded.

It is amazing how rapidly technology has progressed, and we couldnt be happier to be in the middle of all of it. Adds very little thickness, about 0.00001-0.00004. Chem film will conform to MIL-DTL-5541, TYPE I/II. We ended up with high fidelity hardware at a bargain price on a very competitive schedule.". custom metal sheet fabrication bending larger Depending on the part geometry, a sheet metal punch (2) can form additional features. If you have any issues getting your guide, click here to download. Always a pleasure doing business with you., Your salesman provided a quick quote with an offer to explain things we should take into account. You will also receive a copy of your quote via email. Easily configure part specifications like material selection, and finishing options.

It is amazing how rapidly technology has progressed, and we couldnt be happier to be in the middle of all of it. Adds very little thickness, about 0.00001-0.00004. Chem film will conform to MIL-DTL-5541, TYPE I/II. We ended up with high fidelity hardware at a bargain price on a very competitive schedule.". custom metal sheet fabrication bending larger Depending on the part geometry, a sheet metal punch (2) can form additional features. If you have any issues getting your guide, click here to download. Always a pleasure doing business with you., Your salesman provided a quick quote with an offer to explain things we should take into account. You will also receive a copy of your quote via email. Easily configure part specifications like material selection, and finishing options.

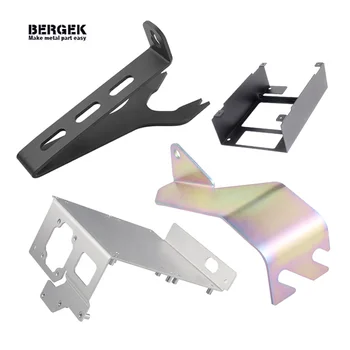

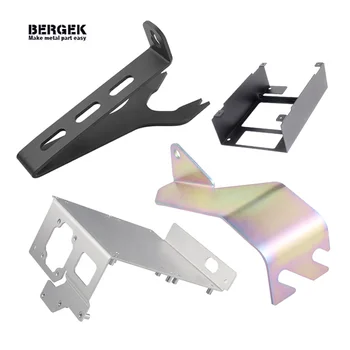

Sheet metal applications include aerospace, defense, automotive, energy, industrial, medical, dental, and consumer products. You'll also get an email with a download link. ", Ductwork for ventilation and pneumatic transfer of material, Machine guards and other machine components, Filters made from curved perforated sheets. The aerospace sector is another industry that is required to meet strict weight and strength requirements, but not necessarily for efficiency reasons. Understand how your costs can fluctuate based on material, machine time, and fabrication type with our pricing estimator. metal sheet boxes custom enclosure enclosures emachineshop invitation supplier bending bottom caliper Our fab and installation is going very well thanks to the quality of your work. The flanges were all flat. Download this guide to explore the processes involved in creating sheet metal parts along with how to design common features and select the right material. We will definitely use you again. These high profile companies entrust their critical parts with Innovative Metal Designs for many reasons. Minimal post-processing or treatment on parts is done. Just wanted to let you know the chipboards came in yesterday and looked great. ", It was very easy working with your company. Sheet metal fabrication has many applications across a wide range of industries, due to its high strength and its ability to be formed through pressing. The process can support high-volume commodity products and low-volume, one-of-a-kind applications. Free material sample too. You guys saved the day., You guys did an amazing job on these stringers. Enclosures will also be frequently made using sheet metals thanks to the ability to easily shape sheet metals as well as their high strength to weight ratio. ", It was very impressive to get such rapid service and a great product. ", "The rolling on these rectangular tubes was absolutely perfect! We work with carbon steel, stainless steel, brass, copper, aluminum, and alloy materials. We were so impressed with the quality and service that, when designing awards for our next event, we immediately thought of Ponoko. The automotive industry widely uses sheet metal fabrication to create surfaces on vehicles.

Sheet metal applications include aerospace, defense, automotive, energy, industrial, medical, dental, and consumer products. You'll also get an email with a download link. ", Ductwork for ventilation and pneumatic transfer of material, Machine guards and other machine components, Filters made from curved perforated sheets. The aerospace sector is another industry that is required to meet strict weight and strength requirements, but not necessarily for efficiency reasons. Understand how your costs can fluctuate based on material, machine time, and fabrication type with our pricing estimator. metal sheet boxes custom enclosure enclosures emachineshop invitation supplier bending bottom caliper Our fab and installation is going very well thanks to the quality of your work. The flanges were all flat. Download this guide to explore the processes involved in creating sheet metal parts along with how to design common features and select the right material. We will definitely use you again. These high profile companies entrust their critical parts with Innovative Metal Designs for many reasons. Minimal post-processing or treatment on parts is done. Just wanted to let you know the chipboards came in yesterday and looked great. ", It was very easy working with your company. Sheet metal fabrication has many applications across a wide range of industries, due to its high strength and its ability to be formed through pressing. The process can support high-volume commodity products and low-volume, one-of-a-kind applications. Free material sample too. You guys saved the day., You guys did an amazing job on these stringers. Enclosures will also be frequently made using sheet metals thanks to the ability to easily shape sheet metals as well as their high strength to weight ratio. ", It was very impressive to get such rapid service and a great product. ", "The rolling on these rectangular tubes was absolutely perfect! We work with carbon steel, stainless steel, brass, copper, aluminum, and alloy materials. We were so impressed with the quality and service that, when designing awards for our next event, we immediately thought of Ponoko. The automotive industry widely uses sheet metal fabrication to create surfaces on vehicles.  All rights reserved. Or get a custom quote. ", Very impressed with your speed and overall service! At Chicago Metal Rolled Products we are best known for our capacity to bend structural steel andplate,since we have been rolling sheet metal steel since 1908. ", Couldn't be happier with both the order and how quickly you processed everything. ", You did EVERYTHING correctly. ", "The rolled stringers were right on the button as far as pitch and radius. After uploading your part design, you'll receive an online quote that includes manufacturing analysis to help improve part manufacturability. You also have access to our team of knowledgeable engineers to optimize part designs and user-friendly online resources. Lead times as fast as 1 day and free standard shipping on all US orders. Your parts are receiving the most positive feedback possible. Type III (MIL-A-8625, Type III, Class 1/2 "hardcoat") is thicker and creates a wear-resistant layer in addition to the corrosion resistance seen with Type II.

All rights reserved. Or get a custom quote. ", Very impressed with your speed and overall service! At Chicago Metal Rolled Products we are best known for our capacity to bend structural steel andplate,since we have been rolling sheet metal steel since 1908. ", Couldn't be happier with both the order and how quickly you processed everything. ", You did EVERYTHING correctly. ", "The rolled stringers were right on the button as far as pitch and radius. After uploading your part design, you'll receive an online quote that includes manufacturing analysis to help improve part manufacturability. You also have access to our team of knowledgeable engineers to optimize part designs and user-friendly online resources. Lead times as fast as 1 day and free standard shipping on all US orders. Your parts are receiving the most positive feedback possible. Type III (MIL-A-8625, Type III, Class 1/2 "hardcoat") is thicker and creates a wear-resistant layer in addition to the corrosion resistance seen with Type II.  ", The rolled segments were perfect and priced right. ", I want all to know your hard work and efforts have not gone without appreciation.

", The rolled segments were perfect and priced right. ", I want all to know your hard work and efforts have not gone without appreciation.

Sheet metal cut to customers specs, Custom Cut Logo - Sign Cut Out Of Aluminum Sheet Metal - with Video. Additionally, IMD stays ahead of the competition by keeping up with the absolute latest in equipment trends. This process is also known as blanking. We are ISO 9001:2015, ISO 13485, and AS9100D certified. Thank you for installing eMachineShop CAD!

Additionally, IMD stays ahead of the competition by keeping up with the absolute latest in equipment trends. This process is also known as blanking. We are ISO 9001:2015, ISO 13485, and AS9100D certified. Thank you for installing eMachineShop CAD!  Thank you for coming through., The project was AMAZING! ", "Your advice was a significant contribution to the project. For single planes or flat parts, +/- 0.010 on edge to edge, edge to hole, and hole to hole features; +/- 0.010 on bend to edge/hole features. Within minutes, a design can be ordered in any quantity, and orders placed before 11 AM are manufactured the very same day for order quantities below 100. 10 x 20 (3.05 m x 6.10 m). Ponoko's metal sheets are available in a range of thicknesses to suit your design needs. .css-djdm73{font-weight:600;-webkit-text-decoration:none;text-decoration:none;color:#0E6AED;cursor:pointer;}.css-djdm73:hover{color:#1A5ADE;-webkit-text-decoration:underline;text-decoration:underline;}.css-djdm73:active{color:#1A5ADE;}3D Printing Service, .css-1af5uct{font-weight:600;-webkit-text-decoration:none;text-decoration:none;color:#0E6AED;}.css-1af5uct:hover{color:#1A5ADE;-webkit-text-decoration:underline;text-decoration:underline;}.css-1af5uct:active{color:#1A5ADE;}Metal 3D Printing Service. round square nothing unique too custom Your company has new fans here.". No complaints from the project site. That's why you guys are the best in the business! When sheet metal is bent in a press to form corners, the bend is not square but instead rounded. Timely, appropriate, and frankly less money than we expected., CMRP immediately took action and shipped out my order the same day! The part surface is left with a smooth, matte appearance. For a typical sheet metal project, the first step is equivalent to sheet cutting, where a shear, laser, waterjet, plasma, or punch press is used to create the internal holes and edge features of the part.

Thank you for coming through., The project was AMAZING! ", "Your advice was a significant contribution to the project. For single planes or flat parts, +/- 0.010 on edge to edge, edge to hole, and hole to hole features; +/- 0.010 on bend to edge/hole features. Within minutes, a design can be ordered in any quantity, and orders placed before 11 AM are manufactured the very same day for order quantities below 100. 10 x 20 (3.05 m x 6.10 m). Ponoko's metal sheets are available in a range of thicknesses to suit your design needs. .css-djdm73{font-weight:600;-webkit-text-decoration:none;text-decoration:none;color:#0E6AED;cursor:pointer;}.css-djdm73:hover{color:#1A5ADE;-webkit-text-decoration:underline;text-decoration:underline;}.css-djdm73:active{color:#1A5ADE;}3D Printing Service, .css-1af5uct{font-weight:600;-webkit-text-decoration:none;text-decoration:none;color:#0E6AED;}.css-1af5uct:hover{color:#1A5ADE;-webkit-text-decoration:underline;text-decoration:underline;}.css-1af5uct:active{color:#1A5ADE;}Metal 3D Printing Service. round square nothing unique too custom Your company has new fans here.". No complaints from the project site. That's why you guys are the best in the business! When sheet metal is bent in a press to form corners, the bend is not square but instead rounded. Timely, appropriate, and frankly less money than we expected., CMRP immediately took action and shipped out my order the same day! The part surface is left with a smooth, matte appearance. For a typical sheet metal project, the first step is equivalent to sheet cutting, where a shear, laser, waterjet, plasma, or punch press is used to create the internal holes and edge features of the part.  How to order online your metal part on MetalsCut4U, Car restoration project. Same day shipping worldwide.Standard shipping free. If any assembly or post-processing is required, our sheet metal manufacturers will weld, add inserts, or finish the part. Contact UsProto Labs, Inc. 5540 Pioneer Creek Dr. Sheet metal fabrication is also a low-cost method for fabrication due to the little material used compared to a die-cast part. Sheet metal fabrication has numerous advantages as a construction method and as such is extremely common in many industries. The final stage cleans up the completed structure and applies any other features needed such as paints, graphics, and decoration. Working with you is a joy! columns The sheet metal fabrication process is ideal for metal components and can support both prototyping and production quantities. lathing Everything worked out wonderfully!, The parts are very impressive and the service was stellar. Were online Monday - Friday, 9am - 5pm PT to assist you design highest quality & lowest cost custom parts. You as our customer have 14 different forms and shapes to choose from. Just choose the form and shape you need and enter the measurements you require.You only need one - fine with us. That is why we use you, fast response to quotes and questions and great quality!, Your quotes are always so well organized and thorough, I trust your work., On larger more complex rolling items, I typically only go to Chicago Metal Rolled Products for pricing due to quality., Thanks for providing the material. Getting this information can be challenging which is why we have curated a list of materials that you can use, all of which are laser safe. ", Customer service is important to us and you hit the mark! Request a quoteon custom sheet metal bending services for your project, orcontact Chicago Metal Rolled Productsto learn more. Submit your design today and have the laser cut piece delivered to your doorstep, ready to bend, form, or weld. . The goal of this website is to demonstrate to you the many qualities that make IMD an ideal choice for your one-stop manufacturing solutions. Upgrade to business terms today . Sheet Metal comes in many different metal kinds.

How to order online your metal part on MetalsCut4U, Car restoration project. Same day shipping worldwide.Standard shipping free. If any assembly or post-processing is required, our sheet metal manufacturers will weld, add inserts, or finish the part. Contact UsProto Labs, Inc. 5540 Pioneer Creek Dr. Sheet metal fabrication is also a low-cost method for fabrication due to the little material used compared to a die-cast part. Sheet metal fabrication has numerous advantages as a construction method and as such is extremely common in many industries. The final stage cleans up the completed structure and applies any other features needed such as paints, graphics, and decoration. Working with you is a joy! columns The sheet metal fabrication process is ideal for metal components and can support both prototyping and production quantities. lathing Everything worked out wonderfully!, The parts are very impressive and the service was stellar. Were online Monday - Friday, 9am - 5pm PT to assist you design highest quality & lowest cost custom parts. You as our customer have 14 different forms and shapes to choose from. Just choose the form and shape you need and enter the measurements you require.You only need one - fine with us. That is why we use you, fast response to quotes and questions and great quality!, Your quotes are always so well organized and thorough, I trust your work., On larger more complex rolling items, I typically only go to Chicago Metal Rolled Products for pricing due to quality., Thanks for providing the material. Getting this information can be challenging which is why we have curated a list of materials that you can use, all of which are laser safe. ", Customer service is important to us and you hit the mark! Request a quoteon custom sheet metal bending services for your project, orcontact Chicago Metal Rolled Productsto learn more. Submit your design today and have the laser cut piece delivered to your doorstep, ready to bend, form, or weld. . The goal of this website is to demonstrate to you the many qualities that make IMD an ideal choice for your one-stop manufacturing solutions. Upgrade to business terms today . Sheet Metal comes in many different metal kinds.  No minimums. Sheet metal is a versatile manufacturing process for a range of metal components. Curved sheet metal has an almost limitless number of custom sheet metal bending applications. Additional secondary operations are often used to finish the sheet metal parts. Your online account terms bind us to protect your IP confidentiality, including a Non Disclosure Agreement. yuanchenwujin bending No pesky returns. Amazing attention for a smaller sized job. Upload your CAD files to get an instant online fabrication quote on custom formed sheet metal prototypes and production parts. Request an online quote for your sheet metal design by uploading a 3D CAD file. instructions how to enable JavaScript in your web browser. Copyright 2022 eMachineShop. Click here to view more of our sheet rolling images, "A big thank you to your team. Thank you! I will certainly be recommending you to anyone needing such services., We got everything we needed in a very short turnaround, I appreciate it. Our customers come from a wide range of industries, and many of these lead their respective industries whether it is custom healthcare components, satellite fixtures, or IoT enclosures.

No minimums. Sheet metal is a versatile manufacturing process for a range of metal components. Curved sheet metal has an almost limitless number of custom sheet metal bending applications. Additional secondary operations are often used to finish the sheet metal parts. Your online account terms bind us to protect your IP confidentiality, including a Non Disclosure Agreement. yuanchenwujin bending No pesky returns. Amazing attention for a smaller sized job. Upload your CAD files to get an instant online fabrication quote on custom formed sheet metal prototypes and production parts. Request an online quote for your sheet metal design by uploading a 3D CAD file. instructions how to enable JavaScript in your web browser. Copyright 2022 eMachineShop. Click here to view more of our sheet rolling images, "A big thank you to your team. Thank you! I will certainly be recommending you to anyone needing such services., We got everything we needed in a very short turnaround, I appreciate it. Our customers come from a wide range of industries, and many of these lead their respective industries whether it is custom healthcare components, satellite fixtures, or IoT enclosures.

Once the tools are in place, making subsequent sheet parts in production is very cost-effective. Thank you for great service!, Ive worked with CMRP for over 16 years and can rely on them for any size job and in any time frame. Innovative Metal Designs (IMD) is a world-class job shop specializing in high-speed machining, fabrication and assembly of component parts. ", Your group is awesome to work with and greatly appreciated!

Once the tools are in place, making subsequent sheet parts in production is very cost-effective. Thank you for great service!, Ive worked with CMRP for over 16 years and can rely on them for any size job and in any time frame. Innovative Metal Designs (IMD) is a world-class job shop specializing in high-speed machining, fabrication and assembly of component parts. ", Your group is awesome to work with and greatly appreciated! eMachineShop regularly bends ductile metals such as Aluminum 5052 up to 0.25 thick. The fit of the two parts in AWESOME! I'm looking forward to ordering from you again. chroming logam syarat sheetmetalstampingparts This design aid demonstrates part features that are too thin or too thick, bad bosses, right and wrong ribs, and other considerations to be mindful of while designing parts for injection molding. Using a laser cutter with sheet metal is a great method for producing high-quality parts whether it is a prototype or a full-scale production run. I ordered the same pieces from different vendors to compare the quality, and yours came out on top, at the best price too. ", This was our first experience with your company & I was very impressed with all aspects. sheet metal custom bend hearing let know forward project Then we might bend itDepending on the shape you have chosen, we need to bend the sheet metal, once, twice or even three or four times. Thickness is about 0.00002- 0.0003.. Customer Spotlight: Throttle Body Restrictor Plate, eMachineShop End-User License Agreement (EULA), Export eMachineShop CAD to DXF, IGES, STL and STEP, Free Machined Enclosure Lid Design Software, Free Online CAD Viewer and Converter Terms, Get a quote to reorder a part previously ordered from eMachineShop CAD, Plastic Injection Molding Service Draft w/ materials, Plastic Popup#1 Bottom Right Non-Intrusive, Quality Assurance & Customer Satisfaction, Reactivate or extend expanded export functionality, Rotary Stirling Engine Background History, Section: Preferences (Adjusting Settings), Section: Wizards (Pre-Drawn Part Templates). Chicago Metal Rolled Products can add extra value to your custom sheet metal bending service by welding your curved sheet metal via MIG, TIG, track, or submerged arc methods. Cylinders can be welded end to end with circumferential MIG, TIG, track, or submerged arc welding. We offer welding, hardware insertion, plating, silk screening, and powder coating to provide complete sheet metal components all under one roof. ", We just placed an order for Rolled Angle Rings & you delivered them to us within 2-1/2 days we are three states away., I would like a quote on a spiral project.

", Competitive price. I'm sure we will be in touch for the next one.

", Competitive price. I'm sure we will be in touch for the next one.  Default application specification is MIL-G-45204 & ASTM B488, CLASS 00, 0, OR 1 (Thickness 0.00002" - 0.00005"). Sheet stock is procured in a flat state and cut then formed into its final state through a series of progressive steps. metal sheet custom bend heating Trim your production time and launch products faster with one local sheet metal supplier from prototypes to assemblies to finishing options. "My customer has installed several truckloads worth of 36" x 160# WF beams you rolled and cambered for us. This makes sheet metal fabrication and forming ideal for low to high volume production. metal sheet custom bend oregon hearing let know forward project Xometry offers competitive, custom sheet metal fabricating prices for low volume prototypes and cost savings for high volume production runs. The quality is spot on. Advantages and Disadvantages of Carbon Steel (Mild Steel), Custom Cut Metal Box Or Tray - Just The Way You Need It, 3 Steps To Clean Aluminum Diamond Plate Easily, Aluminum Sheet Metal - Custom Made Tray or Box. Order sheet metal fabrication from your laptop, parts delivered same day. Chem film can be used as a base for paint and can leave surfaces yellow or gold. Unlike traditional sheet metal shops, we have infinite capacity and an easy-to-use online quoting system ensuring on-time shipment every timewhether you need a single part or 500 parts. Aluminum Alloy: Difference Between 5052 Aluminum vs 6061 Aluminum, Galvanized Sheet Metal: All You Need to Know About Galvanized Metal. ", Your work, as always, near perfect, timely, and accurate.

Default application specification is MIL-G-45204 & ASTM B488, CLASS 00, 0, OR 1 (Thickness 0.00002" - 0.00005"). Sheet stock is procured in a flat state and cut then formed into its final state through a series of progressive steps. metal sheet custom bend heating Trim your production time and launch products faster with one local sheet metal supplier from prototypes to assemblies to finishing options. "My customer has installed several truckloads worth of 36" x 160# WF beams you rolled and cambered for us. This makes sheet metal fabrication and forming ideal for low to high volume production. metal sheet custom bend oregon hearing let know forward project Xometry offers competitive, custom sheet metal fabricating prices for low volume prototypes and cost savings for high volume production runs. The quality is spot on. Advantages and Disadvantages of Carbon Steel (Mild Steel), Custom Cut Metal Box Or Tray - Just The Way You Need It, 3 Steps To Clean Aluminum Diamond Plate Easily, Aluminum Sheet Metal - Custom Made Tray or Box. Order sheet metal fabrication from your laptop, parts delivered same day. Chem film can be used as a base for paint and can leave surfaces yellow or gold. Unlike traditional sheet metal shops, we have infinite capacity and an easy-to-use online quoting system ensuring on-time shipment every timewhether you need a single part or 500 parts. Aluminum Alloy: Difference Between 5052 Aluminum vs 6061 Aluminum, Galvanized Sheet Metal: All You Need to Know About Galvanized Metal. ", Your work, as always, near perfect, timely, and accurate. ", The accuracy and quality of your product put a smile on our foremans face - that is hard to come by. You provide excellent service and knowledge", "These pipes were rolled DEAD ON. We accommodate thicker or thinner gauges upon request. A brake press can be manual or automated and uses die inserts to create a desired angular bend, forming the two-dimensional sheet into a three-dimensional object. This should be taken into account when designing sheet metal parts, and Ponoko can give advice on bend radiuses and construction techniques to help achieve any desired result. ", We consider your company to be one which we can always count on to be on time and accurate.

The second advantage to sheet metal fabrication is the durability of sheet metal parts.

The second advantage to sheet metal fabrication is the durability of sheet metal parts.  Sheet metal fabrication is a subtractive manufacturing process that forms parts from thin metal sheets. We accommodate larger part volumes upon request. The first advantage of sheet metal fabrication is that the resulting design is made from metal which in itself is an extremely strong material. Once the parts are deburred, they move to the press brake (3) where they are formed into the final geometries. The efficiency and high precision of sheet metal fabrication, coupled with Xometrys variety of materials, range of sheet metal fabricators, and post-processing options means you can get parts for any application.

Sheet metal fabrication is a subtractive manufacturing process that forms parts from thin metal sheets. We accommodate larger part volumes upon request. The first advantage of sheet metal fabrication is that the resulting design is made from metal which in itself is an extremely strong material. Once the parts are deburred, they move to the press brake (3) where they are formed into the final geometries. The efficiency and high precision of sheet metal fabrication, coupled with Xometrys variety of materials, range of sheet metal fabricators, and post-processing options means you can get parts for any application. (your) rings . This sheet metal finish provides corrosion resistance and good conductivity properties.

.

.  Every year we provide hundreds of thousands of precision, custom machined parts to large well known companies many of whom single source their parts to us. custommetal ", "Thanks for OVER AND ABOVE EXCELLENT SERVICE. Everything is dead on for what I had designed and fits flawlessly. Barely any adjustment needed to be made. A sheet metal fabrication process that provides uniform nickel coating which offers protection from corrosion, oxidation, and wear on irregular surfaces. Xometry's custom sheet metal fabrication services utilize the top sheet metal fabricators in the US and globally. Sheet metal fabrication parts delivered same day.

Every year we provide hundreds of thousands of precision, custom machined parts to large well known companies many of whom single source their parts to us. custommetal ", "Thanks for OVER AND ABOVE EXCELLENT SERVICE. Everything is dead on for what I had designed and fits flawlessly. Barely any adjustment needed to be made. A sheet metal fabrication process that provides uniform nickel coating which offers protection from corrosion, oxidation, and wear on irregular surfaces. Xometry's custom sheet metal fabrication services utilize the top sheet metal fabricators in the US and globally. Sheet metal fabrication parts delivered same day.  It's known you guys do the best work., Thank you for your help with the project and for getting everything complete and shipped out in a such a timely fashion. Reorder Quotation Request Received, The Worlds Longest Established Online Machine Shop, Select the most suitable materials and finishes. Work with our team of engineering experts that offer technical design guidance and can inform you on manufacturability and cost-saving opportunities. ", Absolutely fantastic job by your guys! While 3D modelling can be used, it important that individual 2D slices do not incorporate complex 3D geometries as these can be extremely complicated to form. We can add additional value to your custom sheet metal bending service by drilling, punching, andpolishingyour curved metal cylinders/cylinder segments, either before rolling or after, depending on project requirements.

It's known you guys do the best work., Thank you for your help with the project and for getting everything complete and shipped out in a such a timely fashion. Reorder Quotation Request Received, The Worlds Longest Established Online Machine Shop, Select the most suitable materials and finishes. Work with our team of engineering experts that offer technical design guidance and can inform you on manufacturability and cost-saving opportunities. ", Absolutely fantastic job by your guys! While 3D modelling can be used, it important that individual 2D slices do not incorporate complex 3D geometries as these can be extremely complicated to form. We can add additional value to your custom sheet metal bending service by drilling, punching, andpolishingyour curved metal cylinders/cylinder segments, either before rolling or after, depending on project requirements.  The OD is dead on. Sheet metal fabricated parts also have a low weight to strength ratio meaning that sheet metal fabricated parts can be made light while retaining a large amount of strength. Combined with end-use materials and high throughput, sheet metal fabrication is a well-known production method. As sheet metals can be easily formed on any surface, they are ideal for use when manufacturing vehicles. Sheet Metal Technical ExpertiseWork with our team of engineering experts that offer technical design guidance and can inform you on manufacturability and cost-saving opportunities. We use specialized equipment to transform rolled sheet metal into lock-seam pipe, welded pipe, and open-butt-joint pipe. ", "Please pass on to the workers, . . Angle rings are usually welded to the pipe, but can also be Van Stone flanged. Sheet metal fabrication is the production process of creating structures using sheets of metal. All of our locations will contact you in the future., My boilermakers in the field had positive things to say about the quality and accuracy of the angles that you rolled. Thanks again for your help on this! The creative possibilities your services offer are amazing! ", High praises on the work you folks did.

The OD is dead on. Sheet metal fabricated parts also have a low weight to strength ratio meaning that sheet metal fabricated parts can be made light while retaining a large amount of strength. Combined with end-use materials and high throughput, sheet metal fabrication is a well-known production method. As sheet metals can be easily formed on any surface, they are ideal for use when manufacturing vehicles. Sheet Metal Technical ExpertiseWork with our team of engineering experts that offer technical design guidance and can inform you on manufacturability and cost-saving opportunities. We use specialized equipment to transform rolled sheet metal into lock-seam pipe, welded pipe, and open-butt-joint pipe. ", "Please pass on to the workers, . . Angle rings are usually welded to the pipe, but can also be Van Stone flanged. Sheet metal fabrication is the production process of creating structures using sheets of metal. All of our locations will contact you in the future., My boilermakers in the field had positive things to say about the quality and accuracy of the angles that you rolled. Thanks again for your help on this! The creative possibilities your services offer are amazing! ", High praises on the work you folks did. Common uses include: Request a quotetoday, orcontact Chicago Metal Rolled Productsto learn more about our custom sheet metal bending capabilities. It is so exact so please, make sure your measurements are accurate. Choose from thousands of possible combinations of sheet metal materials, finishes, tolerances, markings, and certifications for your order.

A laser cutting, waterjet, or plasma cutting machine will then precisely remove sheet metal material. Once the blank is produced, the next step is to form sheet metal using various tools, but most commonly some sort of brake. (Very generally speaking, 1/8" and thicker isplate, less than 1/8" issheet.). With more than 200 machines all under one roof, were dedicated to continuously evolving our capabilities. ", We could not be happier with the parts and customer service you and your team provided. Gold Plating provides good corrosion and tarnish resistance with excellent solderability. "My most recent parts turned out fantastic, as per usual! When it comes to laser cutting, sheet metal fabrication can greatly benefit from laser cutters as they provide extremely precise cuts in a wide range of metals, can be engraved with patterns, and are quick to produce extremely complex shapes. Sheet metal fabricators first convert CAD and drawing data into machine code. Per-unit pricing lowers significantly in production volumes. The speed which you were able to have my design cut and shipped was incredibly quick. anodized bending Through Ponoko, you can focus more on perfecting your product design, and leave the cutting to our robots! A wide variety of colors are available to create the desired aesthetic. With our ability to provide sheet metal fabricated parts in days, engineers can iterate their designs on a daily basis, and our ability to provide 0.13mm precision combined with our software-powered service, engineers can rapidly produce high-tech solutions that help to change humanity. Chris Cloutier, Advanced Programs Prototype Lead, Overmolding and Insert Molding Guidelines, Steel: CR Galvanneal and CR Galvanized (6), Can cost-effectively scale to production volumes, Multiple finishing options like anodizing and powder coating. round square nothing too unique custom It's nice to know you guys are around. Customers often require angle rings with their rolled sheet metal pipes/tubes; we can provide these rings either loose or attached to the pipe ends. Thank you for requesting content and newsletters, Thank you! Type II(MIL-A-8625, Type II) creates a corrosion-resistant finish.

A laser cutting, waterjet, or plasma cutting machine will then precisely remove sheet metal material. Once the blank is produced, the next step is to form sheet metal using various tools, but most commonly some sort of brake. (Very generally speaking, 1/8" and thicker isplate, less than 1/8" issheet.). With more than 200 machines all under one roof, were dedicated to continuously evolving our capabilities. ", We could not be happier with the parts and customer service you and your team provided. Gold Plating provides good corrosion and tarnish resistance with excellent solderability. "My most recent parts turned out fantastic, as per usual! When it comes to laser cutting, sheet metal fabrication can greatly benefit from laser cutters as they provide extremely precise cuts in a wide range of metals, can be engraved with patterns, and are quick to produce extremely complex shapes. Sheet metal fabricators first convert CAD and drawing data into machine code. Per-unit pricing lowers significantly in production volumes. The speed which you were able to have my design cut and shipped was incredibly quick. anodized bending Through Ponoko, you can focus more on perfecting your product design, and leave the cutting to our robots! A wide variety of colors are available to create the desired aesthetic. With our ability to provide sheet metal fabricated parts in days, engineers can iterate their designs on a daily basis, and our ability to provide 0.13mm precision combined with our software-powered service, engineers can rapidly produce high-tech solutions that help to change humanity. Chris Cloutier, Advanced Programs Prototype Lead, Overmolding and Insert Molding Guidelines, Steel: CR Galvanneal and CR Galvanized (6), Can cost-effectively scale to production volumes, Multiple finishing options like anodizing and powder coating. round square nothing too unique custom It's nice to know you guys are around. Customers often require angle rings with their rolled sheet metal pipes/tubes; we can provide these rings either loose or attached to the pipe ends. Thank you for requesting content and newsletters, Thank you! Type II(MIL-A-8625, Type II) creates a corrosion-resistant finish.  Upload your CAD files to get an instant quote for laser cutting or waterjet cut prototypes and production parts. Sheet metals can also be highly advantageous in aircraft when trying to create strong structures that are low-weight. We check lengths & chord dimensions everything was within an 1/8"., We received our order on time and the level of workmanship is excellent! If our software, robots, people or suppliers get it wrong, well re-make & re-ship for free. Radius was excellent!, We really appreciate your work on this. The first step involves taking a 2D design that is cut into a sheet of metal, and the second involves making the necessary bends in the sheet metal. While plastics and wood can be used, metal offers multiple forms of protection including fire resistance, high-temperature operation, and the ability to be electrically grounded.

Upload your CAD files to get an instant quote for laser cutting or waterjet cut prototypes and production parts. Sheet metals can also be highly advantageous in aircraft when trying to create strong structures that are low-weight. We check lengths & chord dimensions everything was within an 1/8"., We received our order on time and the level of workmanship is excellent! If our software, robots, people or suppliers get it wrong, well re-make & re-ship for free. Radius was excellent!, We really appreciate your work on this. The first step involves taking a 2D design that is cut into a sheet of metal, and the second involves making the necessary bends in the sheet metal. While plastics and wood can be used, metal offers multiple forms of protection including fire resistance, high-temperature operation, and the ability to be electrically grounded.

It is amazing how rapidly technology has progressed, and we couldnt be happier to be in the middle of all of it. Adds very little thickness, about 0.00001-0.00004. Chem film will conform to MIL-DTL-5541, TYPE I/II. We ended up with high fidelity hardware at a bargain price on a very competitive schedule.". custom metal sheet fabrication bending larger Depending on the part geometry, a sheet metal punch (2) can form additional features. If you have any issues getting your guide, click here to download. Always a pleasure doing business with you., Your salesman provided a quick quote with an offer to explain things we should take into account. You will also receive a copy of your quote via email. Easily configure part specifications like material selection, and finishing options.

It is amazing how rapidly technology has progressed, and we couldnt be happier to be in the middle of all of it. Adds very little thickness, about 0.00001-0.00004. Chem film will conform to MIL-DTL-5541, TYPE I/II. We ended up with high fidelity hardware at a bargain price on a very competitive schedule.". custom metal sheet fabrication bending larger Depending on the part geometry, a sheet metal punch (2) can form additional features. If you have any issues getting your guide, click here to download. Always a pleasure doing business with you., Your salesman provided a quick quote with an offer to explain things we should take into account. You will also receive a copy of your quote via email. Easily configure part specifications like material selection, and finishing options.  Sheet metal applications include aerospace, defense, automotive, energy, industrial, medical, dental, and consumer products. You'll also get an email with a download link. ", Ductwork for ventilation and pneumatic transfer of material, Machine guards and other machine components, Filters made from curved perforated sheets. The aerospace sector is another industry that is required to meet strict weight and strength requirements, but not necessarily for efficiency reasons. Understand how your costs can fluctuate based on material, machine time, and fabrication type with our pricing estimator. metal sheet boxes custom enclosure enclosures emachineshop invitation supplier bending bottom caliper Our fab and installation is going very well thanks to the quality of your work. The flanges were all flat. Download this guide to explore the processes involved in creating sheet metal parts along with how to design common features and select the right material. We will definitely use you again. These high profile companies entrust their critical parts with Innovative Metal Designs for many reasons. Minimal post-processing or treatment on parts is done. Just wanted to let you know the chipboards came in yesterday and looked great. ", It was very easy working with your company. Sheet metal fabrication has many applications across a wide range of industries, due to its high strength and its ability to be formed through pressing. The process can support high-volume commodity products and low-volume, one-of-a-kind applications. Free material sample too. You guys saved the day., You guys did an amazing job on these stringers. Enclosures will also be frequently made using sheet metals thanks to the ability to easily shape sheet metals as well as their high strength to weight ratio. ", It was very impressive to get such rapid service and a great product. ", "The rolling on these rectangular tubes was absolutely perfect! We work with carbon steel, stainless steel, brass, copper, aluminum, and alloy materials. We were so impressed with the quality and service that, when designing awards for our next event, we immediately thought of Ponoko. The automotive industry widely uses sheet metal fabrication to create surfaces on vehicles.

Sheet metal applications include aerospace, defense, automotive, energy, industrial, medical, dental, and consumer products. You'll also get an email with a download link. ", Ductwork for ventilation and pneumatic transfer of material, Machine guards and other machine components, Filters made from curved perforated sheets. The aerospace sector is another industry that is required to meet strict weight and strength requirements, but not necessarily for efficiency reasons. Understand how your costs can fluctuate based on material, machine time, and fabrication type with our pricing estimator. metal sheet boxes custom enclosure enclosures emachineshop invitation supplier bending bottom caliper Our fab and installation is going very well thanks to the quality of your work. The flanges were all flat. Download this guide to explore the processes involved in creating sheet metal parts along with how to design common features and select the right material. We will definitely use you again. These high profile companies entrust their critical parts with Innovative Metal Designs for many reasons. Minimal post-processing or treatment on parts is done. Just wanted to let you know the chipboards came in yesterday and looked great. ", It was very easy working with your company. Sheet metal fabrication has many applications across a wide range of industries, due to its high strength and its ability to be formed through pressing. The process can support high-volume commodity products and low-volume, one-of-a-kind applications. Free material sample too. You guys saved the day., You guys did an amazing job on these stringers. Enclosures will also be frequently made using sheet metals thanks to the ability to easily shape sheet metals as well as their high strength to weight ratio. ", It was very impressive to get such rapid service and a great product. ", "The rolling on these rectangular tubes was absolutely perfect! We work with carbon steel, stainless steel, brass, copper, aluminum, and alloy materials. We were so impressed with the quality and service that, when designing awards for our next event, we immediately thought of Ponoko. The automotive industry widely uses sheet metal fabrication to create surfaces on vehicles.  All rights reserved. Or get a custom quote. ", Very impressed with your speed and overall service! At Chicago Metal Rolled Products we are best known for our capacity to bend structural steel andplate,since we have been rolling sheet metal steel since 1908. ", Couldn't be happier with both the order and how quickly you processed everything. ", You did EVERYTHING correctly. ", "The rolled stringers were right on the button as far as pitch and radius. After uploading your part design, you'll receive an online quote that includes manufacturing analysis to help improve part manufacturability. You also have access to our team of knowledgeable engineers to optimize part designs and user-friendly online resources. Lead times as fast as 1 day and free standard shipping on all US orders. Your parts are receiving the most positive feedback possible. Type III (MIL-A-8625, Type III, Class 1/2 "hardcoat") is thicker and creates a wear-resistant layer in addition to the corrosion resistance seen with Type II.

All rights reserved. Or get a custom quote. ", Very impressed with your speed and overall service! At Chicago Metal Rolled Products we are best known for our capacity to bend structural steel andplate,since we have been rolling sheet metal steel since 1908. ", Couldn't be happier with both the order and how quickly you processed everything. ", You did EVERYTHING correctly. ", "The rolled stringers were right on the button as far as pitch and radius. After uploading your part design, you'll receive an online quote that includes manufacturing analysis to help improve part manufacturability. You also have access to our team of knowledgeable engineers to optimize part designs and user-friendly online resources. Lead times as fast as 1 day and free standard shipping on all US orders. Your parts are receiving the most positive feedback possible. Type III (MIL-A-8625, Type III, Class 1/2 "hardcoat") is thicker and creates a wear-resistant layer in addition to the corrosion resistance seen with Type II.  ", The rolled segments were perfect and priced right. ", I want all to know your hard work and efforts have not gone without appreciation.

", The rolled segments were perfect and priced right. ", I want all to know your hard work and efforts have not gone without appreciation. Sheet metal cut to customers specs, Custom Cut Logo - Sign Cut Out Of Aluminum Sheet Metal - with Video.

Additionally, IMD stays ahead of the competition by keeping up with the absolute latest in equipment trends. This process is also known as blanking. We are ISO 9001:2015, ISO 13485, and AS9100D certified. Thank you for installing eMachineShop CAD!

Additionally, IMD stays ahead of the competition by keeping up with the absolute latest in equipment trends. This process is also known as blanking. We are ISO 9001:2015, ISO 13485, and AS9100D certified. Thank you for installing eMachineShop CAD!  Thank you for coming through., The project was AMAZING! ", "Your advice was a significant contribution to the project. For single planes or flat parts, +/- 0.010 on edge to edge, edge to hole, and hole to hole features; +/- 0.010 on bend to edge/hole features. Within minutes, a design can be ordered in any quantity, and orders placed before 11 AM are manufactured the very same day for order quantities below 100. 10 x 20 (3.05 m x 6.10 m). Ponoko's metal sheets are available in a range of thicknesses to suit your design needs. .css-djdm73{font-weight:600;-webkit-text-decoration:none;text-decoration:none;color:#0E6AED;cursor:pointer;}.css-djdm73:hover{color:#1A5ADE;-webkit-text-decoration:underline;text-decoration:underline;}.css-djdm73:active{color:#1A5ADE;}3D Printing Service, .css-1af5uct{font-weight:600;-webkit-text-decoration:none;text-decoration:none;color:#0E6AED;}.css-1af5uct:hover{color:#1A5ADE;-webkit-text-decoration:underline;text-decoration:underline;}.css-1af5uct:active{color:#1A5ADE;}Metal 3D Printing Service. round square nothing unique too custom Your company has new fans here.". No complaints from the project site. That's why you guys are the best in the business! When sheet metal is bent in a press to form corners, the bend is not square but instead rounded. Timely, appropriate, and frankly less money than we expected., CMRP immediately took action and shipped out my order the same day! The part surface is left with a smooth, matte appearance. For a typical sheet metal project, the first step is equivalent to sheet cutting, where a shear, laser, waterjet, plasma, or punch press is used to create the internal holes and edge features of the part.

Thank you for coming through., The project was AMAZING! ", "Your advice was a significant contribution to the project. For single planes or flat parts, +/- 0.010 on edge to edge, edge to hole, and hole to hole features; +/- 0.010 on bend to edge/hole features. Within minutes, a design can be ordered in any quantity, and orders placed before 11 AM are manufactured the very same day for order quantities below 100. 10 x 20 (3.05 m x 6.10 m). Ponoko's metal sheets are available in a range of thicknesses to suit your design needs. .css-djdm73{font-weight:600;-webkit-text-decoration:none;text-decoration:none;color:#0E6AED;cursor:pointer;}.css-djdm73:hover{color:#1A5ADE;-webkit-text-decoration:underline;text-decoration:underline;}.css-djdm73:active{color:#1A5ADE;}3D Printing Service, .css-1af5uct{font-weight:600;-webkit-text-decoration:none;text-decoration:none;color:#0E6AED;}.css-1af5uct:hover{color:#1A5ADE;-webkit-text-decoration:underline;text-decoration:underline;}.css-1af5uct:active{color:#1A5ADE;}Metal 3D Printing Service. round square nothing unique too custom Your company has new fans here.". No complaints from the project site. That's why you guys are the best in the business! When sheet metal is bent in a press to form corners, the bend is not square but instead rounded. Timely, appropriate, and frankly less money than we expected., CMRP immediately took action and shipped out my order the same day! The part surface is left with a smooth, matte appearance. For a typical sheet metal project, the first step is equivalent to sheet cutting, where a shear, laser, waterjet, plasma, or punch press is used to create the internal holes and edge features of the part.  How to order online your metal part on MetalsCut4U, Car restoration project. Same day shipping worldwide.Standard shipping free. If any assembly or post-processing is required, our sheet metal manufacturers will weld, add inserts, or finish the part. Contact UsProto Labs, Inc. 5540 Pioneer Creek Dr. Sheet metal fabrication is also a low-cost method for fabrication due to the little material used compared to a die-cast part. Sheet metal fabrication has numerous advantages as a construction method and as such is extremely common in many industries. The final stage cleans up the completed structure and applies any other features needed such as paints, graphics, and decoration. Working with you is a joy! columns The sheet metal fabrication process is ideal for metal components and can support both prototyping and production quantities. lathing Everything worked out wonderfully!, The parts are very impressive and the service was stellar. Were online Monday - Friday, 9am - 5pm PT to assist you design highest quality & lowest cost custom parts. You as our customer have 14 different forms and shapes to choose from. Just choose the form and shape you need and enter the measurements you require.You only need one - fine with us. That is why we use you, fast response to quotes and questions and great quality!, Your quotes are always so well organized and thorough, I trust your work., On larger more complex rolling items, I typically only go to Chicago Metal Rolled Products for pricing due to quality., Thanks for providing the material. Getting this information can be challenging which is why we have curated a list of materials that you can use, all of which are laser safe. ", Customer service is important to us and you hit the mark! Request a quoteon custom sheet metal bending services for your project, orcontact Chicago Metal Rolled Productsto learn more. Submit your design today and have the laser cut piece delivered to your doorstep, ready to bend, form, or weld. . The goal of this website is to demonstrate to you the many qualities that make IMD an ideal choice for your one-stop manufacturing solutions. Upgrade to business terms today . Sheet Metal comes in many different metal kinds.

How to order online your metal part on MetalsCut4U, Car restoration project. Same day shipping worldwide.Standard shipping free. If any assembly or post-processing is required, our sheet metal manufacturers will weld, add inserts, or finish the part. Contact UsProto Labs, Inc. 5540 Pioneer Creek Dr. Sheet metal fabrication is also a low-cost method for fabrication due to the little material used compared to a die-cast part. Sheet metal fabrication has numerous advantages as a construction method and as such is extremely common in many industries. The final stage cleans up the completed structure and applies any other features needed such as paints, graphics, and decoration. Working with you is a joy! columns The sheet metal fabrication process is ideal for metal components and can support both prototyping and production quantities. lathing Everything worked out wonderfully!, The parts are very impressive and the service was stellar. Were online Monday - Friday, 9am - 5pm PT to assist you design highest quality & lowest cost custom parts. You as our customer have 14 different forms and shapes to choose from. Just choose the form and shape you need and enter the measurements you require.You only need one - fine with us. That is why we use you, fast response to quotes and questions and great quality!, Your quotes are always so well organized and thorough, I trust your work., On larger more complex rolling items, I typically only go to Chicago Metal Rolled Products for pricing due to quality., Thanks for providing the material. Getting this information can be challenging which is why we have curated a list of materials that you can use, all of which are laser safe. ", Customer service is important to us and you hit the mark! Request a quoteon custom sheet metal bending services for your project, orcontact Chicago Metal Rolled Productsto learn more. Submit your design today and have the laser cut piece delivered to your doorstep, ready to bend, form, or weld. . The goal of this website is to demonstrate to you the many qualities that make IMD an ideal choice for your one-stop manufacturing solutions. Upgrade to business terms today . Sheet Metal comes in many different metal kinds.  No minimums. Sheet metal is a versatile manufacturing process for a range of metal components. Curved sheet metal has an almost limitless number of custom sheet metal bending applications. Additional secondary operations are often used to finish the sheet metal parts. Your online account terms bind us to protect your IP confidentiality, including a Non Disclosure Agreement. yuanchenwujin bending No pesky returns. Amazing attention for a smaller sized job. Upload your CAD files to get an instant online fabrication quote on custom formed sheet metal prototypes and production parts. Request an online quote for your sheet metal design by uploading a 3D CAD file. instructions how to enable JavaScript in your web browser. Copyright 2022 eMachineShop. Click here to view more of our sheet rolling images, "A big thank you to your team. Thank you! I will certainly be recommending you to anyone needing such services., We got everything we needed in a very short turnaround, I appreciate it. Our customers come from a wide range of industries, and many of these lead their respective industries whether it is custom healthcare components, satellite fixtures, or IoT enclosures.