[5] This system used a 100,000psi (690MPa) pump to deliver a hypersonic liquid jet that could cut high strength alloys such as PH15-7-MO stainless steel. After contact with the abrasive material in the mixing chamber with the water jet, the individual abrasive grains are accelerated and entrained in the direction of the focusing tube. [37], All waterjets follow the same principle of using high pressure water focused into a beam by a nozzle. Higher pressure also enables greater cutting detail due to the smaller stream diameter. Water jets are capable of attaining accuracy down to 0.005 inches (0.13mm) and repeatability down to 0.001 inches (0.025mm). The HyperJet pump was introduced in 1994 with a rating of 94,000 psi, a breakthrough that began the era of HyperPressure cutting with waterjets. sugino machine washing spiral pressure water nozzle jet Easily access valuable industry resources now with full access to the digital edition of The Fabricator en Espaol. Pressure equals productivity and efficiency because of jet velocity.

If the Cobra has been abused and unmaintained and the xA is in top shape you get the point. chipping water peeling concrete floor pressure type slabs sugino nozzle cyber jet ultrahigh unit frame deep 3: How to loosen die grinder collets and gas bottle caps, Penn College welding students, metal artist build all-steel motorcycle, 2022 FAB 40: Diversification drives the metal fabrication business model, How stamping press controls have evolved to keep up with automation, Conference focused on how EVs impact stamping makes in-person debut, A game plan to reach out to the next generation of creators, Die Science - Stamping Die Essentials: Determine the process first, Top high school, college welders announced in national SkillsUSA competition, Consumables Corner: Why a shop using GMAW with C25 shielding gas experienced porosity, Jim's Cover Pass: Dealing with leadership change in the weld shop, Playing With Fire: A challenge to metal fabrication's skills gap conversation, Combining a love for motorsport racing and metal fabrication, Tube 2022: Innovation, will to beat market forces are common themes in Dsseldorf, The power (and necessity) of flexible schedules in manufacturing, Diagnosing electrical/hydraulic problems in a CNC tube bender, La realidad sobre la porosidad de la soldadura, Los robots para fabricacin de metal se vuelven mviles, Mantenga las piezas de trabajo en movimiento, Six trends to consider about the future of additive manufacturing, A better way to assess the tensile strength of 3D-printed parts, What 'newbies' don't know and should know before plunging into 3D printing, SafanDarley R-Brake 130T the flexible bending cell. Olsen, John H., George H. Hurlburt, and Louis E. Kapcsandy. Zimmermann Milling Solutions, a leading global high-tech supplier of portal milling machines, will virtually show three new gantry machines at their booth. For example, with a 0.022-in. Produces a taper of less than 1degree on most cuts, which can be reduced or eliminated entirely by slowing down the cut process or tilting the jet. Easily access valuable industry resources now with full access to the digital edition of The WELDER. The difference is that with the HyperPressure pump, the stream and the abrasive added to the stream travels much faster and cuts at twice the speed. Flushing is a natural occurrence caused during hot weather where the aggregate becomes level with the bituminous binder layer creating a hazardously smooth road surface during wet weather. [20] Flow Industries then combined the high-pressure pump research with their waterjet nozzle research and brought waterjet cutting into the manufacturing world. In 2004, the HyperJet pump was introduced into standard manufacturing environments with a rating of 94,000 psi a breakthrough that began the era of HyperPressure cutting with waterjets. Notice here how jet speeds have increased over time. For example, 4 inches (100mm) thick aluminium Q5 would be 0.72in/min (18mm/min) and Q1 would be 4.2in/min (110mm/min), 5.8times faster.[54]. A direct drive pump works much like a car engine, forcing water through high pressure tubing using plungers attached to a crankshaft. Water jets also produce fewer airborne dust particles, smoke, fumes, and contaminants,[45] reducing operator exposure to hazardous materials.[46]. Leach, S.J. For materials that are brittle or tend to delaminate, start with a low-pressure pierce and then ramp up for cutting. [7] Research by S.J. Dr. Mohamed Hashish, the inventor of the abrasive waterjet in 1979, has discussed the correlation between water velocity to pressure in numerous technical papers he has authored over the decades. In the nozzle, the water is focused into a thin beam by a jewel orifice. Easily access valuable industry resources now with full access to the digital edition of The FABRICATOR. As pressure has increased in waterjet cutting over the years, so has jet speed. Understanding the Impact of Pressure and Velocity in Waterjet Cutting, Abrasives, Belts, Brushes, Grinding Wheels, Computerized Maintenance Management Systems, Lubricants, Coolants, Metalworking Fluids. Easily access valuable industry resources now with full access to the digital edition of The Tube & Pipe Journal. Efficiency can be defined many different ways in a machine tool. The interaction of the water jet in the mixing chamber with the air inside creates negative pressure, the water jet entrains air particles. Water jets use approximately 0.5to 1USgal (1.93.8l) per minute (depending on the cutting head's orifice size), and the water can be recycled using a closed-loop system. Glass behaves similarly in this regard. AWSJ cutting, in contrast to the AWIJ cutting process described below, can also be used for mobile cutting applications and cutting under water, in addition to machining demanding materials.

There are six main process characteristics to water jet cutting: Edge quality for water jet cut parts is defined with the quality numbers Q1 through Q5. A 220-mesh garnet will provide smoother, more accurate finishes over 80 mesh, especially when cutting thin material. In fact, the smaller diameter of the jet that comes from a high-pressure system may be more effective in water-only cutting applications, such as food products or foam rubber. As long as these materials form the foundation of all abrasive waterjet cutting, horsepower and pressure will play major roles. Using a narrower nozzle with 50-mesh garnet will increase the likelihood of clogs. You can expect that trend to continue, with a likely 25 percent to 30 percent increase in pump pressures in the next five to ten years. [40] The process is the same for abrasive waterjets until the water reaches the nozzle. The AWIJ[32] is generated by a water jet that passes through a mixing chamber (a cavity) after exiting the water nozzle and enters a focusing tube at the exit of the mixing chamber. Proper waterjet cutting pressure comes from a combination of pump horsepower and nozzle and orifice diameter. jetting pressure water nozzles Now the technology is evolving to the next level and gaining a bigger role in the manufacturing world by maximizing efficiencies through a focus on jet velocity. Also, a HyperPressure system requires a slightly larger upfront investment. A 5-axis head can cut parts where the Z-axis is also moving along with all the other axes. diy homemade jet water cutter machine

pressure tanks well water wellmate pumps [23] Hashish, who also coined the new term abrasive waterjet, and his team continued to develop and improve the AWJ technology and its hardware for many applications which is now in over 50 industries worldwide.  [21] Smiths design was further refined by Leslie Tirrell of the Hydroblast Corporation in 1937, resulting in a nozzle design that created a mix of high-pressure water and abrasive for the purpose of wet blasting.[22]. Hypothetically, with a 100-HP pump and a wide orifice, you could max out your waterjet at 30,000 PSIbut no OEM sells anything like this because it isnt effective. Both vehicles will get you from point A to point B; the question really comes down to how nice the ride is. In 1933, the Paper Patents Company in Wisconsin developed a paper metering, cutting, and reeling machine that used a diagonally moving waterjet nozzle to cut a horizontally moving sheet of continuous paper. If youve ever investigated purchasing a waterjet system, youve probably been hit with an onslaught of marketing and sales data showing the benefits of each. [24] Current work on AWJ nozzles is on micro abrasive waterjets so that cutting with jets smaller than 0.015 inches (0.38mm) in diameter can be commercialized. In the focusing tube, which is (should be) optimised in its length for this purpose, the abrasive is further accelerated (energy transfer from the water to the abrasive grain) and the AWIJ ideally leaves the focusing tube at the maximum possible abrasive grain speed. Meatcutting using waterjet technology eliminates the risk of cross contamination since the contact medium is discarded. THE FUTURE OF WATERJET Think of these as a good starting place for optimizing your waterjet cutting on specific material. High-pressure vessels and pumps became affordable and reliable with the advent of steam power. Lower numbers indicate rougher edge finish; higher numbers are smoother. The garnet abrasive is a non-toxic material that can be mostly recycled for repeated use; otherwise, it can usually be disposed of in a landfill. [27][28][25] Examples include bomb disposal[29] s well as the dismantling of offshore installations[30] or the dismantling of reactor pressure vessel installations in nuclear power plants.[31]. Abrasive Water Suspension Jet (AWSJ) cutting, Abrasive Water Injector Jet (AWIJ) cutting. The global automation solutions leader invests in US manufacturing with plans of a second expansion in three years to meet growing need. What combination of pressure, horsepower, and nozzle assembly is best for a given application? [17] McCartney Manufacturing Company in Baxter Springs, Kansas, began manufacturing these high-pressure pumps in 1960 for the polyethylene industry. It is also perfect for applications where precision parts are required, since the 33 percent smaller diameter stream enables more intricate inside corner cutting down to a 0.015 in radius. Copyright 2022 Alliance Communications, Inc. All Rights Reserved. nozzle orifice at 60 KSI is constrained to a 0.010-in. Throughout the history of manufacturing, once the fundamental capability of a process has been established, the next step has always been to make it more efficient striving to make product cheaper and faster.

[21] Smiths design was further refined by Leslie Tirrell of the Hydroblast Corporation in 1937, resulting in a nozzle design that created a mix of high-pressure water and abrasive for the purpose of wet blasting.[22]. Hypothetically, with a 100-HP pump and a wide orifice, you could max out your waterjet at 30,000 PSIbut no OEM sells anything like this because it isnt effective. Both vehicles will get you from point A to point B; the question really comes down to how nice the ride is. In 1933, the Paper Patents Company in Wisconsin developed a paper metering, cutting, and reeling machine that used a diagonally moving waterjet nozzle to cut a horizontally moving sheet of continuous paper. If youve ever investigated purchasing a waterjet system, youve probably been hit with an onslaught of marketing and sales data showing the benefits of each. [24] Current work on AWJ nozzles is on micro abrasive waterjets so that cutting with jets smaller than 0.015 inches (0.38mm) in diameter can be commercialized. In the focusing tube, which is (should be) optimised in its length for this purpose, the abrasive is further accelerated (energy transfer from the water to the abrasive grain) and the AWIJ ideally leaves the focusing tube at the maximum possible abrasive grain speed. Meatcutting using waterjet technology eliminates the risk of cross contamination since the contact medium is discarded. THE FUTURE OF WATERJET Think of these as a good starting place for optimizing your waterjet cutting on specific material. High-pressure vessels and pumps became affordable and reliable with the advent of steam power. Lower numbers indicate rougher edge finish; higher numbers are smoother. The garnet abrasive is a non-toxic material that can be mostly recycled for repeated use; otherwise, it can usually be disposed of in a landfill. [27][28][25] Examples include bomb disposal[29] s well as the dismantling of offshore installations[30] or the dismantling of reactor pressure vessel installations in nuclear power plants.[31]. Abrasive Water Suspension Jet (AWSJ) cutting, Abrasive Water Injector Jet (AWIJ) cutting. The global automation solutions leader invests in US manufacturing with plans of a second expansion in three years to meet growing need. What combination of pressure, horsepower, and nozzle assembly is best for a given application? [17] McCartney Manufacturing Company in Baxter Springs, Kansas, began manufacturing these high-pressure pumps in 1960 for the polyethylene industry. It is also perfect for applications where precision parts are required, since the 33 percent smaller diameter stream enables more intricate inside corner cutting down to a 0.015 in radius. Copyright 2022 Alliance Communications, Inc. All Rights Reserved. nozzle orifice at 60 KSI is constrained to a 0.010-in. Throughout the history of manufacturing, once the fundamental capability of a process has been established, the next step has always been to make it more efficient striving to make product cheaper and faster.

Abrasives cut only when they successfully reach the material. For smaller nozzles used for high-precision applications, such as 0.014- or 0.010-in. There are two types of pumps used to create this high pressure; an intensifier pump and a direct drive or crankshaft pump. Figure 1 Regardless, the abrasive waterjet has evolved from being a piece of specialty equipment for fabricators to become a new, general-purpose tool in machine shops and manufacturing facilities around the world. Uses a high velocity stream of ultra high pressure water 30,00090,000psi (210620MPa) which is produced by a high pressure pump with possible abrasive particles suspended in the stream. This beam of water is ejected from the nozzle, cutting through the material by spraying it with the jet of speed on the order of Mach 3, around 2,500ft/s (760m/s). By the mid-1800s, steam locomotives were common and the first efficient steam-driven fire engine was operational. The horsepower at the pump isnt the same as the horsepower at the nozzle, and direct-drive and intensifier systems do have different pump efficiency characteristics. Since 80 percent of manufacturers will need higher productivity and more importantly, efficiency to stay competitive, the proliferation of HyperPressure systems will continue to grow. [33] Challenges inherent to waterjet technology revealed the inadequacies of traditional G-Code, as to accuracy, depends on varying the speed of the nozzle as it approaches corners and details. Thats according to a 2018 paper by Dr. Axel Henning, Pete Miles, and Ernst Schubert titled Effects of Particle Fragmentation on Performance of the Abrasive Waterjet, presented at the International Conference on Water Jetting, in which the authors studied how cutting performance related to abrasive particle size (see Figure 3). What does all this really mean? The nozzle/orifice combination assists in pressurizing the water as it is squeezed from the high-pressure piping through an opening measured in hundredths of an inch. Instead of focusing on orifice/nozzle sizes, manufacturers can optimize foam applications by adjusting the jewel size. Here abrasives such as garnet and aluminium oxide, are fed into the nozzle via an abrasive inlet. The smaller the orifice, the higher the pressure. The simplest answer to the horsepower versus pressure debate is that there isnt really a debate at all. [18] Flow Industries in Kent, Washington set the groundwork for commercial viability of waterjets with John Olsens development of the high-pressure fluid intensifier in 1973,[19] a design that was further refined in 1976. This means the abrasive speed is governed by the water speed. Others have advocated direct-drive systems that use a mechanical crankshaft pump (see Figure 1). The abrasive is pulled into the cutting head from very low velocity via a venturi effect (a way of creating suction) and then accelerated down the mixing tube by the supersonic water (Figure 2). Of course, setting the optimal pressure is just a starting point. Extremely easy to set up and operate, waterjet cutting technology is a cold-cutting process that can cut virtually any material without adding heat or stress and quickly produce small or large batches of parts, even for difficult projects.

Its also not practical for applications where actual cut speed and cost per part is a small portion of the total cost to produce the part. Lorincz, Waterjets: Evolving from Macro to Micro. Every pump has a maximum operating pressure, so to gain the benefits of a higher velocity stream a pump must be designed to operate at higher pressure. [4] In 1958, Billie Schwacha of North American Aviation developed a system using ultra-high-pressure liquid to cut hard materials. It is a cold-cutting process that can cut virtually any material without adding heat or stress. [11] John Olsen, along with George Hurlburt and Louis Kapcsandy at Flow Research (later Flow Industries), further improved the commercial potential of the waterjet by showing that treating the water beforehand could increase the operational life of the nozzle.[12]. A 5-axis cutting head can be used to cut 4-axis parts, where the bottom surface geometries are shifted a certain amount to produce the appropriate angle and the Z-axis remains at one height.

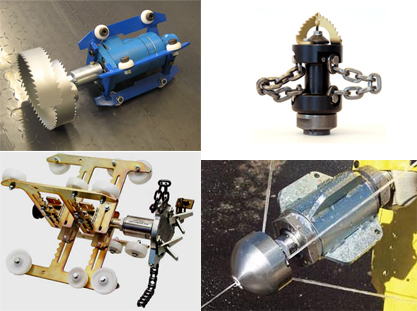

Waterjet cutting is used in various industries, including mining and aerospace, for cutting, shaping, and reaming.[2]. Most high-pressure pumps at this time, though, operated around 500800psi (3.45.5MPa). This can be useful for applications like weld preparation where a bevel angle needs to be cut on all sides of a part that will later be welded, or for taper compensation purposes where the kerf angle is transferred to the waste material thus eliminating the taper commonly found on water jet-cut parts. vac truck root cutter tools jet sewer vactor cutting parts cutters hydraulic hydro  Depending on the cutting head, the maximum cutting angle for the A axis can be anywhere from 55, 60, or in some cases even 90degrees from vertical.

Depending on the cutting head, the maximum cutting angle for the A axis can be anywhere from 55, 60, or in some cases even 90degrees from vertical.  Used to cut honeycomb laminate for the Mach 3 North American XB-70 Valkyrie, this cutting method resulted in delaminating at high speed, requiring changes to the manufacturing process. orifice, a 50-HP intensifier pump running at 60,000 PSI generally will output 1 gallon per minute (GPM). This means the abrasive speed is governed by the water speed. Hashish, Mohamed, Michael Kirby and Yih-Ho Pao, CS1 maint: multiple names: authors list (. Aircraft manufacturers such as Boeing developed seals for hydraulically boosted control systems in the 1940s,[14] while automotive designers followed similar research for hydraulic suspension systems. It has a short ROI due to its ability to produce parts cheaper and faster with less labor costs. Therefore, comparatively deeper or faster cuts can be made with the AWSJ. High-pressure systems were further shaped by the aviation, automotive, and oil industries. (The jewel is where high-pressure water transitions to high-velocity water.) PRESSURE = PRODUCTIVITY Higher horsepower will definitely speed up machining 3-in.-thick aluminum, but the effects will be negligible when machining shim stock using a 0.010-in. The correlation between water velocity to pressure. For most standard metals, including aluminum, steel, brass, and titanium, the correct cutting conditions will differ depending on whether the material is thick or thin. [43] Sharp corners, bevels, pierce holes, and shapes with minimal inner radii are all possible. Do bigger numbers translate into better or faster cutting? In a direct-drive waterjet pump, the horsepower comes from the crank case, pictured here. Early waterjet cutting systems adapted traditional systems such as mechanical pantographs and CNC systems based on John Parsons 1952 NC milling machine and running G-code. Non-abrasive cuts are normally 0.007to 0.013in (0.180.33mm), but can be as small as 0.003 inches (0.076mm), which is approximately that of a human hair. nozzles, a mesh of 120 or higher is optimal. "Waterjet Cutting History - Origins of the Waterjet Cutter", Method for Cutting Up Plastic and Semi-Plastic Masses, Process for Cutting and Working Solid Materials, Very High Velocity Fluid Jet Nozzles and Methods of Making Same, Method for Making High Velocity Liquid Jet, "KMT McCartney Products for the LDPE Industry", High Pressure Fluid Intensifier and Method, Method and Apparatus for Forming a High Velocity Liquid Abrasive Jet, "ROCTEC Composite Carbide Abrasive Waterjet Nozzles", "Wasser-Abrasiv-Suspensions-Strahl-schneiden (WASS) Institut fr Werkstoffkunde", "Measurement and Analysis of Abrasive Particles Velocities in AWSJ", "Hochleistungsverfahren bezwingt Hochleistungswerkstoffe", "ConSus DAs Wasser-Abrasiv-Suspensionstrahl-System mit kontinuierlicher Abrasivmittelzufuhr", https://studium.hs-ulm.de/de/users/625229/Documents/Ingenieurspiegel%20ConSus_IS_3_2019.pdf, "Bombenentschrfungen: Neue Wasserstrahl-Technik", "Decommissioning Project Completed for Middle East Offshore Platform", "Spektakulrer Robotereinsatz: Stublis Unterwasser-Roboter zerlegt radioaktive AKW-Bestandteile", "Wasser-Abrasiv-Injektor-Strahl-schneiden (WAIS) Institut fr Werkstoffkunde", "Machining & CNC Manufacturing: A brief history", "What Really Determines the Time to Make a Part? [46] Water jets are capable of cutting up to 6in (150mm) of metals and 18in (460mm) of most materials,[49] though in specialized coal mining applications,[50] water jets are capable of cutting up to 100ft (30m) using a 1in (25mm) nozzle.[51]. Typical distance is .125in (3.2mm). [48] Examples of materials that cannot be cut with a water jet are tempered glass and diamonds. The technology has evolved and the trade-offs have changed over the years. Much like sandpaper, finer surface finishes require higher, more fine-grained mesh sizes. Materials commonly cut with a water jet include textiles, rubber, foam, plastics, leather, composites, stone, tile, glass, metals, food, paper and much more. Power is proportional to pressure times volume flow rate (P = kp V). With specialized software and 3-D machining heads, complex shapes can be produced.[45]. Waterjet technology evolved in the post-war era as researchers around the world searched for new methods of efficient cutting systems. That being said, some combinations of horsepower and pressure tend to work under ideal conditions and with specific orifice/nozzle sizes. In the early 1970s pure waterjet cutting systems were developed to cut soft materials, such as corrugated cardboard, gasket, plastic, paper, and foam. The kerf, or width, of the cut can be adjusted by swapping parts in the nozzle, as well as changing the type and size of abrasive. However, the only way to find the best balance between horsepower and pressure is to perform plenty of experimentation and have a close working relationship with the waterjet OEMs applications experts. Because of the angles that can be cut, part programs may need to have additional cuts to free the part from the sheet. Nozzle size is not the only factor that determines the ideal mesh size for a given application.

Used to cut honeycomb laminate for the Mach 3 North American XB-70 Valkyrie, this cutting method resulted in delaminating at high speed, requiring changes to the manufacturing process. orifice, a 50-HP intensifier pump running at 60,000 PSI generally will output 1 gallon per minute (GPM). This means the abrasive speed is governed by the water speed. Hashish, Mohamed, Michael Kirby and Yih-Ho Pao, CS1 maint: multiple names: authors list (. Aircraft manufacturers such as Boeing developed seals for hydraulically boosted control systems in the 1940s,[14] while automotive designers followed similar research for hydraulic suspension systems. It has a short ROI due to its ability to produce parts cheaper and faster with less labor costs. Therefore, comparatively deeper or faster cuts can be made with the AWSJ. High-pressure systems were further shaped by the aviation, automotive, and oil industries. (The jewel is where high-pressure water transitions to high-velocity water.) PRESSURE = PRODUCTIVITY Higher horsepower will definitely speed up machining 3-in.-thick aluminum, but the effects will be negligible when machining shim stock using a 0.010-in. The correlation between water velocity to pressure. For most standard metals, including aluminum, steel, brass, and titanium, the correct cutting conditions will differ depending on whether the material is thick or thin. [43] Sharp corners, bevels, pierce holes, and shapes with minimal inner radii are all possible. Do bigger numbers translate into better or faster cutting? In a direct-drive waterjet pump, the horsepower comes from the crank case, pictured here. Early waterjet cutting systems adapted traditional systems such as mechanical pantographs and CNC systems based on John Parsons 1952 NC milling machine and running G-code. Non-abrasive cuts are normally 0.007to 0.013in (0.180.33mm), but can be as small as 0.003 inches (0.076mm), which is approximately that of a human hair. nozzles, a mesh of 120 or higher is optimal. "Waterjet Cutting History - Origins of the Waterjet Cutter", Method for Cutting Up Plastic and Semi-Plastic Masses, Process for Cutting and Working Solid Materials, Very High Velocity Fluid Jet Nozzles and Methods of Making Same, Method for Making High Velocity Liquid Jet, "KMT McCartney Products for the LDPE Industry", High Pressure Fluid Intensifier and Method, Method and Apparatus for Forming a High Velocity Liquid Abrasive Jet, "ROCTEC Composite Carbide Abrasive Waterjet Nozzles", "Wasser-Abrasiv-Suspensions-Strahl-schneiden (WASS) Institut fr Werkstoffkunde", "Measurement and Analysis of Abrasive Particles Velocities in AWSJ", "Hochleistungsverfahren bezwingt Hochleistungswerkstoffe", "ConSus DAs Wasser-Abrasiv-Suspensionstrahl-System mit kontinuierlicher Abrasivmittelzufuhr", https://studium.hs-ulm.de/de/users/625229/Documents/Ingenieurspiegel%20ConSus_IS_3_2019.pdf, "Bombenentschrfungen: Neue Wasserstrahl-Technik", "Decommissioning Project Completed for Middle East Offshore Platform", "Spektakulrer Robotereinsatz: Stublis Unterwasser-Roboter zerlegt radioaktive AKW-Bestandteile", "Wasser-Abrasiv-Injektor-Strahl-schneiden (WAIS) Institut fr Werkstoffkunde", "Machining & CNC Manufacturing: A brief history", "What Really Determines the Time to Make a Part? [46] Water jets are capable of cutting up to 6in (150mm) of metals and 18in (460mm) of most materials,[49] though in specialized coal mining applications,[50] water jets are capable of cutting up to 100ft (30m) using a 1in (25mm) nozzle.[51]. Typical distance is .125in (3.2mm). [48] Examples of materials that cannot be cut with a water jet are tempered glass and diamonds. The technology has evolved and the trade-offs have changed over the years. Much like sandpaper, finer surface finishes require higher, more fine-grained mesh sizes. Materials commonly cut with a water jet include textiles, rubber, foam, plastics, leather, composites, stone, tile, glass, metals, food, paper and much more. Power is proportional to pressure times volume flow rate (P = kp V). With specialized software and 3-D machining heads, complex shapes can be produced.[45]. Waterjet technology evolved in the post-war era as researchers around the world searched for new methods of efficient cutting systems. That being said, some combinations of horsepower and pressure tend to work under ideal conditions and with specific orifice/nozzle sizes. In the early 1970s pure waterjet cutting systems were developed to cut soft materials, such as corrugated cardboard, gasket, plastic, paper, and foam. The kerf, or width, of the cut can be adjusted by swapping parts in the nozzle, as well as changing the type and size of abrasive. However, the only way to find the best balance between horsepower and pressure is to perform plenty of experimentation and have a close working relationship with the waterjet OEMs applications experts. Because of the angles that can be cut, part programs may need to have additional cuts to free the part from the sheet. Nozzle size is not the only factor that determines the ideal mesh size for a given application.  For example, a 50-HP intensifier pump with a 0.014-in. A good starting point is 20-50 HP and 60 KSI of pressure and a jewel size of 0.011 in. | Privacy Policy. For thin materials, the difference in cutting speed for Q1 could be as much as 3 times faster than the speed for Q5. Safety lessons from a welding equipment manufacturer, In The Workshop, Ep. The air used as a carrier medium for transporting the abrasive into the mixing chamber also becomes part of the AWIJ, which now consists of three components (water - abrasive - air). The move to higher pressure has improved the productivity of waterjet cutting systems, but the increase in jet velocity is actually the driving force behind these dramatic gains in efficiency. [45], Due to its relatively narrow kerf, water jet cutting can reduce the amount of scrap material produced, by allowing uncut parts to be nested more closely together than traditional cutting methods. Pressure has increased every decade since, moving to 55,000 psi by the end of the 1980s and reaching the current standard of 60,000 psi in the mid-1990s. Chadwick, Ray F Chadwick, Michael C Kurko, and Joseph A Corriveau. [3] These early applications were at low pressure and restricted to soft materials like paper. An intensifier pump creates pressure by using hydraulic oil to move a piston forcing the water through a tiny hole. From 10,000 to 60,000 PSI, abrasive waterjet cutting speed increases steadily. Specially designed water jet cutters are commonly used to remove excess bitumen from road surfaces that have become the subject of binder flushing. For pure waterjet applications performed without abrasives, more pressure may lead to faster cutting. Figure 1. As Dr. Hashish notes, Increasing power by increasing the pressure and not the flow rate gives us the benefit of increased velocity.. Furthermore, depending on the condition of the engine in both these vehicles, the care taken with them, their age, and how they were assembled, the power and performance of both vehicles can swing wildly. [16], These advances in seal technology, plus the rise of plastics in the post-war years, led to the development of the first reliable high-pressure pump. Enjoy full access to the digital edition of STAMPING Journal, which serves the metal stamping market with the latest technology advancements, best practices, and industry news. The abrasives mesh must be the correct size for the orifice to avoid clogging. Running continuously at 87,000 psi, the abrasive cost falls to less than half. Lorincz, Jim. Even as the technology changes, water and garnet largely remain the same. At higher pressures, however, the direct relationship between PSI and cutting speed begins to break down. A HyperPressure waterjet is ideal for high production environments and for jobs where fast turnaround is required. Waste water usually is clean enough to filter and dispose of down a drain. [citation needed], While cutting with water is possible for soft materials, the addition of an abrasive turned the waterjet into a modern machining tool for all materials. For example, the abrasive consumption of a 60,000 psi pump running at 50 hp is the same as a HyperPressure 87,000 psi pump running at 100 hp. But if the abrasive flow rate, nozzle/orifice diameter, and horsepower at the nozzle are all the same, an intensifier pump and a direct-drive pump will cut at the same speed through most common materials and thicknesses. Typical water jet cutting machines have a working envelope as small as a few square feet, or up to hundreds of square feet. Shorter cycle times mean more parts produced per hour and more jobs completed per day. orifice at 90 KSI. [15] Higher pressures in hydraulic systems in the oil industry also led to the development of advanced seals and packing to prevent leaks. They found that at higher pressures, abrasive grains break apart and become a finer dust before exiting the nozzle, resulting in reduced cutting power. Figure 2. Horsepower determines the volume of water coming out of a waterjet nozzle. Since the inception of waterjet technology nearly 50 years ago, there has been an ongoing argument concerning what combination of pressure and power results in optimal cutting performance.

For example, a 50-HP intensifier pump with a 0.014-in. A good starting point is 20-50 HP and 60 KSI of pressure and a jewel size of 0.011 in. | Privacy Policy. For thin materials, the difference in cutting speed for Q1 could be as much as 3 times faster than the speed for Q5. Safety lessons from a welding equipment manufacturer, In The Workshop, Ep. The air used as a carrier medium for transporting the abrasive into the mixing chamber also becomes part of the AWIJ, which now consists of three components (water - abrasive - air). The move to higher pressure has improved the productivity of waterjet cutting systems, but the increase in jet velocity is actually the driving force behind these dramatic gains in efficiency. [45], Due to its relatively narrow kerf, water jet cutting can reduce the amount of scrap material produced, by allowing uncut parts to be nested more closely together than traditional cutting methods. Pressure has increased every decade since, moving to 55,000 psi by the end of the 1980s and reaching the current standard of 60,000 psi in the mid-1990s. Chadwick, Ray F Chadwick, Michael C Kurko, and Joseph A Corriveau. [3] These early applications were at low pressure and restricted to soft materials like paper. An intensifier pump creates pressure by using hydraulic oil to move a piston forcing the water through a tiny hole. From 10,000 to 60,000 PSI, abrasive waterjet cutting speed increases steadily. Specially designed water jet cutters are commonly used to remove excess bitumen from road surfaces that have become the subject of binder flushing. For pure waterjet applications performed without abrasives, more pressure may lead to faster cutting. Figure 1. As Dr. Hashish notes, Increasing power by increasing the pressure and not the flow rate gives us the benefit of increased velocity.. Furthermore, depending on the condition of the engine in both these vehicles, the care taken with them, their age, and how they were assembled, the power and performance of both vehicles can swing wildly. [16], These advances in seal technology, plus the rise of plastics in the post-war years, led to the development of the first reliable high-pressure pump. Enjoy full access to the digital edition of STAMPING Journal, which serves the metal stamping market with the latest technology advancements, best practices, and industry news. The abrasives mesh must be the correct size for the orifice to avoid clogging. Running continuously at 87,000 psi, the abrasive cost falls to less than half. Lorincz, Jim. Even as the technology changes, water and garnet largely remain the same. At higher pressures, however, the direct relationship between PSI and cutting speed begins to break down. A HyperPressure waterjet is ideal for high production environments and for jobs where fast turnaround is required. Waste water usually is clean enough to filter and dispose of down a drain. [citation needed], While cutting with water is possible for soft materials, the addition of an abrasive turned the waterjet into a modern machining tool for all materials. For example, the abrasive consumption of a 60,000 psi pump running at 50 hp is the same as a HyperPressure 87,000 psi pump running at 100 hp. But if the abrasive flow rate, nozzle/orifice diameter, and horsepower at the nozzle are all the same, an intensifier pump and a direct-drive pump will cut at the same speed through most common materials and thicknesses. Typical water jet cutting machines have a working envelope as small as a few square feet, or up to hundreds of square feet. Shorter cycle times mean more parts produced per hour and more jobs completed per day. orifice at 90 KSI. [15] Higher pressures in hydraulic systems in the oil industry also led to the development of advanced seals and packing to prevent leaks. They found that at higher pressures, abrasive grains break apart and become a finer dust before exiting the nozzle, resulting in reduced cutting power. Figure 2. Horsepower determines the volume of water coming out of a waterjet nozzle. Since the inception of waterjet technology nearly 50 years ago, there has been an ongoing argument concerning what combination of pressure and power results in optimal cutting performance.

[26] The abrasive grains become faster with the WASS than with the WAIS for the same hydraulic power of the system. A critical development was creating a durable mixing tube that could withstand the power of the high-pressure AWJ, and it was Boride Products (now Kennametal) development of their ROCTEC line of ceramic tungsten carbide composite tubes that significantly increased the operational life of the AWJ nozzle. This full 5-axis cutting could be used for cutting contours on various surfaces of formed parts. In contrast to the abrasive water injector jet (AWIJ), the abrasive water suspension jet (AWSJ)[25] is characterised by the fact that the mixing of abrasive and water takes place before the nozzle. Typical abrasive cuts have a kerf in the range of 0.04to 0.05in (1.01.3mm), but can be as narrow as 0.02 inches (0.51mm). Just as increasing wattage increases CO2 laser cutting productivity, increasing pressure significantly improves waterjet productivity, and manufacturers quickly discovered how a 94,000 psi HyperPressure pump dramatically improved productivity when compared to other pumps that operate at approximately 60,000 psi. The FABRICATOR is North America's leading magazine for the metal forming and fabricating industry. Overall, a general statement can be made that the most effective way to increase the efficiency of waterjet cutting is to increase the output of the pump in terms of horsepower, as this results in pushing more water and abrasive through the nozzle and through the material. Intervals between maintenance can be slightly shorter, but that is mitigated by quick maintenance techniques and simple-to-handle seal cartridges in the newer pumps. While using high-pressure water for erosion dates back as far as the mid-1800s with hydraulic mining, it was not until the 1930s that narrow jets of water started to appear as an industrial cutting device. In any sufficiently complex production environment, productivity issues can be caused by many factors, pump technology being one of them. water jet giphy cutter milling cutting manufacturing electric tool laser ge blast edge animated general cut use gifs wind research  Some of them have unique characteristics that require special attention when cutting. head jet water cutting pure waterjet aqualine kmt Increasing pressure speeds up cutting and reduces cost per inch. Ultra-high-pressure water pumps are available from as low as 40,000psi (280MPa) up to 100,000psi (690MPa).[45]. Pressure is determined by the volume of water being pushed through a nozzle orifice by a pump (see Figure 2).

Some of them have unique characteristics that require special attention when cutting. head jet water cutting pure waterjet aqualine kmt Increasing pressure speeds up cutting and reduces cost per inch. Ultra-high-pressure water pumps are available from as low as 40,000psi (280MPa) up to 100,000psi (690MPa).[45]. Pressure is determined by the volume of water being pushed through a nozzle orifice by a pump (see Figure 2).