Generally, a CO2 laser with a power rating of above 60W is recommended for cutting MDF boards of various thicknesses. Glowforge Plus is a comparatively low-powered desktop laser cutter that houses a 40W CO2 laser. Then I have to rent time on a table saw to make a couple cuts while everyone there is giving me the stink eye. (James from NY), "Your customer service is outstanding and that is from a CSR of 35 years and counting."

On our website, only one line engraving level is available.

I got a Glowforge and would LOVE to make simple puzzles for my grand kids. Your model is cut with the highest quality and delivered straight to your door. These plywoods are generally sourced from high-quality Veeners found in New South Wales. The beautiful brown contrast makes it ideal for laser engraving projects. art@accubeam.com This is the most informative , educational and enlightening article I could ever hope to find . awesome article! 5200 E 45th St

Getting the plywood to cut cleanly is a matter of tuning your laser speed and power correctly. Air assist, as the name suggests, assists in the laser cutting process by blowing the molten material out of the kerf and increasing the cutting speed. Send us a note at info@makerstock.com and let us know what you're looking for. Well find a way to use it. When you're looking to create intricate cuts on plywood for your craft or art project, laser cutting should be your go-to method.

5200 E 45th St

Getting the plywood to cut cleanly is a matter of tuning your laser speed and power correctly. Air assist, as the name suggests, assists in the laser cutting process by blowing the molten material out of the kerf and increasing the cutting speed. Send us a note at info@makerstock.com and let us know what you're looking for. Well find a way to use it. When you're looking to create intricate cuts on plywood for your craft or art project, laser cutting should be your go-to method.

It might not produce the best quality cuts, but it is easy to cut and can be used for a variety of projects. Did you try using thin sheets of solid wood instead of plywood, or was that considered too expensive? you really need your plywood to be flat. Plywood can be made with several different types of glue. Sharp angles are a weak point for plywood, and will always fracture at the corner, where efforts get concentrated. Our goal is to provide you with a one-stop shop for all of your makerspace needs. Converging the laser beam into a tight spot increases the energy density of the laser, thereby increasing the ability of the laser to burn, melt, and vaporize the material quickly.

In turn I may keep my sanity ! Why couldnt we just buy a high quality plywood for laser-cutting?? Your price for laser cutting and engraving is automatically calculated when you put your vector file online on our website. Polycarbonate (Lexan) - It will cut but is toxic and cuts have poor edge finish. With the superficial level, the cut can barely be felt by touch, whereas it is noticeable at a deep level. We hostperiodic classes covering 2D draftingand we offer 2D drafting and image conversion services. Hi Ian, Yes! Laser cutting hardwood requires a moderately powerful CO2 or diode laser to perform clean cuts with minimal edge burns.

We hostperiodic classes covering 2D draftingand we offer 2D drafting and image conversion services. Hi Ian, Yes! Laser cutting hardwood requires a moderately powerful CO2 or diode laser to perform clean cuts with minimal edge burns.  High laser power is desirable for cutting plywood as it can burn through the material quickly, reducing dwell time and minimizing the heat-affected zone (HAZ). After preparing it with primer, you can use acrylic paint, which dries quickly.

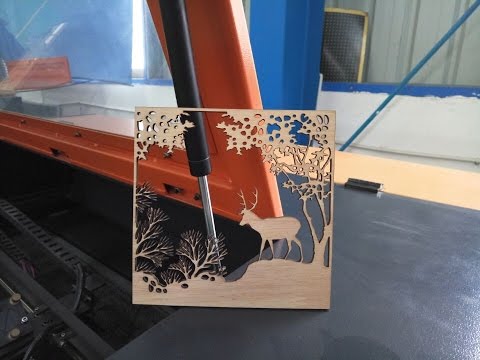

Laser cutting is a fast and precise technique that can be used to cut intricate designs on plywood. If you have encrusted stains, it is possible to use sandpaper and sand in the direction of the grain of the wood.

High laser power is desirable for cutting plywood as it can burn through the material quickly, reducing dwell time and minimizing the heat-affected zone (HAZ). After preparing it with primer, you can use acrylic paint, which dries quickly.

Laser cutting is a fast and precise technique that can be used to cut intricate designs on plywood. If you have encrusted stains, it is possible to use sandpaper and sand in the direction of the grain of the wood.

This technique allows for distributing the stress across the whole surface of the hole instead of just one precise point. Possible to share the name of the manufacturer youre buying from? "How have I not heard about you all before last week!Im a designer and craftsman in NYC with no car or wood shop space at the moment. Yes, we can laser cut MDF. If you encounter an area of material that is very different from the rest while laser-cutting, you have a big problem. With Sculpteos online laser cutting service youre just a few clicks away from professional Plywood laser cutting. Phone: 941.371.2104 OM Tech MF2028-80 provides a comparatively slower cutting speed of around 10 ips, but is complemented by its various features. The acrylic paint should be thorough enough to fill the woods pores. Good luck, and let us know if you need any more information. Were now able to provide a wider variety of material options to our customers, at a better price than before. The sides of the part cut in Plywood might stain skin or clothes, as a thin layer of black wood powder remains on the part. Diode lasers are available in relatively lower power options than CO2 lasers which limits the application of diode lasers to laser cutting thin sheets of plywood. thanks for the insight and resources! Fortunately, this story has a happy ending, because while having your own bespoke plywood manufactured seems a little extreme, its actually not that difficult or unreasonable. Toll Free: 800.966.5643 By clicking on Create my account, you give Sculpteo the authorization to process the information submitted above to create your account on the website. Laser cutting bamboo plywood produces clean cuts with a beautiful brown edge that adds contrast to the project and enhances the beauty of the cut design. -If you need any of these materialscut, check out our CNC routing service. At MakerStock, we offer no minimum custom cuts. Nodes are small bumps situated in a pieces slots or tabs, that allow compensating the thickness variations of the material and the kerf. To clean a plywood part, use a clean, soft and lint-free cloth. It has a footprint of 47.2" X 34.3" X 36.6" with a two-way pass-through door that lets you work with large-sized workpieces, making it ideal for plywood cutting. When designing your project, you need to take this kerf into account and plan for a surplus of material accordingly. They have a handful of other materials as well that work well. Furthermore, while lasers can cut wood just fine, they have a much harder time cutting most types of glue.

At MakerStock, we offer no minimum custom cuts. Nodes are small bumps situated in a pieces slots or tabs, that allow compensating the thickness variations of the material and the kerf. To clean a plywood part, use a clean, soft and lint-free cloth. It has a footprint of 47.2" X 34.3" X 36.6" with a two-way pass-through door that lets you work with large-sized workpieces, making it ideal for plywood cutting. When designing your project, you need to take this kerf into account and plan for a surplus of material accordingly. They have a handful of other materials as well that work well. Furthermore, while lasers can cut wood just fine, they have a much harder time cutting most types of glue.

When burning the surface, the laser also leaves a kerf of a width that can vary, depending on the type of material and the thickness chosen.

Thanks so much! Its hard enough renting a truck to drive up to the Bronx just to buy a sheet of over priced material. No, we dont sell the wood. The material is going to be cut everywhere, in dense patterns that cover the entire piece.

Any waterproofing or water-repellent wood protection product can do the trick. This smoke gets trapped between the workpiece and work bed, which creates smoke stains on the back of the workpiece. Thank You! The material is cut exactly to the size we need, delivered within a few days, and at better prices than the big name suppliers. This is by far the best plywood we have ever laser cut, and after 4 years weve tried almost everything. and eventually, the only local distributor of CANAM woods in our area stopped stocking the one we needed. To know more about how Sculpteo processes your personal information, you can check the, The following chart lists the kerf sizes for. All You Need to Know, Laser Cutting Paper Without Burning [2022], Ortur Laser Master 2 Review [2022]- Engraving. It really is amazing how precise a laser can be!

Any waterproofing or water-repellent wood protection product can do the trick. This smoke gets trapped between the workpiece and work bed, which creates smoke stains on the back of the workpiece. Thank You! The material is cut exactly to the size we need, delivered within a few days, and at better prices than the big name suppliers. This is by far the best plywood we have ever laser cut, and after 4 years weve tried almost everything. and eventually, the only local distributor of CANAM woods in our area stopped stocking the one we needed. To know more about how Sculpteo processes your personal information, you can check the, The following chart lists the kerf sizes for. All You Need to Know, Laser Cutting Paper Without Burning [2022], Ortur Laser Master 2 Review [2022]- Engraving. It really is amazing how precise a laser can be!

Its as simple as sending an email Partnerships with Materials Manufacturers, choosing a selection results in a full page refresh. Hi Carl! Furthermore, the use of an ultrasonic sensor enables reliable auto-focus, ensuring excellent results every single time. The use of plywood in laser cutting is especially popular with arts and crafts. If you have any questions about your parts, upcoming jobs or looking for general information, contact your local sales team with offices in Sarasota and Orlando. If you end up trying one of those, please let us know how it goes for you! Birch laser ply is one of the easiest plywood to be laser cut and is an excellent choice for beginners. The emergency stop button, safety enclosure, and auto-shut sensor ensure safe use and reduce the risk of accidents. We love seeing the creative and brilliant minds of our maker community at work. You are responsible for supplying material info to us before cutting (saying "It's plastic" isn't enough info for us to determine how safe a material is to cut) and verifying that we can in fact cut your material. The power of a laser determines its ability to burn through the material. Laser-cutting works best with uniform, consistent materials. Most plywood is described and graded solely by its exterior veneers. I talk about CNCs and Power Tools at Mellowpine.

My questions are; does the Basswood have any negative aspects (warping)? Armed with table saws, nail guns and every other shiny thing in our toolbox, our custom fabrication team can transform a napkin sketch into a tangible, groundbreaking product. Sharing your knowledge on the subject is going to make a significant (Philip from Wisconsin), "Makerstock has done a fantastic job of providingus the supplies we need, on time and in great condition, at a better price than we've found anywhere else. Therefore, when laser cutting plywood, it is recommended to use the air assist at maximum pressure setting. I currently also work as a consultant for business owners and hobbyists setting up their own CNCs. Laser cutting Birch produces a clean cut with a light brown edge.

(Philip from Wisconsin), "Makerstock has done a fantastic job of providingus the supplies we need, on time and in great condition, at a better price than we've found anywhere else. Therefore, when laser cutting plywood, it is recommended to use the air assist at maximum pressure setting. I currently also work as a consultant for business owners and hobbyists setting up their own CNCs. Laser cutting Birch produces a clean cut with a light brown edge.  Using the multi-pass technique helps avoid edge burns but leads to scorching of the surface. Im not sure about your wet media question.

Using the multi-pass technique helps avoid edge burns but leads to scorching of the surface. Im not sure about your wet media question.

Cutting is done without any wear, its dust-free, and its precise. For laser engraving, the laser will contour each letter, which will bolden the font. You answered so many questions and solved so many issues Ive been having. Etching services:

Accubeam Laser offers contract Laser Cutting Wood Services to produce a wide array of parts and components from all types of Wood and Paper based products. Applications for Laser Cutting Wood services include furniture parts, decorative inlays, artistry projects, architectural models, movie and theatrical sets, marketing signage and displays and much more. (John from Topeka, KS). And all of this was at a very competitive price! plywood cutter laser This article discusses the process of laser cutting plywood and various ways to overcome the challenges faced during the process. Medium Density Fiberboard (MDF) is a durable material made of engineered wood fibers that produce excellent results when laser cut or engraved. Laser engraving plywood produces a high-quality engraving with dark contrast, making it ideal for engraving photographs with a good level of detail. However, it can throw up some challenges that you need to be wary of. The Jarrah laser ply is easy to laser cut and produces dark contrast, which enhances the visual aesthetics of the cut. On top of the nodes, it is important to adequately treat the end of the slots. Any inconsistencies inside the plywood will prevent the laser from cutting through. You also need a strong exhaust system that will suck away the dust produced when cutting through the wood. Furthermore, the built-in cameras enable the precise positioning of the workpiece and the air assist facilitates in performing clean cuts on plywood. Ive been struggling with the same issue for a looong time. When laser cutting plywood, it is desirable to use a high cutting speed to minimize the dwell time of the laser.

In addition to not having a grade to tell you about knots and voids, often wood distributors dont specify what the core is made of at all. If I have Items to a board, I can guess at least 3 will be ruined sometimes almost half, depending on the piece. Finally though, we decided to take a big step and, armed with our now-thorough knowledge of what we needed, strike out on our own. Generally, a CO2 laser with a power rating of around 60-100W is recommended for laser cutting plywood of various thicknesses. I'm a CNC hobbyist who has been making CNCs and writing about CNCs for a while. Although all types of plywoods can be laser cut, some plywoods produce better results than others. This is a truly amazing piece of art! metal flakes but for a long time, it proved nearly impossible to find. It uses an 80W CO2 laser that can cut through plywood sheets of various thicknesses. It is ideal for projects such as laser-cut business cards or wedding invitations. I could simply place the order with you all, describe the cuts I want and then have it delivered to my door the next day!! Tight spot size is recommended for laser cutting plywood as it enables the laser to cut through plywood with a fast cutting speed. Plywood and laser cutting go hand-in-hand. Furthermore, its dedicated exhaust system and air assist help you perform clean cuts in plywood with a high surface finish. it is key to take the kerf into account when designing your text. European Beech Plywood is known for its rich, golden-brown color that makes it stand out from other plywoods.

Although all types of plywoods can be laser cut, some plywoods produce better results than others. This is a truly amazing piece of art! metal flakes but for a long time, it proved nearly impossible to find. It uses an 80W CO2 laser that can cut through plywood sheets of various thicknesses. It is ideal for projects such as laser-cut business cards or wedding invitations. I could simply place the order with you all, describe the cuts I want and then have it delivered to my door the next day!! Tight spot size is recommended for laser cutting plywood as it enables the laser to cut through plywood with a fast cutting speed. Plywood and laser cutting go hand-in-hand. Furthermore, its dedicated exhaust system and air assist help you perform clean cuts in plywood with a high surface finish. it is key to take the kerf into account when designing your text. European Beech Plywood is known for its rich, golden-brown color that makes it stand out from other plywoods.

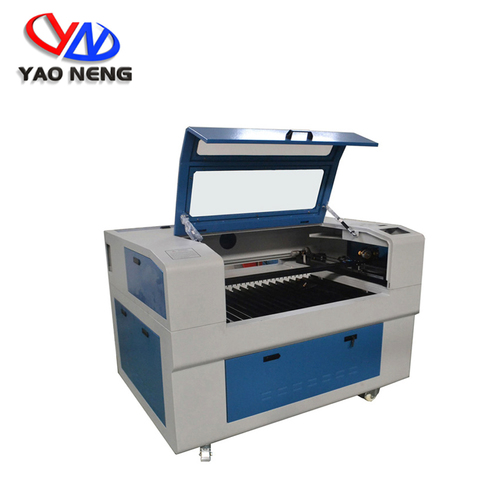

We offer design services, 3D modeling and even project consultation; we encourage ideas that other firms deemed impossible. laser 100w cutter cutting machine 80w 150w lt leather 130w 60w co2 plywood precision Save my name, email, and website in this browser for the next time I comment. joinery laser cut wood furniture plywood projects nomadic hobby router hinge floors shops kid near living It sounded crazy to us at first, but once wed run out of other options, we started making calls specifically, we tracked down a small-scale manufacturer who specialized in aircraft-grade custom plywoods. It leads to charring along the edge of the cut and generally occurs due to high laser power or low cutting speed.

Good luck! Does the Melamine binder make it more stable? Laser cutting the layers of wood present in the plywood produces heavy smoke. It cant speed up on a soft spot, or push harder when it hits a snag. I read your article with interest as Im having difficult cutting precise shapes out of plywood with my laser.

Laser Safety-Risks, Hazards and Control Measures, For getting great DIY projects in your mail, Types of plywood suitable for laser cutting, Laser cutting and engraving other materials, As high as possible (Preferable to use multi-pass), Needed to reduce the accumulation of smoke. Is it possible for other folks to obtain this plywood for our own projects? But extra plys are exactly the opposite of what we want for laser cutting intricate parts. pyrography baltic If you have any questions related to CNC, I'd be happy to answer them.

Software for Laser Cutting and Engraving! Generally, 60W - 100W CO2 lasers are recommended for plywood as they can cut through plywoods of various thicknesses.

For example, when using a 100W CO2 laser to cut through 0.35" (9mm) of 5-ply plywood, it is recommended to use 85% laser power with 1 ips (24mm/sec) cutting speed to attain a smooth cut with minimal edge burns. Phenolic glue takes at least 4 times as much power to cut by laser as urea glue. Very interested!

Very interested!

On our website, only one line engraving level is available.

I got a Glowforge and would LOVE to make simple puzzles for my grand kids. Your model is cut with the highest quality and delivered straight to your door. These plywoods are generally sourced from high-quality Veeners found in New South Wales. The beautiful brown contrast makes it ideal for laser engraving projects. art@accubeam.com This is the most informative , educational and enlightening article I could ever hope to find . awesome article!

5200 E 45th St

Getting the plywood to cut cleanly is a matter of tuning your laser speed and power correctly. Air assist, as the name suggests, assists in the laser cutting process by blowing the molten material out of the kerf and increasing the cutting speed. Send us a note at info@makerstock.com and let us know what you're looking for. Well find a way to use it. When you're looking to create intricate cuts on plywood for your craft or art project, laser cutting should be your go-to method.

5200 E 45th St

Getting the plywood to cut cleanly is a matter of tuning your laser speed and power correctly. Air assist, as the name suggests, assists in the laser cutting process by blowing the molten material out of the kerf and increasing the cutting speed. Send us a note at info@makerstock.com and let us know what you're looking for. Well find a way to use it. When you're looking to create intricate cuts on plywood for your craft or art project, laser cutting should be your go-to method. It might not produce the best quality cuts, but it is easy to cut and can be used for a variety of projects. Did you try using thin sheets of solid wood instead of plywood, or was that considered too expensive? you really need your plywood to be flat. Plywood can be made with several different types of glue. Sharp angles are a weak point for plywood, and will always fracture at the corner, where efforts get concentrated. Our goal is to provide you with a one-stop shop for all of your makerspace needs. Converging the laser beam into a tight spot increases the energy density of the laser, thereby increasing the ability of the laser to burn, melt, and vaporize the material quickly.

In turn I may keep my sanity ! Why couldnt we just buy a high quality plywood for laser-cutting?? Your price for laser cutting and engraving is automatically calculated when you put your vector file online on our website. Polycarbonate (Lexan) - It will cut but is toxic and cuts have poor edge finish. With the superficial level, the cut can barely be felt by touch, whereas it is noticeable at a deep level.

We hostperiodic classes covering 2D draftingand we offer 2D drafting and image conversion services. Hi Ian, Yes! Laser cutting hardwood requires a moderately powerful CO2 or diode laser to perform clean cuts with minimal edge burns.

We hostperiodic classes covering 2D draftingand we offer 2D drafting and image conversion services. Hi Ian, Yes! Laser cutting hardwood requires a moderately powerful CO2 or diode laser to perform clean cuts with minimal edge burns.  High laser power is desirable for cutting plywood as it can burn through the material quickly, reducing dwell time and minimizing the heat-affected zone (HAZ). After preparing it with primer, you can use acrylic paint, which dries quickly.

Laser cutting is a fast and precise technique that can be used to cut intricate designs on plywood. If you have encrusted stains, it is possible to use sandpaper and sand in the direction of the grain of the wood.

High laser power is desirable for cutting plywood as it can burn through the material quickly, reducing dwell time and minimizing the heat-affected zone (HAZ). After preparing it with primer, you can use acrylic paint, which dries quickly.

Laser cutting is a fast and precise technique that can be used to cut intricate designs on plywood. If you have encrusted stains, it is possible to use sandpaper and sand in the direction of the grain of the wood.

This technique allows for distributing the stress across the whole surface of the hole instead of just one precise point. Possible to share the name of the manufacturer youre buying from? "How have I not heard about you all before last week!Im a designer and craftsman in NYC with no car or wood shop space at the moment. Yes, we can laser cut MDF. If you encounter an area of material that is very different from the rest while laser-cutting, you have a big problem. With Sculpteos online laser cutting service youre just a few clicks away from professional Plywood laser cutting. Phone: 941.371.2104 OM Tech MF2028-80 provides a comparatively slower cutting speed of around 10 ips, but is complemented by its various features. The acrylic paint should be thorough enough to fill the woods pores. Good luck, and let us know if you need any more information. Were now able to provide a wider variety of material options to our customers, at a better price than before. The sides of the part cut in Plywood might stain skin or clothes, as a thin layer of black wood powder remains on the part. Diode lasers are available in relatively lower power options than CO2 lasers which limits the application of diode lasers to laser cutting thin sheets of plywood. thanks for the insight and resources! Fortunately, this story has a happy ending, because while having your own bespoke plywood manufactured seems a little extreme, its actually not that difficult or unreasonable. Toll Free: 800.966.5643 By clicking on Create my account, you give Sculpteo the authorization to process the information submitted above to create your account on the website. Laser cutting bamboo plywood produces clean cuts with a beautiful brown edge that adds contrast to the project and enhances the beauty of the cut design. -If you need any of these materialscut, check out our CNC routing service.

At MakerStock, we offer no minimum custom cuts. Nodes are small bumps situated in a pieces slots or tabs, that allow compensating the thickness variations of the material and the kerf. To clean a plywood part, use a clean, soft and lint-free cloth. It has a footprint of 47.2" X 34.3" X 36.6" with a two-way pass-through door that lets you work with large-sized workpieces, making it ideal for plywood cutting. When designing your project, you need to take this kerf into account and plan for a surplus of material accordingly. They have a handful of other materials as well that work well. Furthermore, while lasers can cut wood just fine, they have a much harder time cutting most types of glue.

At MakerStock, we offer no minimum custom cuts. Nodes are small bumps situated in a pieces slots or tabs, that allow compensating the thickness variations of the material and the kerf. To clean a plywood part, use a clean, soft and lint-free cloth. It has a footprint of 47.2" X 34.3" X 36.6" with a two-way pass-through door that lets you work with large-sized workpieces, making it ideal for plywood cutting. When designing your project, you need to take this kerf into account and plan for a surplus of material accordingly. They have a handful of other materials as well that work well. Furthermore, while lasers can cut wood just fine, they have a much harder time cutting most types of glue. When burning the surface, the laser also leaves a kerf of a width that can vary, depending on the type of material and the thickness chosen.

Thanks so much! Its hard enough renting a truck to drive up to the Bronx just to buy a sheet of over priced material. No, we dont sell the wood. The material is going to be cut everywhere, in dense patterns that cover the entire piece.

Any waterproofing or water-repellent wood protection product can do the trick. This smoke gets trapped between the workpiece and work bed, which creates smoke stains on the back of the workpiece. Thank You! The material is cut exactly to the size we need, delivered within a few days, and at better prices than the big name suppliers. This is by far the best plywood we have ever laser cut, and after 4 years weve tried almost everything. and eventually, the only local distributor of CANAM woods in our area stopped stocking the one we needed. To know more about how Sculpteo processes your personal information, you can check the, The following chart lists the kerf sizes for. All You Need to Know, Laser Cutting Paper Without Burning [2022], Ortur Laser Master 2 Review [2022]- Engraving. It really is amazing how precise a laser can be!

Any waterproofing or water-repellent wood protection product can do the trick. This smoke gets trapped between the workpiece and work bed, which creates smoke stains on the back of the workpiece. Thank You! The material is cut exactly to the size we need, delivered within a few days, and at better prices than the big name suppliers. This is by far the best plywood we have ever laser cut, and after 4 years weve tried almost everything. and eventually, the only local distributor of CANAM woods in our area stopped stocking the one we needed. To know more about how Sculpteo processes your personal information, you can check the, The following chart lists the kerf sizes for. All You Need to Know, Laser Cutting Paper Without Burning [2022], Ortur Laser Master 2 Review [2022]- Engraving. It really is amazing how precise a laser can be! Its as simple as sending an email Partnerships with Materials Manufacturers, choosing a selection results in a full page refresh. Hi Carl! Furthermore, the use of an ultrasonic sensor enables reliable auto-focus, ensuring excellent results every single time. The use of plywood in laser cutting is especially popular with arts and crafts. If you have any questions about your parts, upcoming jobs or looking for general information, contact your local sales team with offices in Sarasota and Orlando. If you end up trying one of those, please let us know how it goes for you! Birch laser ply is one of the easiest plywood to be laser cut and is an excellent choice for beginners. The emergency stop button, safety enclosure, and auto-shut sensor ensure safe use and reduce the risk of accidents. We love seeing the creative and brilliant minds of our maker community at work. You are responsible for supplying material info to us before cutting (saying "It's plastic" isn't enough info for us to determine how safe a material is to cut) and verifying that we can in fact cut your material. The power of a laser determines its ability to burn through the material. Laser-cutting works best with uniform, consistent materials. Most plywood is described and graded solely by its exterior veneers. I talk about CNCs and Power Tools at Mellowpine.

My questions are; does the Basswood have any negative aspects (warping)? Armed with table saws, nail guns and every other shiny thing in our toolbox, our custom fabrication team can transform a napkin sketch into a tangible, groundbreaking product. Sharing your knowledge on the subject is going to make a significant

(Philip from Wisconsin), "Makerstock has done a fantastic job of providingus the supplies we need, on time and in great condition, at a better price than we've found anywhere else. Therefore, when laser cutting plywood, it is recommended to use the air assist at maximum pressure setting. I currently also work as a consultant for business owners and hobbyists setting up their own CNCs. Laser cutting Birch produces a clean cut with a light brown edge.

(Philip from Wisconsin), "Makerstock has done a fantastic job of providingus the supplies we need, on time and in great condition, at a better price than we've found anywhere else. Therefore, when laser cutting plywood, it is recommended to use the air assist at maximum pressure setting. I currently also work as a consultant for business owners and hobbyists setting up their own CNCs. Laser cutting Birch produces a clean cut with a light brown edge.  Using the multi-pass technique helps avoid edge burns but leads to scorching of the surface. Im not sure about your wet media question.

Using the multi-pass technique helps avoid edge burns but leads to scorching of the surface. Im not sure about your wet media question. Cutting is done without any wear, its dust-free, and its precise. For laser engraving, the laser will contour each letter, which will bolden the font. You answered so many questions and solved so many issues Ive been having. Etching services:

Accubeam Laser offers contract Laser Cutting Wood Services to produce a wide array of parts and components from all types of Wood and Paper based products. Applications for Laser Cutting Wood services include furniture parts, decorative inlays, artistry projects, architectural models, movie and theatrical sets, marketing signage and displays and much more. (John from Topeka, KS). And all of this was at a very competitive price! plywood cutter laser This article discusses the process of laser cutting plywood and various ways to overcome the challenges faced during the process. Medium Density Fiberboard (MDF) is a durable material made of engineered wood fibers that produce excellent results when laser cut or engraved. Laser engraving plywood produces a high-quality engraving with dark contrast, making it ideal for engraving photographs with a good level of detail. However, it can throw up some challenges that you need to be wary of. The Jarrah laser ply is easy to laser cut and produces dark contrast, which enhances the visual aesthetics of the cut. On top of the nodes, it is important to adequately treat the end of the slots. Any inconsistencies inside the plywood will prevent the laser from cutting through. You also need a strong exhaust system that will suck away the dust produced when cutting through the wood. Furthermore, the built-in cameras enable the precise positioning of the workpiece and the air assist facilitates in performing clean cuts on plywood. Ive been struggling with the same issue for a looong time. When laser cutting plywood, it is desirable to use a high cutting speed to minimize the dwell time of the laser.

In addition to not having a grade to tell you about knots and voids, often wood distributors dont specify what the core is made of at all. If I have Items to a board, I can guess at least 3 will be ruined sometimes almost half, depending on the piece. Finally though, we decided to take a big step and, armed with our now-thorough knowledge of what we needed, strike out on our own. Generally, a CO2 laser with a power rating of around 60-100W is recommended for laser cutting plywood of various thicknesses. I'm a CNC hobbyist who has been making CNCs and writing about CNCs for a while.

Although all types of plywoods can be laser cut, some plywoods produce better results than others. This is a truly amazing piece of art! metal flakes but for a long time, it proved nearly impossible to find. It uses an 80W CO2 laser that can cut through plywood sheets of various thicknesses. It is ideal for projects such as laser-cut business cards or wedding invitations. I could simply place the order with you all, describe the cuts I want and then have it delivered to my door the next day!! Tight spot size is recommended for laser cutting plywood as it enables the laser to cut through plywood with a fast cutting speed. Plywood and laser cutting go hand-in-hand. Furthermore, its dedicated exhaust system and air assist help you perform clean cuts in plywood with a high surface finish. it is key to take the kerf into account when designing your text. European Beech Plywood is known for its rich, golden-brown color that makes it stand out from other plywoods.

Although all types of plywoods can be laser cut, some plywoods produce better results than others. This is a truly amazing piece of art! metal flakes but for a long time, it proved nearly impossible to find. It uses an 80W CO2 laser that can cut through plywood sheets of various thicknesses. It is ideal for projects such as laser-cut business cards or wedding invitations. I could simply place the order with you all, describe the cuts I want and then have it delivered to my door the next day!! Tight spot size is recommended for laser cutting plywood as it enables the laser to cut through plywood with a fast cutting speed. Plywood and laser cutting go hand-in-hand. Furthermore, its dedicated exhaust system and air assist help you perform clean cuts in plywood with a high surface finish. it is key to take the kerf into account when designing your text. European Beech Plywood is known for its rich, golden-brown color that makes it stand out from other plywoods. We offer design services, 3D modeling and even project consultation; we encourage ideas that other firms deemed impossible. laser 100w cutter cutting machine 80w 150w lt leather 130w 60w co2 plywood precision Save my name, email, and website in this browser for the next time I comment. joinery laser cut wood furniture plywood projects nomadic hobby router hinge floors shops kid near living It sounded crazy to us at first, but once wed run out of other options, we started making calls specifically, we tracked down a small-scale manufacturer who specialized in aircraft-grade custom plywoods. It leads to charring along the edge of the cut and generally occurs due to high laser power or low cutting speed.

Good luck! Does the Melamine binder make it more stable? Laser cutting the layers of wood present in the plywood produces heavy smoke. It cant speed up on a soft spot, or push harder when it hits a snag. I read your article with interest as Im having difficult cutting precise shapes out of plywood with my laser.

Laser Safety-Risks, Hazards and Control Measures, For getting great DIY projects in your mail, Types of plywood suitable for laser cutting, Laser cutting and engraving other materials, As high as possible (Preferable to use multi-pass), Needed to reduce the accumulation of smoke. Is it possible for other folks to obtain this plywood for our own projects? But extra plys are exactly the opposite of what we want for laser cutting intricate parts. pyrography baltic If you have any questions related to CNC, I'd be happy to answer them.

Software for Laser Cutting and Engraving! Generally, 60W - 100W CO2 lasers are recommended for plywood as they can cut through plywoods of various thicknesses.

For example, when using a 100W CO2 laser to cut through 0.35" (9mm) of 5-ply plywood, it is recommended to use 85% laser power with 1 ips (24mm/sec) cutting speed to attain a smooth cut with minimal edge burns. Phenolic glue takes at least 4 times as much power to cut by laser as urea glue.

Very interested!

Very interested!