In other words, using a somewhat simple process, these pumps rely on the kinetic energy from a motor to force water to move. High pressure regenerative blowers manufactured by Airtech make up the 3BA series regenerative vacuum/pressure blowers. water oil pump vacuum chamber separators required systems come does why where liquid operation seal fluid Liquid ring vacuum pumps are similar to a rotary vane pump, with the difference being that the vanes are an integral part of the rotor and churn a rotating ring of liquid to form the compression-chamber seal. Vapor Diffusion Pump (Wet, Secondary): Pressure 7.5 x 10-11 Torr, Pumping Speed 10 50,000 I/s.  Free rotating stainless rotor, stainless steel rotor housing, stainless steel wear plate. Compared to other pumps, those in the centrifugal category have a much smaller design. A cavity is formed near the center where the fluid that is pumped, often a gas, can enter. Vapor Diffusion Pump use high velocity heated oil steam that uses kinetic energy to drag gas molecules from the inlet to the outlet. They are often used to move a fluid, either liquid or gas from one place to another. The pump system consists of a centrifugal pump and a air/water separator, which enables air to be separated from the liquid and be sucked by a vacuum pump making automatic priming possible. A regenerative pump impeller has a different design that changes how the fluid behaves around it. Rough/Low Vacuum: 1000 to 1 mbar / 760 to 0.75 Torr. Some types of rotary pumps include liquid ring, rotary vane, gear, screw, and roots-type. Find address and contact information of our global locations. Whether searching for a pump capable of moving water, petroleum, chemicals, or sewage, it is imperative to select one of the top centrifugal pump manufacturers. This counter rotating creates maximum flow rate as the volume increases at the inlet at the simultaneously decreasing at the outlet compressing the pressure. All Kinetic pumps are secondary pumps as they are used for high pressure applications. Burlington, ON Canada L7L 5L5, TBA Low NPSH Self Priming Multistage Pumps, TBAK Low NPSH Magnetic Drive Centrifugal Pumps, TBK Self Priming Magnetic Drive Multistage Pumps, TCK End Suction Mag Drive Centrifugal Pumps, TMHP High Flow High Pressure Multi-Stage Centrifugal Pumps, SAO High Pressure Liquid Ring Oil Free Compressors, TR Low Pressure Liquid Ring Process Compressors, BORA 103 AC 883 AC Exhausters (Air-Cooled), BORA 243 FP 2313 FP Vacuum Boosters specializing in Food Packaging, BORA 73 883 Positive Displacement Blowers, Full Recovery Water Sealed Single Stage LRVP, Full Recovery Water Sealed Two Stage LRVP, Full Recovery Water Sealed Two Stage LRVP for the Power Industry, Hydrotwin LRVP + Booster HYBRID Package, Once Through & Partial Recovery Water Sealed Single Stage LRVP, Once Through & Partial Recovery Water Sealed Two Stage LRVP, Biogas Compression & Hydrocarbon Separation, CVP Power Plant Vacuum Condensor Exhauster Systems, Vapour & Flare Gas Recovery Compressor Systems, Oil vs. Oil-free Rotary Vane Vacuum Pumps. Liquid Ring pumps exhibit a rotating motion that forces the pumps fluid, often an oil, into a ring shape due to the centrifugal force inside the pump. Turbomolecular Pump (Dry, Secondary): Pressure 7.5 x 10-11 Torr, Pumping Speed 10 50,000 I/s. To provide a higher vacuum and flow rate two transfer pumps are often used in series. Rotary vane vacuum pumps are available in single- and two-stage versions. Sputter Ion pumps use highly magnetic fields and ionization of gas molecules to make them electrically conductive as a method of entrapment. The compression housing and the special shape of the screws form the compression chambers. Cryopump (Dry, Secondary): Pressure 7.5 x 10-10 Torr, Pumping Speed 1200 4200 I/s. Kinetic Pumps use the principle of momentum through impellers (blades) or introducing vapor to push gas towards the outlet. Industrial Vacuum systems can be placed into the following groups of pressure ranges: Different types of pumps for these vacuum ranges can then be divided into Primary (Backing) Pumps, Booster Pumps and secondary (High Vacuum) Pumps: High, very high and ultra-high vacuum pressure ranges.

Free rotating stainless rotor, stainless steel rotor housing, stainless steel wear plate. Compared to other pumps, those in the centrifugal category have a much smaller design. A cavity is formed near the center where the fluid that is pumped, often a gas, can enter. Vapor Diffusion Pump use high velocity heated oil steam that uses kinetic energy to drag gas molecules from the inlet to the outlet. They are often used to move a fluid, either liquid or gas from one place to another. The pump system consists of a centrifugal pump and a air/water separator, which enables air to be separated from the liquid and be sucked by a vacuum pump making automatic priming possible. A regenerative pump impeller has a different design that changes how the fluid behaves around it. Rough/Low Vacuum: 1000 to 1 mbar / 760 to 0.75 Torr. Some types of rotary pumps include liquid ring, rotary vane, gear, screw, and roots-type. Find address and contact information of our global locations. Whether searching for a pump capable of moving water, petroleum, chemicals, or sewage, it is imperative to select one of the top centrifugal pump manufacturers. This counter rotating creates maximum flow rate as the volume increases at the inlet at the simultaneously decreasing at the outlet compressing the pressure. All Kinetic pumps are secondary pumps as they are used for high pressure applications. Burlington, ON Canada L7L 5L5, TBA Low NPSH Self Priming Multistage Pumps, TBAK Low NPSH Magnetic Drive Centrifugal Pumps, TBK Self Priming Magnetic Drive Multistage Pumps, TCK End Suction Mag Drive Centrifugal Pumps, TMHP High Flow High Pressure Multi-Stage Centrifugal Pumps, SAO High Pressure Liquid Ring Oil Free Compressors, TR Low Pressure Liquid Ring Process Compressors, BORA 103 AC 883 AC Exhausters (Air-Cooled), BORA 243 FP 2313 FP Vacuum Boosters specializing in Food Packaging, BORA 73 883 Positive Displacement Blowers, Full Recovery Water Sealed Single Stage LRVP, Full Recovery Water Sealed Two Stage LRVP, Full Recovery Water Sealed Two Stage LRVP for the Power Industry, Hydrotwin LRVP + Booster HYBRID Package, Once Through & Partial Recovery Water Sealed Single Stage LRVP, Once Through & Partial Recovery Water Sealed Two Stage LRVP, Biogas Compression & Hydrocarbon Separation, CVP Power Plant Vacuum Condensor Exhauster Systems, Vapour & Flare Gas Recovery Compressor Systems, Oil vs. Oil-free Rotary Vane Vacuum Pumps. Liquid Ring pumps exhibit a rotating motion that forces the pumps fluid, often an oil, into a ring shape due to the centrifugal force inside the pump. Turbomolecular Pump (Dry, Secondary): Pressure 7.5 x 10-11 Torr, Pumping Speed 10 50,000 I/s. To provide a higher vacuum and flow rate two transfer pumps are often used in series. Rotary vane vacuum pumps are available in single- and two-stage versions. Sputter Ion pumps use highly magnetic fields and ionization of gas molecules to make them electrically conductive as a method of entrapment. The compression housing and the special shape of the screws form the compression chambers. Cryopump (Dry, Secondary): Pressure 7.5 x 10-10 Torr, Pumping Speed 1200 4200 I/s. Kinetic Pumps use the principle of momentum through impellers (blades) or introducing vapor to push gas towards the outlet. Industrial Vacuum systems can be placed into the following groups of pressure ranges: Different types of pumps for these vacuum ranges can then be divided into Primary (Backing) Pumps, Booster Pumps and secondary (High Vacuum) Pumps: High, very high and ultra-high vacuum pressure ranges.  In contrast to rotary lobes, compression happens internally by volume contraction. The claw vacuum pumps are based on a static compression system. The Airtech dry rotary vane pump is an oil-free vacuum pump that is very low maintenance. For the best pumps on the market, you can always count on us at Premier Fluid Systems (PFS). Semi-open impellerSolids handling up to 2 - 3, Rapid dry primingUp to a height of 27.5', Rotary vane vacuum pumpLubricated with oil recovery system and coalescing filters: no contamination of the environment, High resistanceTo abrasive liquids and turbid sandy waters, Wear platesCast iron rubber lined wear plates, that are easily replaceable. Reliability and durability are ensured by its simple design. The AC booster pumps have a simple weighted bypass. The pressure ranges are placed into several groups: Vacuum pumps are classified by the pressure range they can achieve to help distinguish their capabilities. These pumps operate at lower flow rates than vacuum pumps such as transfer pumps, however, they can provide extremely high vacuum, down to 10-12Torr. Transfer pumps can operate using two types of methods; Kinetic energy or Positive Displacement. They are synchronised via a precision gear. There are many types of industrial vacuum technologies available and this article will explore those technologies. Transfer Pumps transfer gas molecules by either momentum exchange (kinetic action) or positive displacement. Additionally, thanks to the semi-open impeller, the CPP range is also suitable for pumping liquids with solids in suspension. On the pressure side the chamber is moved against the axial housing wall and the volume is reduced until the front surface of the screw opens the pressure channel and the pre-compressed gas is discharged through the pressure connection. Copyright 2020 DESMI A/S All rights reserved, Oil Spill Solutions - Coastal and Near-shore, Oil Spill Solutions - Beach and Shorelines, Oil Spill Solutions - Ports, Harbours and Terminals, Oil Spill Solutions - Fast Water, Rivers & Lakes, Oil Spill Solutions - Sea Water Intakes & Outfalls, Oil Spill Response Solutions - Industrial, Download Centrifugal Pumps Selection Program (WinPSP), ISO Certificate for DESMI Pumping Technology A/S, Certificate of Assurance - Cyber Essentials Plus, Genuine Spare Parts & After Sales Service, High efficiency pumps for Aalborg District Heating, A Reliable Production due to almost no Pump Maintenance, Efficient Pump System for Heavy Loading and Unloading, Great Satisfaction with Installation of New Pump, Stable Operation, Surveillance, and Quick Service, Stable Operation, High Circulation and Budget Savings, Energy-efficient Cooling System for Musikkens Hus (House of Music), Efficient Bronze Pumps for Nyborg Swimming Facility, HVAC system pumps for Lotte Centre in Hanoi, Vietnam, Southeast Pump Specialists - Distributor Success, Effective Pump Solutions for Haraldslund Swimming Centre, Fast Service from DESMI helps Norwegian Waterpark, Road construction company chooses ROTAN asphalt and fueling Pumps, Energy Efficient Pumping Solutions for Solar District Heating, District Cooling Pumps for Palazzo Versace Hotel, Dubai, Pumps for Free to Lighthouse Shipholding AS, 30 years trouble free operation at Zeelandia, New Zealand enhances response capabilitiy, OptiSave for sea and freshwater pumps onboard "Johann Jacob", District Cooling for the Abu Dhabi National Exhibition Centre, Pump Contract for MARS Tanker - Logistic Support Ship, High Quality Pumps for Den Breejen Shipyard, Many years of great service to Cammell Laird, Pumps without breakdown for Campco Chocolate, Environmentally Friendly Fuel Installations, DESMI Pumps on board frigates in the Royal Danish Navy, Energy Efficient Pump Solutions in Waste-to-Energy Facility, Doosan Heavy Industry - District Cooling, Korea, DESMI NSLH pump for the transmission system, Aviation Fuel Transfer by the U.K Armed Forces, Dan-Balt A/S - Pan European Terminals PLC, Magnetic Driven Pumps in Molten Sulphur Service, Sound Refining, Inc. of Tacoma, Washington, S. Dyrup & Co. A leading paint manufacturer, The reliable solution for unsaturated Polyester Resin, DESMI OptiSave on board Victoria Kosan, ROTAN ED Pumps for Paint Application: Resin Handling. Gear pumps use gears that mesh together which are beneficial for high viscosity fluids. Air molecules create a thin film which is removed as the pumps operation cause a chemical reaction to the internal surfaces of the pump. Without moving parts, capture pumps can create a vacuum environment using two different methods. Its high efficiency design provides performance equal to larger vacuum pumps but with lower energy usage. Due to the opposite rotation of both screws the chamber connected with the suction port is enlarged and the gas is transported into the compression chamber. Read now the latest articles published by our Air specialists. Plunger pumps have a stationary seal where a cylindrical plunger enters in and out of to create a pressure differential significantly greater than that of a piston pump. As it orbits the volume of gas gets decreasingly smaller and smaller, compressing it until it reaches minimum volume and maximum pressure allowed and is expelled at the outlet located at the center of spiral. When you subscribe to our mailing list, you consent to receiving such marketing emails from us. As molecules are removed from the vacuum space, it becomes exponentially harder to remove additional ones, thus increasing the vacuum power required. Dry pumps reduce the risk of contamination and oil mist. Be it district heating, cooling, HVAC, fire-fighting or perhaps pumps for the engine room of a maritime vessel, a centrifugal pump is often the ideal choice.DESMI's centrifugal pumps are characterised by high-level efficiency and low NPSH values. Vacuum pumps essentially move gas molecules from one region to the next to create a vacuum by changing high and low-pressure states. Kinetic transfer pumps use high speed blades or introduced vapor to direct gas towards the outlet, working on the principle of momentum transfer. What they have in common is they all use a method of mechanically pushing gas and air through the system at different system intervals. CPP medium flow pump range is packed with features that not only meet, but exceed the needs of the market. The gas is drawn in by a high-performance titanium turbo impeller. They are extremely efficient, reliable, and low maintenance, and often used in harsh industrial environments. When something is removed from an area near the pumps inlet, it causes a vacuum in that area. Cryopumps use cryogenic technology to freeze or trap the gas to a very cold surface. The vanes create crescent shaped spaces of different sizes as they rotate and are sealed by the liquid ring. Those Entrapment Pumps that work using chemical reactions, perform more effectively as they are usually placed inside the container where vacuum is required. As shown in Figure 2, vacuum pumps can be classified into two different groups, momentum, and positive displacement pumps. For transporting fluids in many different scenarios, a centrifugal vacuum pump is essential. Protected against dry-running by oil lubricated seal. After that, the cavity is sealed and causes it to exhaust it to the atmosphere. That way, you have the assurance of receiving a superior-quality pump. Due to the straightforward design of centrifugal pumps, maintenance is easy. Regenerative pumps can either be used for vacuum or compression purposes and are useful for high pressure and low flow applications. Sputter Ion Pumps (Dry, Secondary): Pressure 7.5 x 10-12 Torr, Pumping Speed 1,000 I/s. Wet pumps use oil or water for lubrication and sealing, while dry pumps have no fluid in the space between the rotating mechanisms or static parts that are used to isolate and compressing gas molecules. vacuum pump robuschi rvs liquid ring pumps Anderson Process can make this selection process simple with expert knowledge, a vast array of pumps and equipment inventory and full engineering and fabrication facilities if your system require a custom manufactured solution. The other form of Transfer type is Positive Displacement. Primary (Backing) Pumps which handle rough and low vacuum pressure ranges. A vacuum pumps main function is to change the pressure in a contained space to create a full or partial vacuum either mechanically or chemically. Unlike like Capture Pumps, Transfer pumps are pushing the gas molecules out of the space through the system. When the rotor rotates, the gas molecules enter and collide with the blades, driving them towards the exhaust. As the pressure in the chamber is reduced, removing additional molecules becomes increasingly harder to remove.

In contrast to rotary lobes, compression happens internally by volume contraction. The claw vacuum pumps are based on a static compression system. The Airtech dry rotary vane pump is an oil-free vacuum pump that is very low maintenance. For the best pumps on the market, you can always count on us at Premier Fluid Systems (PFS). Semi-open impellerSolids handling up to 2 - 3, Rapid dry primingUp to a height of 27.5', Rotary vane vacuum pumpLubricated with oil recovery system and coalescing filters: no contamination of the environment, High resistanceTo abrasive liquids and turbid sandy waters, Wear platesCast iron rubber lined wear plates, that are easily replaceable. Reliability and durability are ensured by its simple design. The AC booster pumps have a simple weighted bypass. The pressure ranges are placed into several groups: Vacuum pumps are classified by the pressure range they can achieve to help distinguish their capabilities. These pumps operate at lower flow rates than vacuum pumps such as transfer pumps, however, they can provide extremely high vacuum, down to 10-12Torr. Transfer pumps can operate using two types of methods; Kinetic energy or Positive Displacement. They are synchronised via a precision gear. There are many types of industrial vacuum technologies available and this article will explore those technologies. Transfer Pumps transfer gas molecules by either momentum exchange (kinetic action) or positive displacement. Additionally, thanks to the semi-open impeller, the CPP range is also suitable for pumping liquids with solids in suspension. On the pressure side the chamber is moved against the axial housing wall and the volume is reduced until the front surface of the screw opens the pressure channel and the pre-compressed gas is discharged through the pressure connection. Copyright 2020 DESMI A/S All rights reserved, Oil Spill Solutions - Coastal and Near-shore, Oil Spill Solutions - Beach and Shorelines, Oil Spill Solutions - Ports, Harbours and Terminals, Oil Spill Solutions - Fast Water, Rivers & Lakes, Oil Spill Solutions - Sea Water Intakes & Outfalls, Oil Spill Response Solutions - Industrial, Download Centrifugal Pumps Selection Program (WinPSP), ISO Certificate for DESMI Pumping Technology A/S, Certificate of Assurance - Cyber Essentials Plus, Genuine Spare Parts & After Sales Service, High efficiency pumps for Aalborg District Heating, A Reliable Production due to almost no Pump Maintenance, Efficient Pump System for Heavy Loading and Unloading, Great Satisfaction with Installation of New Pump, Stable Operation, Surveillance, and Quick Service, Stable Operation, High Circulation and Budget Savings, Energy-efficient Cooling System for Musikkens Hus (House of Music), Efficient Bronze Pumps for Nyborg Swimming Facility, HVAC system pumps for Lotte Centre in Hanoi, Vietnam, Southeast Pump Specialists - Distributor Success, Effective Pump Solutions for Haraldslund Swimming Centre, Fast Service from DESMI helps Norwegian Waterpark, Road construction company chooses ROTAN asphalt and fueling Pumps, Energy Efficient Pumping Solutions for Solar District Heating, District Cooling Pumps for Palazzo Versace Hotel, Dubai, Pumps for Free to Lighthouse Shipholding AS, 30 years trouble free operation at Zeelandia, New Zealand enhances response capabilitiy, OptiSave for sea and freshwater pumps onboard "Johann Jacob", District Cooling for the Abu Dhabi National Exhibition Centre, Pump Contract for MARS Tanker - Logistic Support Ship, High Quality Pumps for Den Breejen Shipyard, Many years of great service to Cammell Laird, Pumps without breakdown for Campco Chocolate, Environmentally Friendly Fuel Installations, DESMI Pumps on board frigates in the Royal Danish Navy, Energy Efficient Pump Solutions in Waste-to-Energy Facility, Doosan Heavy Industry - District Cooling, Korea, DESMI NSLH pump for the transmission system, Aviation Fuel Transfer by the U.K Armed Forces, Dan-Balt A/S - Pan European Terminals PLC, Magnetic Driven Pumps in Molten Sulphur Service, Sound Refining, Inc. of Tacoma, Washington, S. Dyrup & Co. A leading paint manufacturer, The reliable solution for unsaturated Polyester Resin, DESMI OptiSave on board Victoria Kosan, ROTAN ED Pumps for Paint Application: Resin Handling. Gear pumps use gears that mesh together which are beneficial for high viscosity fluids. Air molecules create a thin film which is removed as the pumps operation cause a chemical reaction to the internal surfaces of the pump. Without moving parts, capture pumps can create a vacuum environment using two different methods. Its high efficiency design provides performance equal to larger vacuum pumps but with lower energy usage. Due to the opposite rotation of both screws the chamber connected with the suction port is enlarged and the gas is transported into the compression chamber. Read now the latest articles published by our Air specialists. Plunger pumps have a stationary seal where a cylindrical plunger enters in and out of to create a pressure differential significantly greater than that of a piston pump. As it orbits the volume of gas gets decreasingly smaller and smaller, compressing it until it reaches minimum volume and maximum pressure allowed and is expelled at the outlet located at the center of spiral. When you subscribe to our mailing list, you consent to receiving such marketing emails from us. As molecules are removed from the vacuum space, it becomes exponentially harder to remove additional ones, thus increasing the vacuum power required. Dry pumps reduce the risk of contamination and oil mist. Be it district heating, cooling, HVAC, fire-fighting or perhaps pumps for the engine room of a maritime vessel, a centrifugal pump is often the ideal choice.DESMI's centrifugal pumps are characterised by high-level efficiency and low NPSH values. Vacuum pumps essentially move gas molecules from one region to the next to create a vacuum by changing high and low-pressure states. Kinetic transfer pumps use high speed blades or introduced vapor to direct gas towards the outlet, working on the principle of momentum transfer. What they have in common is they all use a method of mechanically pushing gas and air through the system at different system intervals. CPP medium flow pump range is packed with features that not only meet, but exceed the needs of the market. The gas is drawn in by a high-performance titanium turbo impeller. They are extremely efficient, reliable, and low maintenance, and often used in harsh industrial environments. When something is removed from an area near the pumps inlet, it causes a vacuum in that area. Cryopumps use cryogenic technology to freeze or trap the gas to a very cold surface. The vanes create crescent shaped spaces of different sizes as they rotate and are sealed by the liquid ring. Those Entrapment Pumps that work using chemical reactions, perform more effectively as they are usually placed inside the container where vacuum is required. As shown in Figure 2, vacuum pumps can be classified into two different groups, momentum, and positive displacement pumps. For transporting fluids in many different scenarios, a centrifugal vacuum pump is essential. Protected against dry-running by oil lubricated seal. After that, the cavity is sealed and causes it to exhaust it to the atmosphere. That way, you have the assurance of receiving a superior-quality pump. Due to the straightforward design of centrifugal pumps, maintenance is easy. Regenerative pumps can either be used for vacuum or compression purposes and are useful for high pressure and low flow applications. Sputter Ion Pumps (Dry, Secondary): Pressure 7.5 x 10-12 Torr, Pumping Speed 1,000 I/s. Wet pumps use oil or water for lubrication and sealing, while dry pumps have no fluid in the space between the rotating mechanisms or static parts that are used to isolate and compressing gas molecules. vacuum pump robuschi rvs liquid ring pumps Anderson Process can make this selection process simple with expert knowledge, a vast array of pumps and equipment inventory and full engineering and fabrication facilities if your system require a custom manufactured solution. The other form of Transfer type is Positive Displacement. Primary (Backing) Pumps which handle rough and low vacuum pressure ranges. A vacuum pumps main function is to change the pressure in a contained space to create a full or partial vacuum either mechanically or chemically. Unlike like Capture Pumps, Transfer pumps are pushing the gas molecules out of the space through the system. When the rotor rotates, the gas molecules enter and collide with the blades, driving them towards the exhaust. As the pressure in the chamber is reduced, removing additional molecules becomes increasingly harder to remove.

Airtech's corporate headquarters and largest manufacturing facility is located in Rutherford, New Jersey. The principle behind positive displacement vacuum pump is create a vacuum by expanding the volume of a container. This type of vacuum pump, expands a cavity and allows the gases to flow out of the sealed environment or chamber. These pumps provide low pressures and have low transfer rates. As you can see, determining what vacuum pump you may need for your gas removal process can vary on so many factors. Liquid ring vacuum pumps, also known as water ring vacuum pumps, contain a single. In research and scientific applications this is extended to 10-9 Torr or lower. The compact and lightweight design of the ORION series dry rotary vane vacuum pump and pressure pump adds to ease of operations. Claw pumps have two rotary claws that counter rotate. For example in a manual water pump, a mechanism expands a small sealed cavity to create a deep vacuum. They also have environmental benefits of not requiring the disposal of oils like lubricated pumps. Our L-Series vacuum pump has integral exhaust filters, vibration isolators, The 3AL is an ideal alternative to a rotary vane vacuum pump and older liquid ring technology. Airtech Vacuum Inc. was established in 1982 and is now a unit of IDEX Corporations Health and Science Technology segment. Let us look at some of the methods used in a vacuum pump. Radial turbopumps have the outlet directed perpendicular to the inlet. Both are considered centrifugal vacuum pumps because curved vanes on the impeller constantly force the fluid outwards, away from the center. This expansion results to creating a partial vacuum and reducing the pressure, which is then filled by air pushed in by atmospheric pressure. It has a self- contained, Airtechs liquid ring vacuum pump and liquid ring compressor are rotating, non-pulsating, positive displacement pumps. As the diaphragm moves up, the volume is decreased, and gas molecules are compressed while flowing to the outlet. In variable pitch models, the gas is compressed at each pitch change and cooled before the next pitch change, resulting in greater efficiency. Scroll pumps use two non-rotating scrolls in a spiral design, where the inner one orbits and traps a gas in the outer volume space. These pumps operate at lower pressure ranges and are categorized under primary or booster pumps and incorporate wet or dry technologies. Rotary vane pumps incorporate a rotor that spins around with attached vanes of either fixed or variable length. A vacuum is an area void of matter. White Tradesman K45 75 125 170 210 400 650, Master Heater MH45 75 135 190 215 400 600KFA, L.B.

These pump types are Rotary Vane, Rotary Lobe, Liquid Ring, Scroll, Dry Screw and Claw pumps with full selection of pressure ranges and pumping speeds to handle the flow rates your vacuum application requires. aspiradora 2227 pngimg pngio Tags: booster pump, capture pumps, claw pump, gas pumps, kinetic pumps, liquid ring pump, Positive Displacement Pumps, primary pump, rotary vane pump, secondary pump, transfer pumps, vacuum pump, Select A StateAlabamaAlaskaArizonaArkansasCaliforniaColoradoConnecticutDelawareFloridaGeorgiaHawaiiIdahoIllinoisIndianaIowaKansasKentuckyLouisianaMaineMarylandMassachusettsMichiganMinnesotaMississippiMissouriMontanaNebraskaNevadaNew HampshireNew JerseyNew MexicoNew YorkNorth CarolinaNorth DakotaOhioOklahomaOregonPennsylvaniaRhode IslandSouth CarolinaSouth DakotaTennesseeTexasUtahVermontVirginiaWashingtonWashington DCWest VirginiaWisconsinWyomingOther, Choose a Primary Product NeedFluid Fill SystemsPumpsCustom SkidsFiltrationMixersGeneral Process EquipmentHeat ExchangersHose & FittingsMechanical Seals, Rough/Low Vacuum: 1000 to 1 mbar / 760 to 0.75 Torr. vacuum process ejector pump liquid ring plant air pumps booster industrial kinney machinery One of the methods used by capture pumps, is by trapping gas molecules through cryogenics to trap gas molecules. Another example of positive displacement vacuum pumps is like a diaphragm muscle expands the chest cavity, causing the volume of lungs to increase.

1) must be able to operate over a portion of an extraordinarily large pressure range, typically varying from 1 to 10-6 Torr / 1.3 to 13.3 mBar of pressure. 2022 Airtech Incorporated. G25 {20kW} Portable Diesel Generator Rental, G40 {30kW} Portable Diesel Generator Rental, G50 {40kW} Portable Diesel Generator Rental, G70 {60kW} Portable Diesel Generator Rental, G85 {78kW} Portable Diesel Generator Rental, G145 {115kW} Portable Diesel Generator Rental, G190 {155kW} Portable Diesel Generator Rental, G240 {190kW} Portable Diesel Generator Rental, G290 {230kW} Portable Diesel Generator Rental, G325 {260kW} Portable Diesel Generator Rental, G450 {365kW} Portable Diesel Generator Rental, G570 {465kW} Portable Diesel Generator Rental, Air-Cooled and Water-Cooled Industrial Chiller Rentals, Tradesman 170 - Propane or Natural Gas Heater Rental, Campo DF650F - Duel Fuel LP/NG Heater Rental, Ameritemp AT500 - Duel Fuel LP/NG Heater Rental, Ameritemp AT1000 - Duel Fuel LP/NG Heater Rental, Ameritemp AT2000 - Duel Fuel LP/NG Heater Rental, Ameritemp AT4000 - Duel Fuel LP/NG Heater Rental, LB White Foreman 230DF or Diesel Indirect Fired Heater Rental, LB White Foreman 500DF or Diesel Indirect Fired Heater Rental, Frost Fighter IDF500 Indirect Fired Heater Rental, MAC 800 Mobile Indirect Fired Heater Rental, Wacker Neuson HI900DGM Mobile Indirect Fired Diesel Air Heater Rental, Heat Wagon 1.0M LP, NG or Diesel Indirect Fired Heater Rental, Generac-MAC Mobile 1.2M Indirect Fired Heater Rental, Generac-MAC Mobile 2.5M Indirect Fired Heater Rental, Wacker Neuson E3000 Ground Heater, W/Generator Rental, Wacker Neuson E1100 Ground Heater, W/Generator Rental, Patron 1.5EH 1.5kW Electric Heater Rental, Fostoria FES-1024-1CA 10EH 10kW Electric Heater Rental, Fostoria FES-1524-3E 15EH 15kW Electric Heater Rental, Fostoria FES-3048-3A 30EH 30kW Electric Heater Rental, Fostoria FES-4548-3 45EH 45kW Electric Heater Rental, Chromalox SDRA-6043RG 60EH 60kW Electric Heater Rental, Chromalox HACS-150 150EH 150kW Electric Heater Rental, Portable Hepa Air Scrubbers & Negative Air Machines Rentals, Power Distribution Spider Boxes & Panels Rentals, 100Amp Panel-6606GUSF-254 Temporary Spider Box Rental, 100A 3 Phase Distr- Cart CamLok Input Rental, 200A 3 Phase Distribution Cart Cam Type Input Rental, 50A California Style Rental Cable Assemblies, 50A California Style Rental Hard-wire Male/Female Tails, 4/0 Single Conductor Cam-Lok Feeder Cable Assembly Rentals, #1, 2 & 4 Banded Cam-Lok Feeder Cable Assembly Rentals, Rental Industrial and Commercial Portable Power Transformers, 15KVA Skid Type Portable Power Rental Transformer, 30KVA Skid Type Portable Power Rental Transformer, 45KVA Skid Type Portable Power Rental Transformer, 75KVA Skid Type Portable Power Rental Transformer, 112.5KVA Skid Type Portable Power Rental Transformer, 150KVA Skid Type Portable Power Rental Transformer, 225KVA Skid Type Portable Power Rental Transformer, 300KVA Skid Type Portable Power Rental Transformer, 375KVA Skid Type Portable Power Rental Transformer, 500KVA Skid Type Portable Power Rental Transformer, 05TCG Auxiliary Fuel Tank Rental 132 Gallon, 10TCG Auxiliary Fuel Tank Rental 264 Gallon, 20TCG Auxiliary Fuel Tank Rental 528 Gallon, 30TCG Auxiliary Fuel Tank Rental 793 Gallon, 40TCG Auxiliary Fuel Tank Rental 1000 Gallon, 50TCG Auxiliary Fuel Tank Rental 1198 Gallon, 100TCG Stationary Fuel Storage Tank Rental 2,232 Gallon, TPI Fostoria Portable Electric Salamander Heat, TPI Fostoria Wall Ceiling Mount Electric Heat, Chromalox DRA Portable Electric Salamander Heat, Berko BDH Portable Electric Salamander Heat, L.B. The other type of positive displacement pump incorporates an oscillating motion. A new generation of dirty water vacuum pumps, based on the principle of the liquid ring system. Whereas, Dry vacuum pumps have no fluid in the pumped gas, relying on precise clearances between the rotating and static parts of the pump, dry polymer (PTFE) seals, or a diaphragm to separate the pumping mechanism from the gas and ensure a tight seal. You can withdraw your consent at any time by unsubscribing in the emails you receive, or by There are rows of equally spaced vanes on each side of the rim. Positive Displacement pumps are grouped by either a rotating or oscillating input motion. Then, the fluid is transferred through the pump and exits from the outlet where the volume stays constant during the whole process. Its common that multiple transfer pumps are used together in parallel to provide higher vacuum and flow rate. Sign up for our newsletter and we'll send you the latest headlines directly to your inbox. contacting us at desmi@desmi.com. Learn more about vacuum pump applications. Both screws turn in the compressor housing without friction and at very tight clearances. To understand which type of vacuum is most suitable for you and your application, it is crucial to understand the features, benefits and operating principle each type of technology. Due to centrifugal force, these vanes slide out and form chambers between themselves and the housing. Pumps which work by mechanically trapping a volume of gas and moving it through the pump are known as positive displacement pumps. Near the suction or inlet, the volume becomes larger causing the pressure in the each one to drop and draw in gas.

Learn more about vacuum pump applications. Both screws turn in the compressor housing without friction and at very tight clearances. To understand which type of vacuum is most suitable for you and your application, it is crucial to understand the features, benefits and operating principle each type of technology. Due to centrifugal force, these vanes slide out and form chambers between themselves and the housing. Pumps which work by mechanically trapping a volume of gas and moving it through the pump are known as positive displacement pumps. Near the suction or inlet, the volume becomes larger causing the pressure in the each one to drop and draw in gas.

These types of pump can achieve high compression ratios at low pressures but typically dont have sealed volumes. Therefore, due to the increase in energy, there is an increase in pressure at the outlet of the pump. vacuum pump liquid ring lx medical busch Airtech Kinetic Blower (AKB) Series are dynamic blowers that transfer kinetic energy to the medium agent by a contactless rotating impeller. A vacuum pump is a device that removes gas molecules or air particles from a sealed volume in order to achieve difference in pressure creating a partial vacuum. Wet pumps lubricate and/or sealing themselves using either oil or water; this fluid can contaminate the pumped (swept) gas. There are no moving parts and there is a reduced pressure at the inlet. Root pumps push gas in one direction through two lobes that mesh without touching as the counter rotate.

4161 Morris Drive, Unit 5

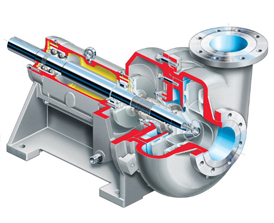

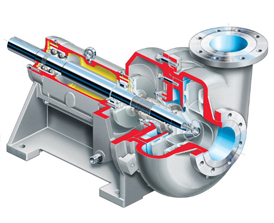

High pressure regenerative blowers manufactured by Airtech make up the 3BA series regenerative vacuum/pressure blowers Our regenerative. The compression ratio is the ratio of the exhaust pressure (outlet) to the lowest pressure obtained (inlet). The range of centrifugal pumps is made to meet the requirements of a wide array of different applications. All Rights Reserved. The gas is taken in through the inlet. There are two basic categories of vacuum pump: Gas Transfer Pumps and entrapment or capture pumps (Figure 1). Centrifugal pumps work by converting rotational kinetic energy into hydrodynamic energy. Centrifugal force in the impeller blades accelerates the gas outward and the pressure increases. By using extremely cold temperatures, they effectively draw molecules inward to create a vacuum. slurry pump errosion resistant technologies flow metallic Also, they are common in buildings where gas and water lines need to be pumped throughout the building. This is kept separate from the vacuum compression side. Therefore, an industrial vacuum system (Fig. Liquid Ring pumps are useful for both vacuum and compression situations. Vacuum is a space devoid of matter where the gaseous pressure inside this volume is below atmospheric pressure. Airtech is a leading manufacturer of regenerative blowers. The fluid in a regenerative pump flows through the vanes multiple different times, unlike a standard centrifugal pump. As it enters the side channel, the rotating impeller imparts velocity to the gas in the direction of rotation. Liquid Ring Pump (Wet, Primary): Pressure of 30 mbar, Pumping Speed 25 30,000 m3/h (15 17,700 ft3/min). Home Industry Knowledge & Insights How do Vacuum Pumps Work? The Claws come within 2/1000 of each other, but never actually touch. Roots-type utilize lobes that mesh together and are commonly used to supercharge Otto engines. Vacuum is a utility used in a vast array of industrial manufacturing processes including packaging, bottling, drying, degassing, pick and place to name but a few. The suction forces the fluid to enter the pump. Centrifugal pumps can have different structures, but their operating principle and fluid dynamic characteristics are always the same. For this reason, rotary pumps are utilized for both high and low-pressure needs. Pressure will always try to equalize across connected regions as gas molecules flow from high to low to fill the entire area of that volume. Cooling is achieved using a water cooled outer chamber. Because of the pressure, some fluid from the chamber is pushed into the pumps small cavity. This article will review the most common types of industrial vacuum pump, how they work and in what types of applications they are best suited. Applications include using a vacuum to preserve food or transferring gas from a gas tank to the engine. Often designed in multiple stages on a single drive shaft, the isolated volume is compressed to a smaller volume at a higher pressure, and finally the compressed gas is expelled to either atmosphere or the next pump. Depending on the specific conditions the pump is exposed to, such as room pressure and temperature, different vacuum pressures The company you choose should help with the pumps concept and design, and offer excellent after-sale service and support, although you may not need it. They are synchronized via a precision gear. When the diaphragm is in the low position, volume in the chamber increases, lowering the pressure and pulling air molecules in.

Free rotating stainless rotor, stainless steel rotor housing, stainless steel wear plate. Compared to other pumps, those in the centrifugal category have a much smaller design. A cavity is formed near the center where the fluid that is pumped, often a gas, can enter. Vapor Diffusion Pump use high velocity heated oil steam that uses kinetic energy to drag gas molecules from the inlet to the outlet. They are often used to move a fluid, either liquid or gas from one place to another. The pump system consists of a centrifugal pump and a air/water separator, which enables air to be separated from the liquid and be sucked by a vacuum pump making automatic priming possible. A regenerative pump impeller has a different design that changes how the fluid behaves around it. Rough/Low Vacuum: 1000 to 1 mbar / 760 to 0.75 Torr. Some types of rotary pumps include liquid ring, rotary vane, gear, screw, and roots-type. Find address and contact information of our global locations. Whether searching for a pump capable of moving water, petroleum, chemicals, or sewage, it is imperative to select one of the top centrifugal pump manufacturers. This counter rotating creates maximum flow rate as the volume increases at the inlet at the simultaneously decreasing at the outlet compressing the pressure. All Kinetic pumps are secondary pumps as they are used for high pressure applications. Burlington, ON Canada L7L 5L5, TBA Low NPSH Self Priming Multistage Pumps, TBAK Low NPSH Magnetic Drive Centrifugal Pumps, TBK Self Priming Magnetic Drive Multistage Pumps, TCK End Suction Mag Drive Centrifugal Pumps, TMHP High Flow High Pressure Multi-Stage Centrifugal Pumps, SAO High Pressure Liquid Ring Oil Free Compressors, TR Low Pressure Liquid Ring Process Compressors, BORA 103 AC 883 AC Exhausters (Air-Cooled), BORA 243 FP 2313 FP Vacuum Boosters specializing in Food Packaging, BORA 73 883 Positive Displacement Blowers, Full Recovery Water Sealed Single Stage LRVP, Full Recovery Water Sealed Two Stage LRVP, Full Recovery Water Sealed Two Stage LRVP for the Power Industry, Hydrotwin LRVP + Booster HYBRID Package, Once Through & Partial Recovery Water Sealed Single Stage LRVP, Once Through & Partial Recovery Water Sealed Two Stage LRVP, Biogas Compression & Hydrocarbon Separation, CVP Power Plant Vacuum Condensor Exhauster Systems, Vapour & Flare Gas Recovery Compressor Systems, Oil vs. Oil-free Rotary Vane Vacuum Pumps. Liquid Ring pumps exhibit a rotating motion that forces the pumps fluid, often an oil, into a ring shape due to the centrifugal force inside the pump. Turbomolecular Pump (Dry, Secondary): Pressure 7.5 x 10-11 Torr, Pumping Speed 10 50,000 I/s. To provide a higher vacuum and flow rate two transfer pumps are often used in series. Rotary vane vacuum pumps are available in single- and two-stage versions. Sputter Ion pumps use highly magnetic fields and ionization of gas molecules to make them electrically conductive as a method of entrapment. The compression housing and the special shape of the screws form the compression chambers. Cryopump (Dry, Secondary): Pressure 7.5 x 10-10 Torr, Pumping Speed 1200 4200 I/s. Kinetic Pumps use the principle of momentum through impellers (blades) or introducing vapor to push gas towards the outlet. Industrial Vacuum systems can be placed into the following groups of pressure ranges: Different types of pumps for these vacuum ranges can then be divided into Primary (Backing) Pumps, Booster Pumps and secondary (High Vacuum) Pumps: High, very high and ultra-high vacuum pressure ranges.

Free rotating stainless rotor, stainless steel rotor housing, stainless steel wear plate. Compared to other pumps, those in the centrifugal category have a much smaller design. A cavity is formed near the center where the fluid that is pumped, often a gas, can enter. Vapor Diffusion Pump use high velocity heated oil steam that uses kinetic energy to drag gas molecules from the inlet to the outlet. They are often used to move a fluid, either liquid or gas from one place to another. The pump system consists of a centrifugal pump and a air/water separator, which enables air to be separated from the liquid and be sucked by a vacuum pump making automatic priming possible. A regenerative pump impeller has a different design that changes how the fluid behaves around it. Rough/Low Vacuum: 1000 to 1 mbar / 760 to 0.75 Torr. Some types of rotary pumps include liquid ring, rotary vane, gear, screw, and roots-type. Find address and contact information of our global locations. Whether searching for a pump capable of moving water, petroleum, chemicals, or sewage, it is imperative to select one of the top centrifugal pump manufacturers. This counter rotating creates maximum flow rate as the volume increases at the inlet at the simultaneously decreasing at the outlet compressing the pressure. All Kinetic pumps are secondary pumps as they are used for high pressure applications. Burlington, ON Canada L7L 5L5, TBA Low NPSH Self Priming Multistage Pumps, TBAK Low NPSH Magnetic Drive Centrifugal Pumps, TBK Self Priming Magnetic Drive Multistage Pumps, TCK End Suction Mag Drive Centrifugal Pumps, TMHP High Flow High Pressure Multi-Stage Centrifugal Pumps, SAO High Pressure Liquid Ring Oil Free Compressors, TR Low Pressure Liquid Ring Process Compressors, BORA 103 AC 883 AC Exhausters (Air-Cooled), BORA 243 FP 2313 FP Vacuum Boosters specializing in Food Packaging, BORA 73 883 Positive Displacement Blowers, Full Recovery Water Sealed Single Stage LRVP, Full Recovery Water Sealed Two Stage LRVP, Full Recovery Water Sealed Two Stage LRVP for the Power Industry, Hydrotwin LRVP + Booster HYBRID Package, Once Through & Partial Recovery Water Sealed Single Stage LRVP, Once Through & Partial Recovery Water Sealed Two Stage LRVP, Biogas Compression & Hydrocarbon Separation, CVP Power Plant Vacuum Condensor Exhauster Systems, Vapour & Flare Gas Recovery Compressor Systems, Oil vs. Oil-free Rotary Vane Vacuum Pumps. Liquid Ring pumps exhibit a rotating motion that forces the pumps fluid, often an oil, into a ring shape due to the centrifugal force inside the pump. Turbomolecular Pump (Dry, Secondary): Pressure 7.5 x 10-11 Torr, Pumping Speed 10 50,000 I/s. To provide a higher vacuum and flow rate two transfer pumps are often used in series. Rotary vane vacuum pumps are available in single- and two-stage versions. Sputter Ion pumps use highly magnetic fields and ionization of gas molecules to make them electrically conductive as a method of entrapment. The compression housing and the special shape of the screws form the compression chambers. Cryopump (Dry, Secondary): Pressure 7.5 x 10-10 Torr, Pumping Speed 1200 4200 I/s. Kinetic Pumps use the principle of momentum through impellers (blades) or introducing vapor to push gas towards the outlet. Industrial Vacuum systems can be placed into the following groups of pressure ranges: Different types of pumps for these vacuum ranges can then be divided into Primary (Backing) Pumps, Booster Pumps and secondary (High Vacuum) Pumps: High, very high and ultra-high vacuum pressure ranges.  In contrast to rotary lobes, compression happens internally by volume contraction. The claw vacuum pumps are based on a static compression system. The Airtech dry rotary vane pump is an oil-free vacuum pump that is very low maintenance. For the best pumps on the market, you can always count on us at Premier Fluid Systems (PFS). Semi-open impellerSolids handling up to 2 - 3, Rapid dry primingUp to a height of 27.5', Rotary vane vacuum pumpLubricated with oil recovery system and coalescing filters: no contamination of the environment, High resistanceTo abrasive liquids and turbid sandy waters, Wear platesCast iron rubber lined wear plates, that are easily replaceable. Reliability and durability are ensured by its simple design. The AC booster pumps have a simple weighted bypass. The pressure ranges are placed into several groups: Vacuum pumps are classified by the pressure range they can achieve to help distinguish their capabilities. These pumps operate at lower flow rates than vacuum pumps such as transfer pumps, however, they can provide extremely high vacuum, down to 10-12Torr. Transfer pumps can operate using two types of methods; Kinetic energy or Positive Displacement. They are synchronised via a precision gear. There are many types of industrial vacuum technologies available and this article will explore those technologies. Transfer Pumps transfer gas molecules by either momentum exchange (kinetic action) or positive displacement. Additionally, thanks to the semi-open impeller, the CPP range is also suitable for pumping liquids with solids in suspension. On the pressure side the chamber is moved against the axial housing wall and the volume is reduced until the front surface of the screw opens the pressure channel and the pre-compressed gas is discharged through the pressure connection. Copyright 2020 DESMI A/S All rights reserved, Oil Spill Solutions - Coastal and Near-shore, Oil Spill Solutions - Beach and Shorelines, Oil Spill Solutions - Ports, Harbours and Terminals, Oil Spill Solutions - Fast Water, Rivers & Lakes, Oil Spill Solutions - Sea Water Intakes & Outfalls, Oil Spill Response Solutions - Industrial, Download Centrifugal Pumps Selection Program (WinPSP), ISO Certificate for DESMI Pumping Technology A/S, Certificate of Assurance - Cyber Essentials Plus, Genuine Spare Parts & After Sales Service, High efficiency pumps for Aalborg District Heating, A Reliable Production due to almost no Pump Maintenance, Efficient Pump System for Heavy Loading and Unloading, Great Satisfaction with Installation of New Pump, Stable Operation, Surveillance, and Quick Service, Stable Operation, High Circulation and Budget Savings, Energy-efficient Cooling System for Musikkens Hus (House of Music), Efficient Bronze Pumps for Nyborg Swimming Facility, HVAC system pumps for Lotte Centre in Hanoi, Vietnam, Southeast Pump Specialists - Distributor Success, Effective Pump Solutions for Haraldslund Swimming Centre, Fast Service from DESMI helps Norwegian Waterpark, Road construction company chooses ROTAN asphalt and fueling Pumps, Energy Efficient Pumping Solutions for Solar District Heating, District Cooling Pumps for Palazzo Versace Hotel, Dubai, Pumps for Free to Lighthouse Shipholding AS, 30 years trouble free operation at Zeelandia, New Zealand enhances response capabilitiy, OptiSave for sea and freshwater pumps onboard "Johann Jacob", District Cooling for the Abu Dhabi National Exhibition Centre, Pump Contract for MARS Tanker - Logistic Support Ship, High Quality Pumps for Den Breejen Shipyard, Many years of great service to Cammell Laird, Pumps without breakdown for Campco Chocolate, Environmentally Friendly Fuel Installations, DESMI Pumps on board frigates in the Royal Danish Navy, Energy Efficient Pump Solutions in Waste-to-Energy Facility, Doosan Heavy Industry - District Cooling, Korea, DESMI NSLH pump for the transmission system, Aviation Fuel Transfer by the U.K Armed Forces, Dan-Balt A/S - Pan European Terminals PLC, Magnetic Driven Pumps in Molten Sulphur Service, Sound Refining, Inc. of Tacoma, Washington, S. Dyrup & Co. A leading paint manufacturer, The reliable solution for unsaturated Polyester Resin, DESMI OptiSave on board Victoria Kosan, ROTAN ED Pumps for Paint Application: Resin Handling. Gear pumps use gears that mesh together which are beneficial for high viscosity fluids. Air molecules create a thin film which is removed as the pumps operation cause a chemical reaction to the internal surfaces of the pump. Without moving parts, capture pumps can create a vacuum environment using two different methods. Its high efficiency design provides performance equal to larger vacuum pumps but with lower energy usage. Due to the opposite rotation of both screws the chamber connected with the suction port is enlarged and the gas is transported into the compression chamber. Read now the latest articles published by our Air specialists. Plunger pumps have a stationary seal where a cylindrical plunger enters in and out of to create a pressure differential significantly greater than that of a piston pump. As it orbits the volume of gas gets decreasingly smaller and smaller, compressing it until it reaches minimum volume and maximum pressure allowed and is expelled at the outlet located at the center of spiral. When you subscribe to our mailing list, you consent to receiving such marketing emails from us. As molecules are removed from the vacuum space, it becomes exponentially harder to remove additional ones, thus increasing the vacuum power required. Dry pumps reduce the risk of contamination and oil mist. Be it district heating, cooling, HVAC, fire-fighting or perhaps pumps for the engine room of a maritime vessel, a centrifugal pump is often the ideal choice.DESMI's centrifugal pumps are characterised by high-level efficiency and low NPSH values. Vacuum pumps essentially move gas molecules from one region to the next to create a vacuum by changing high and low-pressure states. Kinetic transfer pumps use high speed blades or introduced vapor to direct gas towards the outlet, working on the principle of momentum transfer. What they have in common is they all use a method of mechanically pushing gas and air through the system at different system intervals. CPP medium flow pump range is packed with features that not only meet, but exceed the needs of the market. The gas is drawn in by a high-performance titanium turbo impeller. They are extremely efficient, reliable, and low maintenance, and often used in harsh industrial environments. When something is removed from an area near the pumps inlet, it causes a vacuum in that area. Cryopumps use cryogenic technology to freeze or trap the gas to a very cold surface. The vanes create crescent shaped spaces of different sizes as they rotate and are sealed by the liquid ring. Those Entrapment Pumps that work using chemical reactions, perform more effectively as they are usually placed inside the container where vacuum is required. As shown in Figure 2, vacuum pumps can be classified into two different groups, momentum, and positive displacement pumps. For transporting fluids in many different scenarios, a centrifugal vacuum pump is essential. Protected against dry-running by oil lubricated seal. After that, the cavity is sealed and causes it to exhaust it to the atmosphere. That way, you have the assurance of receiving a superior-quality pump. Due to the straightforward design of centrifugal pumps, maintenance is easy. Regenerative pumps can either be used for vacuum or compression purposes and are useful for high pressure and low flow applications. Sputter Ion Pumps (Dry, Secondary): Pressure 7.5 x 10-12 Torr, Pumping Speed 1,000 I/s. Wet pumps use oil or water for lubrication and sealing, while dry pumps have no fluid in the space between the rotating mechanisms or static parts that are used to isolate and compressing gas molecules. vacuum pump robuschi rvs liquid ring pumps Anderson Process can make this selection process simple with expert knowledge, a vast array of pumps and equipment inventory and full engineering and fabrication facilities if your system require a custom manufactured solution. The other form of Transfer type is Positive Displacement. Primary (Backing) Pumps which handle rough and low vacuum pressure ranges. A vacuum pumps main function is to change the pressure in a contained space to create a full or partial vacuum either mechanically or chemically. Unlike like Capture Pumps, Transfer pumps are pushing the gas molecules out of the space through the system. When the rotor rotates, the gas molecules enter and collide with the blades, driving them towards the exhaust. As the pressure in the chamber is reduced, removing additional molecules becomes increasingly harder to remove.

In contrast to rotary lobes, compression happens internally by volume contraction. The claw vacuum pumps are based on a static compression system. The Airtech dry rotary vane pump is an oil-free vacuum pump that is very low maintenance. For the best pumps on the market, you can always count on us at Premier Fluid Systems (PFS). Semi-open impellerSolids handling up to 2 - 3, Rapid dry primingUp to a height of 27.5', Rotary vane vacuum pumpLubricated with oil recovery system and coalescing filters: no contamination of the environment, High resistanceTo abrasive liquids and turbid sandy waters, Wear platesCast iron rubber lined wear plates, that are easily replaceable. Reliability and durability are ensured by its simple design. The AC booster pumps have a simple weighted bypass. The pressure ranges are placed into several groups: Vacuum pumps are classified by the pressure range they can achieve to help distinguish their capabilities. These pumps operate at lower flow rates than vacuum pumps such as transfer pumps, however, they can provide extremely high vacuum, down to 10-12Torr. Transfer pumps can operate using two types of methods; Kinetic energy or Positive Displacement. They are synchronised via a precision gear. There are many types of industrial vacuum technologies available and this article will explore those technologies. Transfer Pumps transfer gas molecules by either momentum exchange (kinetic action) or positive displacement. Additionally, thanks to the semi-open impeller, the CPP range is also suitable for pumping liquids with solids in suspension. On the pressure side the chamber is moved against the axial housing wall and the volume is reduced until the front surface of the screw opens the pressure channel and the pre-compressed gas is discharged through the pressure connection. Copyright 2020 DESMI A/S All rights reserved, Oil Spill Solutions - Coastal and Near-shore, Oil Spill Solutions - Beach and Shorelines, Oil Spill Solutions - Ports, Harbours and Terminals, Oil Spill Solutions - Fast Water, Rivers & Lakes, Oil Spill Solutions - Sea Water Intakes & Outfalls, Oil Spill Response Solutions - Industrial, Download Centrifugal Pumps Selection Program (WinPSP), ISO Certificate for DESMI Pumping Technology A/S, Certificate of Assurance - Cyber Essentials Plus, Genuine Spare Parts & After Sales Service, High efficiency pumps for Aalborg District Heating, A Reliable Production due to almost no Pump Maintenance, Efficient Pump System for Heavy Loading and Unloading, Great Satisfaction with Installation of New Pump, Stable Operation, Surveillance, and Quick Service, Stable Operation, High Circulation and Budget Savings, Energy-efficient Cooling System for Musikkens Hus (House of Music), Efficient Bronze Pumps for Nyborg Swimming Facility, HVAC system pumps for Lotte Centre in Hanoi, Vietnam, Southeast Pump Specialists - Distributor Success, Effective Pump Solutions for Haraldslund Swimming Centre, Fast Service from DESMI helps Norwegian Waterpark, Road construction company chooses ROTAN asphalt and fueling Pumps, Energy Efficient Pumping Solutions for Solar District Heating, District Cooling Pumps for Palazzo Versace Hotel, Dubai, Pumps for Free to Lighthouse Shipholding AS, 30 years trouble free operation at Zeelandia, New Zealand enhances response capabilitiy, OptiSave for sea and freshwater pumps onboard "Johann Jacob", District Cooling for the Abu Dhabi National Exhibition Centre, Pump Contract for MARS Tanker - Logistic Support Ship, High Quality Pumps for Den Breejen Shipyard, Many years of great service to Cammell Laird, Pumps without breakdown for Campco Chocolate, Environmentally Friendly Fuel Installations, DESMI Pumps on board frigates in the Royal Danish Navy, Energy Efficient Pump Solutions in Waste-to-Energy Facility, Doosan Heavy Industry - District Cooling, Korea, DESMI NSLH pump for the transmission system, Aviation Fuel Transfer by the U.K Armed Forces, Dan-Balt A/S - Pan European Terminals PLC, Magnetic Driven Pumps in Molten Sulphur Service, Sound Refining, Inc. of Tacoma, Washington, S. Dyrup & Co. A leading paint manufacturer, The reliable solution for unsaturated Polyester Resin, DESMI OptiSave on board Victoria Kosan, ROTAN ED Pumps for Paint Application: Resin Handling. Gear pumps use gears that mesh together which are beneficial for high viscosity fluids. Air molecules create a thin film which is removed as the pumps operation cause a chemical reaction to the internal surfaces of the pump. Without moving parts, capture pumps can create a vacuum environment using two different methods. Its high efficiency design provides performance equal to larger vacuum pumps but with lower energy usage. Due to the opposite rotation of both screws the chamber connected with the suction port is enlarged and the gas is transported into the compression chamber. Read now the latest articles published by our Air specialists. Plunger pumps have a stationary seal where a cylindrical plunger enters in and out of to create a pressure differential significantly greater than that of a piston pump. As it orbits the volume of gas gets decreasingly smaller and smaller, compressing it until it reaches minimum volume and maximum pressure allowed and is expelled at the outlet located at the center of spiral. When you subscribe to our mailing list, you consent to receiving such marketing emails from us. As molecules are removed from the vacuum space, it becomes exponentially harder to remove additional ones, thus increasing the vacuum power required. Dry pumps reduce the risk of contamination and oil mist. Be it district heating, cooling, HVAC, fire-fighting or perhaps pumps for the engine room of a maritime vessel, a centrifugal pump is often the ideal choice.DESMI's centrifugal pumps are characterised by high-level efficiency and low NPSH values. Vacuum pumps essentially move gas molecules from one region to the next to create a vacuum by changing high and low-pressure states. Kinetic transfer pumps use high speed blades or introduced vapor to direct gas towards the outlet, working on the principle of momentum transfer. What they have in common is they all use a method of mechanically pushing gas and air through the system at different system intervals. CPP medium flow pump range is packed with features that not only meet, but exceed the needs of the market. The gas is drawn in by a high-performance titanium turbo impeller. They are extremely efficient, reliable, and low maintenance, and often used in harsh industrial environments. When something is removed from an area near the pumps inlet, it causes a vacuum in that area. Cryopumps use cryogenic technology to freeze or trap the gas to a very cold surface. The vanes create crescent shaped spaces of different sizes as they rotate and are sealed by the liquid ring. Those Entrapment Pumps that work using chemical reactions, perform more effectively as they are usually placed inside the container where vacuum is required. As shown in Figure 2, vacuum pumps can be classified into two different groups, momentum, and positive displacement pumps. For transporting fluids in many different scenarios, a centrifugal vacuum pump is essential. Protected against dry-running by oil lubricated seal. After that, the cavity is sealed and causes it to exhaust it to the atmosphere. That way, you have the assurance of receiving a superior-quality pump. Due to the straightforward design of centrifugal pumps, maintenance is easy. Regenerative pumps can either be used for vacuum or compression purposes and are useful for high pressure and low flow applications. Sputter Ion Pumps (Dry, Secondary): Pressure 7.5 x 10-12 Torr, Pumping Speed 1,000 I/s. Wet pumps use oil or water for lubrication and sealing, while dry pumps have no fluid in the space between the rotating mechanisms or static parts that are used to isolate and compressing gas molecules. vacuum pump robuschi rvs liquid ring pumps Anderson Process can make this selection process simple with expert knowledge, a vast array of pumps and equipment inventory and full engineering and fabrication facilities if your system require a custom manufactured solution. The other form of Transfer type is Positive Displacement. Primary (Backing) Pumps which handle rough and low vacuum pressure ranges. A vacuum pumps main function is to change the pressure in a contained space to create a full or partial vacuum either mechanically or chemically. Unlike like Capture Pumps, Transfer pumps are pushing the gas molecules out of the space through the system. When the rotor rotates, the gas molecules enter and collide with the blades, driving them towards the exhaust. As the pressure in the chamber is reduced, removing additional molecules becomes increasingly harder to remove. Airtech's corporate headquarters and largest manufacturing facility is located in Rutherford, New Jersey. The principle behind positive displacement vacuum pump is create a vacuum by expanding the volume of a container. This type of vacuum pump, expands a cavity and allows the gases to flow out of the sealed environment or chamber. These pumps provide low pressures and have low transfer rates. As you can see, determining what vacuum pump you may need for your gas removal process can vary on so many factors. Liquid ring vacuum pumps, also known as water ring vacuum pumps, contain a single. In research and scientific applications this is extended to 10-9 Torr or lower. The compact and lightweight design of the ORION series dry rotary vane vacuum pump and pressure pump adds to ease of operations. Claw pumps have two rotary claws that counter rotate. For example in a manual water pump, a mechanism expands a small sealed cavity to create a deep vacuum. They also have environmental benefits of not requiring the disposal of oils like lubricated pumps. Our L-Series vacuum pump has integral exhaust filters, vibration isolators, The 3AL is an ideal alternative to a rotary vane vacuum pump and older liquid ring technology. Airtech Vacuum Inc. was established in 1982 and is now a unit of IDEX Corporations Health and Science Technology segment. Let us look at some of the methods used in a vacuum pump. Radial turbopumps have the outlet directed perpendicular to the inlet. Both are considered centrifugal vacuum pumps because curved vanes on the impeller constantly force the fluid outwards, away from the center. This expansion results to creating a partial vacuum and reducing the pressure, which is then filled by air pushed in by atmospheric pressure. It has a self- contained, Airtechs liquid ring vacuum pump and liquid ring compressor are rotating, non-pulsating, positive displacement pumps. As the diaphragm moves up, the volume is decreased, and gas molecules are compressed while flowing to the outlet. In variable pitch models, the gas is compressed at each pitch change and cooled before the next pitch change, resulting in greater efficiency. Scroll pumps use two non-rotating scrolls in a spiral design, where the inner one orbits and traps a gas in the outer volume space. These pumps operate at lower pressure ranges and are categorized under primary or booster pumps and incorporate wet or dry technologies. Rotary vane pumps incorporate a rotor that spins around with attached vanes of either fixed or variable length. A vacuum is an area void of matter. White Tradesman K45 75 125 170 210 400 650, Master Heater MH45 75 135 190 215 400 600KFA, L.B.

These pump types are Rotary Vane, Rotary Lobe, Liquid Ring, Scroll, Dry Screw and Claw pumps with full selection of pressure ranges and pumping speeds to handle the flow rates your vacuum application requires. aspiradora 2227 pngimg pngio Tags: booster pump, capture pumps, claw pump, gas pumps, kinetic pumps, liquid ring pump, Positive Displacement Pumps, primary pump, rotary vane pump, secondary pump, transfer pumps, vacuum pump, Select A StateAlabamaAlaskaArizonaArkansasCaliforniaColoradoConnecticutDelawareFloridaGeorgiaHawaiiIdahoIllinoisIndianaIowaKansasKentuckyLouisianaMaineMarylandMassachusettsMichiganMinnesotaMississippiMissouriMontanaNebraskaNevadaNew HampshireNew JerseyNew MexicoNew YorkNorth CarolinaNorth DakotaOhioOklahomaOregonPennsylvaniaRhode IslandSouth CarolinaSouth DakotaTennesseeTexasUtahVermontVirginiaWashingtonWashington DCWest VirginiaWisconsinWyomingOther, Choose a Primary Product NeedFluid Fill SystemsPumpsCustom SkidsFiltrationMixersGeneral Process EquipmentHeat ExchangersHose & FittingsMechanical Seals, Rough/Low Vacuum: 1000 to 1 mbar / 760 to 0.75 Torr. vacuum process ejector pump liquid ring plant air pumps booster industrial kinney machinery One of the methods used by capture pumps, is by trapping gas molecules through cryogenics to trap gas molecules. Another example of positive displacement vacuum pumps is like a diaphragm muscle expands the chest cavity, causing the volume of lungs to increase.

1) must be able to operate over a portion of an extraordinarily large pressure range, typically varying from 1 to 10-6 Torr / 1.3 to 13.3 mBar of pressure. 2022 Airtech Incorporated. G25 {20kW} Portable Diesel Generator Rental, G40 {30kW} Portable Diesel Generator Rental, G50 {40kW} Portable Diesel Generator Rental, G70 {60kW} Portable Diesel Generator Rental, G85 {78kW} Portable Diesel Generator Rental, G145 {115kW} Portable Diesel Generator Rental, G190 {155kW} Portable Diesel Generator Rental, G240 {190kW} Portable Diesel Generator Rental, G290 {230kW} Portable Diesel Generator Rental, G325 {260kW} Portable Diesel Generator Rental, G450 {365kW} Portable Diesel Generator Rental, G570 {465kW} Portable Diesel Generator Rental, Air-Cooled and Water-Cooled Industrial Chiller Rentals, Tradesman 170 - Propane or Natural Gas Heater Rental, Campo DF650F - Duel Fuel LP/NG Heater Rental, Ameritemp AT500 - Duel Fuel LP/NG Heater Rental, Ameritemp AT1000 - Duel Fuel LP/NG Heater Rental, Ameritemp AT2000 - Duel Fuel LP/NG Heater Rental, Ameritemp AT4000 - Duel Fuel LP/NG Heater Rental, LB White Foreman 230DF or Diesel Indirect Fired Heater Rental, LB White Foreman 500DF or Diesel Indirect Fired Heater Rental, Frost Fighter IDF500 Indirect Fired Heater Rental, MAC 800 Mobile Indirect Fired Heater Rental, Wacker Neuson HI900DGM Mobile Indirect Fired Diesel Air Heater Rental, Heat Wagon 1.0M LP, NG or Diesel Indirect Fired Heater Rental, Generac-MAC Mobile 1.2M Indirect Fired Heater Rental, Generac-MAC Mobile 2.5M Indirect Fired Heater Rental, Wacker Neuson E3000 Ground Heater, W/Generator Rental, Wacker Neuson E1100 Ground Heater, W/Generator Rental, Patron 1.5EH 1.5kW Electric Heater Rental, Fostoria FES-1024-1CA 10EH 10kW Electric Heater Rental, Fostoria FES-1524-3E 15EH 15kW Electric Heater Rental, Fostoria FES-3048-3A 30EH 30kW Electric Heater Rental, Fostoria FES-4548-3 45EH 45kW Electric Heater Rental, Chromalox SDRA-6043RG 60EH 60kW Electric Heater Rental, Chromalox HACS-150 150EH 150kW Electric Heater Rental, Portable Hepa Air Scrubbers & Negative Air Machines Rentals, Power Distribution Spider Boxes & Panels Rentals, 100Amp Panel-6606GUSF-254 Temporary Spider Box Rental, 100A 3 Phase Distr- Cart CamLok Input Rental, 200A 3 Phase Distribution Cart Cam Type Input Rental, 50A California Style Rental Cable Assemblies, 50A California Style Rental Hard-wire Male/Female Tails, 4/0 Single Conductor Cam-Lok Feeder Cable Assembly Rentals, #1, 2 & 4 Banded Cam-Lok Feeder Cable Assembly Rentals, Rental Industrial and Commercial Portable Power Transformers, 15KVA Skid Type Portable Power Rental Transformer, 30KVA Skid Type Portable Power Rental Transformer, 45KVA Skid Type Portable Power Rental Transformer, 75KVA Skid Type Portable Power Rental Transformer, 112.5KVA Skid Type Portable Power Rental Transformer, 150KVA Skid Type Portable Power Rental Transformer, 225KVA Skid Type Portable Power Rental Transformer, 300KVA Skid Type Portable Power Rental Transformer, 375KVA Skid Type Portable Power Rental Transformer, 500KVA Skid Type Portable Power Rental Transformer, 05TCG Auxiliary Fuel Tank Rental 132 Gallon, 10TCG Auxiliary Fuel Tank Rental 264 Gallon, 20TCG Auxiliary Fuel Tank Rental 528 Gallon, 30TCG Auxiliary Fuel Tank Rental 793 Gallon, 40TCG Auxiliary Fuel Tank Rental 1000 Gallon, 50TCG Auxiliary Fuel Tank Rental 1198 Gallon, 100TCG Stationary Fuel Storage Tank Rental 2,232 Gallon, TPI Fostoria Portable Electric Salamander Heat, TPI Fostoria Wall Ceiling Mount Electric Heat, Chromalox DRA Portable Electric Salamander Heat, Berko BDH Portable Electric Salamander Heat, L.B. The other type of positive displacement pump incorporates an oscillating motion. A new generation of dirty water vacuum pumps, based on the principle of the liquid ring system. Whereas, Dry vacuum pumps have no fluid in the pumped gas, relying on precise clearances between the rotating and static parts of the pump, dry polymer (PTFE) seals, or a diaphragm to separate the pumping mechanism from the gas and ensure a tight seal. You can withdraw your consent at any time by unsubscribing in the emails you receive, or by There are rows of equally spaced vanes on each side of the rim. Positive Displacement pumps are grouped by either a rotating or oscillating input motion. Then, the fluid is transferred through the pump and exits from the outlet where the volume stays constant during the whole process. Its common that multiple transfer pumps are used together in parallel to provide higher vacuum and flow rate. Sign up for our newsletter and we'll send you the latest headlines directly to your inbox. contacting us at desmi@desmi.com.

Learn more about vacuum pump applications. Both screws turn in the compressor housing without friction and at very tight clearances. To understand which type of vacuum is most suitable for you and your application, it is crucial to understand the features, benefits and operating principle each type of technology. Due to centrifugal force, these vanes slide out and form chambers between themselves and the housing. Pumps which work by mechanically trapping a volume of gas and moving it through the pump are known as positive displacement pumps. Near the suction or inlet, the volume becomes larger causing the pressure in the each one to drop and draw in gas.

Learn more about vacuum pump applications. Both screws turn in the compressor housing without friction and at very tight clearances. To understand which type of vacuum is most suitable for you and your application, it is crucial to understand the features, benefits and operating principle each type of technology. Due to centrifugal force, these vanes slide out and form chambers between themselves and the housing. Pumps which work by mechanically trapping a volume of gas and moving it through the pump are known as positive displacement pumps. Near the suction or inlet, the volume becomes larger causing the pressure in the each one to drop and draw in gas. These types of pump can achieve high compression ratios at low pressures but typically dont have sealed volumes. Therefore, due to the increase in energy, there is an increase in pressure at the outlet of the pump. vacuum pump liquid ring lx medical busch Airtech Kinetic Blower (AKB) Series are dynamic blowers that transfer kinetic energy to the medium agent by a contactless rotating impeller. A vacuum pump is a device that removes gas molecules or air particles from a sealed volume in order to achieve difference in pressure creating a partial vacuum. Wet pumps lubricate and/or sealing themselves using either oil or water; this fluid can contaminate the pumped (swept) gas. There are no moving parts and there is a reduced pressure at the inlet. Root pumps push gas in one direction through two lobes that mesh without touching as the counter rotate.

4161 Morris Drive, Unit 5

High pressure regenerative blowers manufactured by Airtech make up the 3BA series regenerative vacuum/pressure blowers Our regenerative. The compression ratio is the ratio of the exhaust pressure (outlet) to the lowest pressure obtained (inlet). The range of centrifugal pumps is made to meet the requirements of a wide array of different applications. All Rights Reserved. The gas is taken in through the inlet. There are two basic categories of vacuum pump: Gas Transfer Pumps and entrapment or capture pumps (Figure 1). Centrifugal pumps work by converting rotational kinetic energy into hydrodynamic energy. Centrifugal force in the impeller blades accelerates the gas outward and the pressure increases. By using extremely cold temperatures, they effectively draw molecules inward to create a vacuum. slurry pump errosion resistant technologies flow metallic Also, they are common in buildings where gas and water lines need to be pumped throughout the building. This is kept separate from the vacuum compression side. Therefore, an industrial vacuum system (Fig. Liquid Ring pumps are useful for both vacuum and compression situations. Vacuum is a space devoid of matter where the gaseous pressure inside this volume is below atmospheric pressure. Airtech is a leading manufacturer of regenerative blowers. The fluid in a regenerative pump flows through the vanes multiple different times, unlike a standard centrifugal pump. As it enters the side channel, the rotating impeller imparts velocity to the gas in the direction of rotation. Liquid Ring Pump (Wet, Primary): Pressure of 30 mbar, Pumping Speed 25 30,000 m3/h (15 17,700 ft3/min). Home Industry Knowledge & Insights How do Vacuum Pumps Work? The Claws come within 2/1000 of each other, but never actually touch. Roots-type utilize lobes that mesh together and are commonly used to supercharge Otto engines. Vacuum is a utility used in a vast array of industrial manufacturing processes including packaging, bottling, drying, degassing, pick and place to name but a few. The suction forces the fluid to enter the pump. Centrifugal pumps can have different structures, but their operating principle and fluid dynamic characteristics are always the same. For this reason, rotary pumps are utilized for both high and low-pressure needs. Pressure will always try to equalize across connected regions as gas molecules flow from high to low to fill the entire area of that volume. Cooling is achieved using a water cooled outer chamber. Because of the pressure, some fluid from the chamber is pushed into the pumps small cavity. This article will review the most common types of industrial vacuum pump, how they work and in what types of applications they are best suited. Applications include using a vacuum to preserve food or transferring gas from a gas tank to the engine. Often designed in multiple stages on a single drive shaft, the isolated volume is compressed to a smaller volume at a higher pressure, and finally the compressed gas is expelled to either atmosphere or the next pump. Depending on the specific conditions the pump is exposed to, such as room pressure and temperature, different vacuum pressures The company you choose should help with the pumps concept and design, and offer excellent after-sale service and support, although you may not need it. They are synchronized via a precision gear. When the diaphragm is in the low position, volume in the chamber increases, lowering the pressure and pulling air molecules in.