Every meter technology will have its advantages and disadvantages, but its the nuances of your system and what is flowing through it that should garner the most attention. Specifically, the time it takes for an ultrasonic signal to travel against the flow (i.e., upstream), tup, is longer than it takes following the flow (i.e., downstream), tdn. doppler disadvantages NEWSLETTER SIGNUP Our quarterly newsletter is a resource for those in the oil, gas and related industries. If you are interested in more details of turndown ratio, please visit Wikipediato learn more. How to use smart instrument measurement for better monitoring and control. As a key player, we have been working hard to lower price of ultrasonic flowmeters. principle working Ultrasonic flow meters will detect and measure flow rates without invading the flow stream or using moving parts. Both of them can measure flow by transmitting and receiving ultrasound wave in pipe.

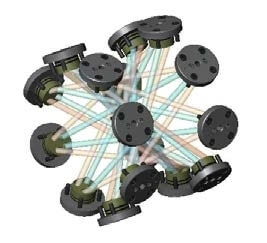

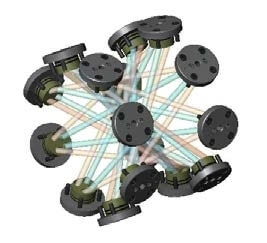

The Elster-Instromet Q.Sonic-plus ultrasonic meter works well for custody transfer of natural gas, as well as other applications in gas exploration, transmission, and distribution. Magnetic flow meters are specifically designed for systems that move conductive fluids like water, acids, caustic liquids, and slurries. As end users are increasingly looking to technology to optimize operations and reduce cost, ultrasonic solutions have risen in popularity due to these benefits. Steam flow measurements will continue to be critical in chemical and petrochemical industries as users continue to minimize energy costs and optimize process performance. A single ultrasonic flow meter can cover a wide range of flows, providing users with additional savings. # Ultrasonic flowmeters are more expensive than the Doppler version. Doppler open channel measurement can use one transducer to measure velocity, level and fluid conductivity. Heating could take the form of warming a house or building to being a part of a large district heating system in which steam consumption is a significant concern due to billing and energy rebates. The flow meter will not suffer normal wear and tear. flowmasonic flowmeter wuf pdam utilizes lanjut Meanwhile, the flow accuracy will degrade as using of moving parts.As its using, the moving parts will become bad and users have to replace a new flow measurement device. Copyright Cahaba Media Group, Inc. All Rights Reserved. Transit time flow meter uses a pair of transducers both are capable of sending and sensing the sound signals. You also have the option to opt-out of these cookies. Ultrasonic measurements are made by attaching two transducers onto the outside of a pipe. # Requires upstream, downstream straight pipeline, 15 pipe diameters. Equation 1 shows that the operation of an ultrasonic flow meter strongly depends on the timing of tup, tdn, and the dimensional measurement of path length P and angle 0. There are multiple industrial applications that call for the accurate flow measurement. The ultrasonic gas flow meter is a velocity-type flow meter, a classification of meters that includes turbine meters and vortex meters. b. The incident wave is received at the other end with a time span. There are two major types of ultrasonic flowmeters: Doppler and transit time type. Ultrasonic meters have high initial costs. Our ultrasonic flow meters provide advanced and precision energy measurement and widely used for water energy monitor in HVAC management. Additionally, it will determine the direction of the flow with the aid of an ultrasonic beam.

As end users are increasingly looking to technology to optimize operations and reduce cost, ultrasonic solutions have risen in popularity due to these benefits. Steam flow measurements will continue to be critical in chemical and petrochemical industries as users continue to minimize energy costs and optimize process performance. A single ultrasonic flow meter can cover a wide range of flows, providing users with additional savings. # Ultrasonic flowmeters are more expensive than the Doppler version. Doppler open channel measurement can use one transducer to measure velocity, level and fluid conductivity. Heating could take the form of warming a house or building to being a part of a large district heating system in which steam consumption is a significant concern due to billing and energy rebates. The flow meter will not suffer normal wear and tear. flowmasonic flowmeter wuf pdam utilizes lanjut Meanwhile, the flow accuracy will degrade as using of moving parts.As its using, the moving parts will become bad and users have to replace a new flow measurement device. Copyright Cahaba Media Group, Inc. All Rights Reserved. Transit time flow meter uses a pair of transducers both are capable of sending and sensing the sound signals. You also have the option to opt-out of these cookies. Ultrasonic measurements are made by attaching two transducers onto the outside of a pipe. # Requires upstream, downstream straight pipeline, 15 pipe diameters. Equation 1 shows that the operation of an ultrasonic flow meter strongly depends on the timing of tup, tdn, and the dimensional measurement of path length P and angle 0. There are multiple industrial applications that call for the accurate flow measurement. The ultrasonic gas flow meter is a velocity-type flow meter, a classification of meters that includes turbine meters and vortex meters. b. The incident wave is received at the other end with a time span. There are two major types of ultrasonic flowmeters: Doppler and transit time type. Ultrasonic meters have high initial costs. Our ultrasonic flow meters provide advanced and precision energy measurement and widely used for water energy monitor in HVAC management. Additionally, it will determine the direction of the flow with the aid of an ultrasonic beam.

It is mandatory to procure user consent prior to running these cookies on your website. 6 Styles of Natural Gas Meters (Including Residential), Diaphragm Meter by Itron, Honeywell Elster Turbine Flowmeter, Measurement and Control of Natural Gas, Rotary Gas Meter, Slam Shut Valves, Regulators, and OPSO Regulator. The transducers send and receive ultrasonic pulses through the steam. High accuracy and stable performance can help to reduce your energy cost. The signal sends in both directions upstream and downstream. We use cookies for various purposes including analytics and personalized marketing. # Flow measurements in large pipes can be done. If you are in the market for an ultrasonic flow meter, submit your inquiry here. Now the ultrasonic signals have different transit times. K = constant of proportionality In steam cracking, steam is introduced with a feedstock and sent to a cracking furnace to break the feedstock molecules into more valuable components. Tom Michalowski is senior product manager for Panametrics, a Baker Hughes business. Ultrasonic flow meters can provide a very low flow measurement for process control. Water must contain a certain amount of Microsiemens (uS), giving it the power to conduct heat and/or electricity. But ultrasonic flow meters can support 3 types of flow sensors.Complete facilities can ensureenough your reselling business and make you gain more orders. In the chemical and petrochemical industry, steam is commonly used for heat exchanging and as a reactant for steam cracking. c = speed of wave in process fluid. This installation method is perfect for all situations in which neither cutting the pipes nor the shutting down of the process arent possible. Variety of scan rates, noise cancellation, Digital Signal Processing (DSP), etc. Historically the market is moving away from Doppler to transit time technologies because transit-time techniques are continuing to improve while Doppler technologies remain stagnant. This field is for validation purposes and should be left unchanged. The conductive media/liquid then creates a voltage as it passes through the flow tube and magnetic field of the meter. Ultrasonic flow meters are the equipment of choice whenever the contact with the measured fluid isnt possible. It avoids pollution to the fluid. Learn the ins and outs of how AODD pumps work in this webinar. The greater the velocity the higher the voltage, thus creating the proportional signal that is eventually converted to volumetric flow. For cleaning, steam is consumed for sterilization or deep cleaning in the pharmaceutical, food and beverage and other industries. Users just need to clamp the flow sensor to pipe surface. Transit-time flow meters are not suited for water with heavy aeration or high concentrations of solids or suspended particles as this can obstruct the sound waves. Digital signal processing has made it possible to use a transmitted signal via the use of digital signal coding. Part 2, Here is Why Energy Sector Industries Benefit from our HEATX-2 BTU Meters, Advantages and Disadvantages of Inline vs. Insertion Volumetric Flow Meters, Three Tips for Selecting a Hot/Chilled Water BTU System to Improve Accuracy, Three Tips for maximizing your Volumetric Flow Meters Efficiency, How to Simplify the Measurement of a Buildings Energy Consumption, A Guide to Different Types of Energy Meters [Infographic], Metering A Heating System: Condensate Vs.

Remote alarm notification software was a crucial component to the operation. ultrasonic flowmeters This features plays an important role in ultrasonic water meter and ultrasonic heat meter. The staff is responsive, collaborative, communicative, and places great effort in prioritizing our needs. However, advances in transit time technologies mitigates some of these fluid conditions. gives user many choices. Here we discuss the pros and cons of ultrasonic flowmeters. They are less accurate (about 1%) than the inline meter and used for monitoring, check metering, temporary flow measurement, and leak detection. flowmeter ultrasonic technique? Magnetic flow meters (a.k.a magmeters) measure flow rates by employing Faradays Law of Electromagnetic Induction. This type of flowmeter requires objects in the flow stream. a. Cant measure cement/concrete pipe or pipe with such material lining. The Benefits of Using Ultrasonic Flow Meters for Steam Measurement, Using Digital Solutions to Cut Costs & Increase Uptime, The Advantages of Popular Fieldbus Networks, IoT Creates More Reliable Irrigation System for Oregon Farm, Deragging Aids Wastewater Spillage Prevention, How IIoT Early Anomaly Detection Increases Reliability & Productivity, Software Helps Water Utility Avoid Unplanned Downtime, Basics of AODD Pumps & the Technical Advantages, Vacuum Technology Fundamentals & Innovations, Increasing the Lifespan & Reliability of Electronic Components, In-depth articles on pump industry issues, Expert insights into important topics in the field. The electrodes sense and measure the voltage created as the liquid passes through the tube. These cookies will be stored in your browser only with your consent. This is very different from traditional flow devices. f = incident frequency Any shift in the frequency of reflections is proportional to the flow velocity. The incident wave hit the object or bubbles and reflects back as the reflected wave, the difference in the frequencies of the incident and reflected waves are measured which is proportional to the function of fluid flow in the stream. When it comes to measuring steam, ultrasonic technology may provide advantages over traditional technologies. In addition, it is shown that flow velocity measurement is independent of the medium flowing inside the pipe. Finally, the AlsonicDSP ultrasonic product line flow meters can be used to measure fluids that contain up to 30 percent gas bubbles or solids. Conversely, the piezoelectric crystal creates a voltage when the ultrasonic signals touch the sensor. Lets talk about water applications, for example. Unfortunately, measuring steam flow is not easy. These sound waves are generated by a pair of transducers. Most ultrasonic manufactures use low frequency sound pulses to measure the transit time there by severely limits their accuracy when bubbles/particles reach between 1-2% concentrations. However, to alleviate some of its inaccuracies, transit-time ultrasonic meters can also use in multiple path configurations to achieve higher accuracies. Ultrasound technology provides possibility to develop low power consumption ultrasonic flow meters. The measured difference in the wavelengths (transmitted verses reflected) is proportional to the process velocity. 2.No Direct Contact to Fluid Accuracy may be affected by air space in the pipe, Accuracy may be affected by the size distribution of particles and any relative velocity between particles and the water (Doppler). With these process steam flow measurements, it is critical to optimize performance and not waste energy or money from the generation of steam. t down = Time for sound pulse to travel from upstream location to downstream location, No moving parts and allow unabstracted flow, Unaffected by temperature, density and concentration. document.getElementById( "ak_js_2" ).setAttribute( "value", ( new Date() ).getTime() ); Click to share on Twitter (Opens in new window), Click to share on Facebook (Opens in new window), Click to share on LinkedIn (Opens in new window), Click to share on Tumblr (Opens in new window), Click to share on WhatsApp (Opens in new window), Absolute, Gauge, Atmospheric, and Vacuum Pressures. This article focuses on inline ultrasonic meters, not clamp-on. 1.No Pipe Cutting 10.Versatile Outputs and Data Storing Traditionally flow meters that use the transit time method were used only in conditions of clean fluids, with barely any gas bubbles or suspended solids. Micronics Ltd, Knaves Beech Business Centre, Davies Way, Loudwater, High Wycombe, Bucks, HP10 9QR, United Kingdom. We also use third-party cookies that help us analyze and understand how you use this website. Types of Cable trays, and it's selection. With the clamp-on design, the flow rate can be measured in a very large pipe line up to 4 meters in diameter. clamp calibrator calibration flowmeter Doppler technologies are only used where Transit-times techniques fails which is where there is a very high concentration of particles/bubbles.Both Doppler and Transit-time techniques have transducers that can either be inserted into a pipe or on the outside of a pipe. They can be retrofitted at any time without interrupting the process. This increases the accuracy of the flow rate measurement. This will destroy the flow status. 14.HVAC Energy Management, Reduce Your Cost Meanwhile, even though it requires maintenance, the flow wont be stopped and production can continue. ultrasonic clamp gas flow control midstream flexim process meter meters shale extraction processing transport instrumentation valve industrial sold Any number of unknown internal piping variables can shift the flow signal and create inaccuracies.

document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); document.getElementById( "ak_js_2" ).setAttribute( "value", ( new Date() ).getTime() ); Address: The relationship between flow speed and transit time: Q = Calculated volumetric flow 13. document.getElementById( "ak_js_3" ).setAttribute( "value", ( new Date() ).getTime() ); The AlsonicDSP product line are used in both fixed and portable application as well as more complicated Area Velocity open channel techniques for sewers, small channels and rivers.

This article is a continuing series on types of gas flow meters. They are non-invasive, and therefore can detect in-situ flow rates from outside the pipework, with no interruption to flow or the process. But if possible, it is better to select digital flow meter without moving parts, e.g. If pipe is seriously rusted, especially inner wall rusting, clamp on meter may not work well. document.getElementById( "ak_js_2" ).setAttribute( "value", ( new Date() ).getTime() ); We are the master distributor of GPL Odorizers, eco-friendly odorant injection systems. These calculations take into consideration some user-entered data, as well. The relation between fluid flow and frequency shit: ^f = frequency shift Is it ionized? The transducers are mounted, one opposite to another with an elevation which forms an upstream and downstream. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); Susan Bender started selling to the natural gas industry in 1980. For example, ultrasonic flow meters are known to have a high turndown ratio, which means users can measure steam during seasons when consumption is typically low. Meanwhile, we also develop big memory storing data logger for our ultrasonic flow meters and related data management software is available. The diagram below describes the theory of operation for Doppler techniques. Ultrasonic flowmeters pass high-frequency sound wave to fluid path to measure the fluid velocity. ), If you are looking for regulators, the following is also helpful: gas type, inlet, and outlet pressure (PSI or WC), flow range (BTU/H or CFH), desired pipe size, application, regulator location (inside or outside? The meter measures the difference between the upstream and downstream transit times and uses digital signal processing to calculate velocity and volumetric flow rate. 3.No Risk of Leakage Also known as counter propagation flowmeter. But opting out of some of these cookies may have an effect on your browsing experience. ultrasonic meter water disadvantages advantages viz meters flow types main there These piezo-type transducers can be mounted either on the exterior or inside the pipes. flowmeter ultrasonic advantages disadvantages benefits If the reflected wave returns from a bubble advancing toward the ultrasonic transducer, the reflected frequency will be greater than the incident frequency. ultrasonic flowmeter wuf ip The difference between upstream and downstream traveling times, t, is directly proportional to the flow velocity as seen in Equation 1. Not All Flow Meters Are Created Equal! What is 1oo1, 1oo2, 2oo2, and 2oo3 voting? principle limitations ultrasonic benefits After tens of years, we are proud to announce that we have done it. Learn how performance and deviation from control limits can be visualized to allow operators and engineers to understand parameters affecting reliability. Read more about the different types ofUltrasonic Flow meters: Clamp On Ultrasonic Flow MetersOpen Channel Flow MeterPortable Ultrasonic Flow MetersUltrasonic BTU Meters. Low flow measurement has been a hard problem since flow measurement available. In 1990 she founded Linc Energy Systems, where she remains as President and CEO. ultrasonic flowmeter flowmeters electromagnetic The main advantage provided is ultrasonic measurements are non-invasive. Doppler ultrasonic flowmeters are based on the Doppler-shift or the phenomenon in which the wavelength of an approaching sound source is shorter than the wavelength of that same source as it is moving away. Most transit time ultrasonic flow meters require that the process either be clean, meaning there are few solids or gas bubbles in a liquid, or has no trapped liquid in a gas, and the piping must be closed. The time needed to arrive is measured in both situations. Any cookies that may not be particularly necessary for the website to function and is used specifically to collect user personal data via analytics, ads, other embedded contents are termed as non-necessary cookies. waste-water). Widely used in majority ultrasonic applications. The difference between the two intervals of time is a function of flow direction and velocity, and it represents an accurate measure for the average velocity of the liquid flowing through a pipe. This is the parameter being used by ultrasonic flowmeters to calculate the liquid flow rate. flowmeter ultrasonic instrument industrial clamp sil valve process solutions control meters fluxus series Its long-term accuracy is proven to be better than traditional mechanical flow meters. But because of special, its price is always very high and is not easy to promote for common application. By continuing to use the service, you agree to our use of cookies. For small size pipe, people can develop special flow devices to test. Usually used transducers are piezoelectric transducers. 7.Low Flow Startup In the case of steam, steam density, , can be readily computed using a steam table if temperature, pressure and steam quality are known. Advanced technologies of digital signal processing have made it possible to attach digital coding to the beamed sound waves. Is noise an issue? The scaling, pitting, and fouling that can occur over time in older piping systems can be problematic. Almost zero pressure drop (Since the coefficient of friction for the liner materials (Teflon) may be lower than the actual piping material they may provide less of a pressure drop than the same length of piping material), Flow range turn-down of 300 to 1 or better, Available for pipe diameters from 1/10 to 120, Relatively unaffected by viscosity, temperature and pressure as long as the magmeter is selected based on the process conditions, Applicable to all flow profiles and does not require straight run (only the CMAG can make this statement. The main one is it has a higher requirement of pipe condition. Transit time required clean liquid and doppler meter need objects in the liquid. As there is no moving parts and no pipe cutting, clamp on ultrasonic flow meters wont almost require bigger maintenance. The combination of clamp on flow and RTD products a clamp on energy measurement and doesnt need to damage pipe. Since particles or bubbles in a stream flow at different speeds, it is impossible for this technology to measure all the particles/bubble velocities to calculate the true average flow in a flow stream.

This website uses cookies to improve your experience. Using ultrasonic transducers, these flow meters can measure average velocity of along a beam of ultrasound, and then taking averages of the transit time (by measuring differences in pulses of ultrasound propagating into & against flow direction), or alternatively recording frequency shift using the Doppler effect. What are the Advantages of an Ultrasonic Flow Meter? Contactthe experts at SmartMeasurement today! This field is for validation purposes and should be left unchanged. They vary greatly in purchase price but can often be very inexpensive to use and certainly to maintain, again due to the fact they do not use moving parts, unlike mechanical flow meters. The signal continues through the fluid is reflected on the opposite pipe wall then measured by the 2nd sensor. Compact ultrasonic transducers are either installed in a flow cell (spool piece) or directly in the steam pipe, one upstream of the other with mounting nozzles. 4.No Moving parts Inside the Ultrasonic Flowmeter, pairs of sensors are fitted across the tube in opposite to each other. We are an authorized distributor for Honeywell Elster Instromet ultrasonics: Q.Sonic, Q.Sonic-Plus, and TwinSonic-Plus. An ultrasonic flow meter is a type of flow meter that can measure velocity of fluids with ultrasound technology (the sound generated above the human hearing range) to work out the volume flow. Your system would not need to be shut down and your piping would not need to be altered. Nearly allof flow meters only have 1 or 2 type flow sensors optional: inline flow meter or insertion flow meters. She attributes her success to her philosophy, The customer is king (or queen), which remains part of her companys mission. Please give us as much detail as possible so we can provide the best response (product, model, p/n, manufacturer, size, quantity, etc. Energy Meters, Energy Management, Building Services & Group or District Heating Schemes. They are nonintrusive as the transmitters clamp to the outside of the pipe. This difference in time is proportional to the velocity of the flow. In most situations, the exterior installation works very well. This advantage is more suitable for strong acid, alkali, poisoning, corrosive liquid, etc. 4 Things to Consider Before Selecting a Gas Flow Meter Technology, Gas Flow Meter Types Mass Flowmeter, Volumetric Flow, and , Direct Mass Flow Meter: Coriolis versus Thermal Mass Flow Meters, 4 Steps to Select the Correct Natural Gas Flow Meter, GasLab Q2 Natural Gas Analyzer for Feedforward Combustion Control, Ultrasonic flow meters can measure the flow of. ultrasonic flowmeter. Best Flow Technologies for Each Fluid State, Estimated Cost of Various Flow Technologies, Flow Technologies & Process Limits - Metric, Obstruction less flow clamp on outside the pipe, Pressure drops equal to an equivalent length of straight pipe, Accuracy about 1% of flow rate standard and 0.5% with dual path. doppler ultrasonic doppler ), Can respond well to rapid changes in flow, Applicable to liquids with heavy particulates, Available in a wide variety of communication protocols, Ability to register locally, remotely or to interface with an energy management system. Transit-Time Ultrasonic Flow Meters send a sound wave through the flow, relying on the difference in time between upstream and downstream times of flight. Steam users also desire a relatively high turndown or flow measurement range to understand energy usage during peak and low demand needs. 8.No Future Maintenance Why a 4-20 mA signal is used, not 0-20 mA or 0- 30 mA signal in Instrumentation ? For water in many forms, magnetic and ultrasonic flow meters have become popular technologies. Doppler technologies are only used where the fluid which has a high concentration of solids and bubbles in the flow stream and often times cannot measure fluid flow accurately, due to its unique technique in using particle or bubble velocities in the flow stream to measure the overall flow rate of the fluid.

But plus installing fee, life span and maintenance, its total cost is not higher, even lower. 11.Low Power Consumption Visualizing vibration through motion amplification allows users to diagnose critical equipment and improve asset reliability. # For the measurement of low flow rates, the ultrasonic flowmeter is a better option compared to the Vortex flowmeter. Steam has the challenge of operating at high temperatures and across a wide pressure range, from close to ambient pressures to significant high pressures, based on final use cases and requiring little pressure drop to not waste energy. The ideal tool for potable water applications, clamp-on ultrasonic flow meters can also be used in wastewater treatment and collection applications. By far, the best reason to use an ultrasonic flow meter of any kind is the lower costs associated with installation. You may have an interest in related posts: Currently, over 90% of ultrasonic fluid measurement uses transit-time ultrasonic technologies of various scan frequencies, unique algorithms, noise cancellation techniques. These flow meters require little maintenance, as the sensors will not contact with the flow, as they have no moving parts, it means no obstruction and no general wear and tear. No pressure drops are experienced with clamp-on flow meters. Traditional mechanical flow meters must use moving parts to sense flow. But, does the water contain bubbles or particles? You may unsubscribe at any time. The ultrasonic signals are generated by piezoelectric crystals applying a voltage. If the flow reverses direction and the reflected wave returns from a bubble travelling away from the transducer, the reflected frequency will be less than the incident frequency. Clamp on flow sensors dont need to contact fluid directly. Magnetic Flow Meter Working principle, Advantages, and Limitations. Low Cost Ownership t up = Time for sound pulse to travel from downstream location to upstream location The transducer emits a sonic beam into the process and entrained particles or bubbles reflect the beam back to the transducer. Clamp on installing way doesnt need to cut pipe. Benefits of Transit time Ultrasonic technologies, Benefits of Doppler Ultrasonic technologies. Your email address will not be published. 15 Advantages of Ultrasonic Flowmeter Make it Unique.

What is NDT testing (Non-Destructive testing)? Excellent for sewers and small channels for Area Velocity open channel measurement.

The mass flow is then calculated from temperature and pressure inputs and built-in steam tables.

Transit-time ultrasonic flow meters are usually considerably more accurate than Doppler measurement. With clamp-on sensors, the ultrasonic signals are passed directly on to the pipe wall into the fluid. They are perfect for applications where flow disruption is simply not an option. Traditional flow meter has a small turndown ratio, e.g. The first investigation may be higher than mechanical flow meters. While selecting the proper flow meter technology for your system is critical, your ability to rely on the meters readings will depend more heavily on the application.

The Elster-Instromet Q.Sonic-plus ultrasonic meter works well for custody transfer of natural gas, as well as other applications in gas exploration, transmission, and distribution. Magnetic flow meters are specifically designed for systems that move conductive fluids like water, acids, caustic liquids, and slurries.

As end users are increasingly looking to technology to optimize operations and reduce cost, ultrasonic solutions have risen in popularity due to these benefits. Steam flow measurements will continue to be critical in chemical and petrochemical industries as users continue to minimize energy costs and optimize process performance. A single ultrasonic flow meter can cover a wide range of flows, providing users with additional savings. # Ultrasonic flowmeters are more expensive than the Doppler version. Doppler open channel measurement can use one transducer to measure velocity, level and fluid conductivity. Heating could take the form of warming a house or building to being a part of a large district heating system in which steam consumption is a significant concern due to billing and energy rebates. The flow meter will not suffer normal wear and tear. flowmasonic flowmeter wuf pdam utilizes lanjut Meanwhile, the flow accuracy will degrade as using of moving parts.As its using, the moving parts will become bad and users have to replace a new flow measurement device. Copyright Cahaba Media Group, Inc. All Rights Reserved. Transit time flow meter uses a pair of transducers both are capable of sending and sensing the sound signals. You also have the option to opt-out of these cookies. Ultrasonic measurements are made by attaching two transducers onto the outside of a pipe. # Requires upstream, downstream straight pipeline, 15 pipe diameters. Equation 1 shows that the operation of an ultrasonic flow meter strongly depends on the timing of tup, tdn, and the dimensional measurement of path length P and angle 0. There are multiple industrial applications that call for the accurate flow measurement. The ultrasonic gas flow meter is a velocity-type flow meter, a classification of meters that includes turbine meters and vortex meters. b. The incident wave is received at the other end with a time span. There are two major types of ultrasonic flowmeters: Doppler and transit time type. Ultrasonic meters have high initial costs. Our ultrasonic flow meters provide advanced and precision energy measurement and widely used for water energy monitor in HVAC management. Additionally, it will determine the direction of the flow with the aid of an ultrasonic beam.

As end users are increasingly looking to technology to optimize operations and reduce cost, ultrasonic solutions have risen in popularity due to these benefits. Steam flow measurements will continue to be critical in chemical and petrochemical industries as users continue to minimize energy costs and optimize process performance. A single ultrasonic flow meter can cover a wide range of flows, providing users with additional savings. # Ultrasonic flowmeters are more expensive than the Doppler version. Doppler open channel measurement can use one transducer to measure velocity, level and fluid conductivity. Heating could take the form of warming a house or building to being a part of a large district heating system in which steam consumption is a significant concern due to billing and energy rebates. The flow meter will not suffer normal wear and tear. flowmasonic flowmeter wuf pdam utilizes lanjut Meanwhile, the flow accuracy will degrade as using of moving parts.As its using, the moving parts will become bad and users have to replace a new flow measurement device. Copyright Cahaba Media Group, Inc. All Rights Reserved. Transit time flow meter uses a pair of transducers both are capable of sending and sensing the sound signals. You also have the option to opt-out of these cookies. Ultrasonic measurements are made by attaching two transducers onto the outside of a pipe. # Requires upstream, downstream straight pipeline, 15 pipe diameters. Equation 1 shows that the operation of an ultrasonic flow meter strongly depends on the timing of tup, tdn, and the dimensional measurement of path length P and angle 0. There are multiple industrial applications that call for the accurate flow measurement. The ultrasonic gas flow meter is a velocity-type flow meter, a classification of meters that includes turbine meters and vortex meters. b. The incident wave is received at the other end with a time span. There are two major types of ultrasonic flowmeters: Doppler and transit time type. Ultrasonic meters have high initial costs. Our ultrasonic flow meters provide advanced and precision energy measurement and widely used for water energy monitor in HVAC management. Additionally, it will determine the direction of the flow with the aid of an ultrasonic beam. It is mandatory to procure user consent prior to running these cookies on your website. 6 Styles of Natural Gas Meters (Including Residential), Diaphragm Meter by Itron, Honeywell Elster Turbine Flowmeter, Measurement and Control of Natural Gas, Rotary Gas Meter, Slam Shut Valves, Regulators, and OPSO Regulator. The transducers send and receive ultrasonic pulses through the steam. High accuracy and stable performance can help to reduce your energy cost. The signal sends in both directions upstream and downstream. We use cookies for various purposes including analytics and personalized marketing. # Flow measurements in large pipes can be done. If you are in the market for an ultrasonic flow meter, submit your inquiry here. Now the ultrasonic signals have different transit times. K = constant of proportionality In steam cracking, steam is introduced with a feedstock and sent to a cracking furnace to break the feedstock molecules into more valuable components. Tom Michalowski is senior product manager for Panametrics, a Baker Hughes business. Ultrasonic flow meters can provide a very low flow measurement for process control. Water must contain a certain amount of Microsiemens (uS), giving it the power to conduct heat and/or electricity. But ultrasonic flow meters can support 3 types of flow sensors.Complete facilities can ensureenough your reselling business and make you gain more orders. In the chemical and petrochemical industry, steam is commonly used for heat exchanging and as a reactant for steam cracking. c = speed of wave in process fluid. This installation method is perfect for all situations in which neither cutting the pipes nor the shutting down of the process arent possible. Variety of scan rates, noise cancellation, Digital Signal Processing (DSP), etc. Historically the market is moving away from Doppler to transit time technologies because transit-time techniques are continuing to improve while Doppler technologies remain stagnant. This field is for validation purposes and should be left unchanged. The conductive media/liquid then creates a voltage as it passes through the flow tube and magnetic field of the meter. Ultrasonic flow meters are the equipment of choice whenever the contact with the measured fluid isnt possible. It avoids pollution to the fluid. Learn the ins and outs of how AODD pumps work in this webinar. The greater the velocity the higher the voltage, thus creating the proportional signal that is eventually converted to volumetric flow. For cleaning, steam is consumed for sterilization or deep cleaning in the pharmaceutical, food and beverage and other industries. Users just need to clamp the flow sensor to pipe surface. Transit-time flow meters are not suited for water with heavy aeration or high concentrations of solids or suspended particles as this can obstruct the sound waves. Digital signal processing has made it possible to use a transmitted signal via the use of digital signal coding. Part 2, Here is Why Energy Sector Industries Benefit from our HEATX-2 BTU Meters, Advantages and Disadvantages of Inline vs. Insertion Volumetric Flow Meters, Three Tips for Selecting a Hot/Chilled Water BTU System to Improve Accuracy, Three Tips for maximizing your Volumetric Flow Meters Efficiency, How to Simplify the Measurement of a Buildings Energy Consumption, A Guide to Different Types of Energy Meters [Infographic], Metering A Heating System: Condensate Vs.

Remote alarm notification software was a crucial component to the operation. ultrasonic flowmeters This features plays an important role in ultrasonic water meter and ultrasonic heat meter. The staff is responsive, collaborative, communicative, and places great effort in prioritizing our needs. However, advances in transit time technologies mitigates some of these fluid conditions. gives user many choices. Here we discuss the pros and cons of ultrasonic flowmeters. They are less accurate (about 1%) than the inline meter and used for monitoring, check metering, temporary flow measurement, and leak detection. flowmeter ultrasonic technique? Magnetic flow meters (a.k.a magmeters) measure flow rates by employing Faradays Law of Electromagnetic Induction. This type of flowmeter requires objects in the flow stream. a. Cant measure cement/concrete pipe or pipe with such material lining. The Benefits of Using Ultrasonic Flow Meters for Steam Measurement, Using Digital Solutions to Cut Costs & Increase Uptime, The Advantages of Popular Fieldbus Networks, IoT Creates More Reliable Irrigation System for Oregon Farm, Deragging Aids Wastewater Spillage Prevention, How IIoT Early Anomaly Detection Increases Reliability & Productivity, Software Helps Water Utility Avoid Unplanned Downtime, Basics of AODD Pumps & the Technical Advantages, Vacuum Technology Fundamentals & Innovations, Increasing the Lifespan & Reliability of Electronic Components, In-depth articles on pump industry issues, Expert insights into important topics in the field. The electrodes sense and measure the voltage created as the liquid passes through the tube. These cookies will be stored in your browser only with your consent. This is very different from traditional flow devices. f = incident frequency Any shift in the frequency of reflections is proportional to the flow velocity. The incident wave hit the object or bubbles and reflects back as the reflected wave, the difference in the frequencies of the incident and reflected waves are measured which is proportional to the function of fluid flow in the stream. When it comes to measuring steam, ultrasonic technology may provide advantages over traditional technologies. In addition, it is shown that flow velocity measurement is independent of the medium flowing inside the pipe. Finally, the AlsonicDSP ultrasonic product line flow meters can be used to measure fluids that contain up to 30 percent gas bubbles or solids. Conversely, the piezoelectric crystal creates a voltage when the ultrasonic signals touch the sensor. Lets talk about water applications, for example. Unfortunately, measuring steam flow is not easy. These sound waves are generated by a pair of transducers. Most ultrasonic manufactures use low frequency sound pulses to measure the transit time there by severely limits their accuracy when bubbles/particles reach between 1-2% concentrations. However, to alleviate some of its inaccuracies, transit-time ultrasonic meters can also use in multiple path configurations to achieve higher accuracies. Ultrasound technology provides possibility to develop low power consumption ultrasonic flow meters. The measured difference in the wavelengths (transmitted verses reflected) is proportional to the process velocity. 2.No Direct Contact to Fluid Accuracy may be affected by air space in the pipe, Accuracy may be affected by the size distribution of particles and any relative velocity between particles and the water (Doppler). With these process steam flow measurements, it is critical to optimize performance and not waste energy or money from the generation of steam. t down = Time for sound pulse to travel from upstream location to downstream location, No moving parts and allow unabstracted flow, Unaffected by temperature, density and concentration. document.getElementById( "ak_js_2" ).setAttribute( "value", ( new Date() ).getTime() ); Click to share on Twitter (Opens in new window), Click to share on Facebook (Opens in new window), Click to share on LinkedIn (Opens in new window), Click to share on Tumblr (Opens in new window), Click to share on WhatsApp (Opens in new window), Absolute, Gauge, Atmospheric, and Vacuum Pressures. This article focuses on inline ultrasonic meters, not clamp-on. 1.No Pipe Cutting 10.Versatile Outputs and Data Storing Traditionally flow meters that use the transit time method were used only in conditions of clean fluids, with barely any gas bubbles or suspended solids. Micronics Ltd, Knaves Beech Business Centre, Davies Way, Loudwater, High Wycombe, Bucks, HP10 9QR, United Kingdom. We also use third-party cookies that help us analyze and understand how you use this website. Types of Cable trays, and it's selection. With the clamp-on design, the flow rate can be measured in a very large pipe line up to 4 meters in diameter. clamp calibrator calibration flowmeter Doppler technologies are only used where Transit-times techniques fails which is where there is a very high concentration of particles/bubbles.Both Doppler and Transit-time techniques have transducers that can either be inserted into a pipe or on the outside of a pipe. They can be retrofitted at any time without interrupting the process. This increases the accuracy of the flow rate measurement. This will destroy the flow status. 14.HVAC Energy Management, Reduce Your Cost Meanwhile, even though it requires maintenance, the flow wont be stopped and production can continue. ultrasonic clamp gas flow control midstream flexim process meter meters shale extraction processing transport instrumentation valve industrial sold Any number of unknown internal piping variables can shift the flow signal and create inaccuracies.

document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); document.getElementById( "ak_js_2" ).setAttribute( "value", ( new Date() ).getTime() ); Address: The relationship between flow speed and transit time: Q = Calculated volumetric flow 13. document.getElementById( "ak_js_3" ).setAttribute( "value", ( new Date() ).getTime() ); The AlsonicDSP product line are used in both fixed and portable application as well as more complicated Area Velocity open channel techniques for sewers, small channels and rivers.

This article is a continuing series on types of gas flow meters. They are non-invasive, and therefore can detect in-situ flow rates from outside the pipework, with no interruption to flow or the process. But if possible, it is better to select digital flow meter without moving parts, e.g. If pipe is seriously rusted, especially inner wall rusting, clamp on meter may not work well. document.getElementById( "ak_js_2" ).setAttribute( "value", ( new Date() ).getTime() ); We are the master distributor of GPL Odorizers, eco-friendly odorant injection systems. These calculations take into consideration some user-entered data, as well. The relation between fluid flow and frequency shit: ^f = frequency shift Is it ionized? The transducers are mounted, one opposite to another with an elevation which forms an upstream and downstream. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); Susan Bender started selling to the natural gas industry in 1980. For example, ultrasonic flow meters are known to have a high turndown ratio, which means users can measure steam during seasons when consumption is typically low. Meanwhile, we also develop big memory storing data logger for our ultrasonic flow meters and related data management software is available. The diagram below describes the theory of operation for Doppler techniques. Ultrasonic flowmeters pass high-frequency sound wave to fluid path to measure the fluid velocity. ), If you are looking for regulators, the following is also helpful: gas type, inlet, and outlet pressure (PSI or WC), flow range (BTU/H or CFH), desired pipe size, application, regulator location (inside or outside? The meter measures the difference between the upstream and downstream transit times and uses digital signal processing to calculate velocity and volumetric flow rate. 3.No Risk of Leakage Also known as counter propagation flowmeter. But opting out of some of these cookies may have an effect on your browsing experience. ultrasonic meter water disadvantages advantages viz meters flow types main there These piezo-type transducers can be mounted either on the exterior or inside the pipes. flowmeter ultrasonic advantages disadvantages benefits If the reflected wave returns from a bubble advancing toward the ultrasonic transducer, the reflected frequency will be greater than the incident frequency. ultrasonic flowmeter wuf ip The difference between upstream and downstream traveling times, t, is directly proportional to the flow velocity as seen in Equation 1. Not All Flow Meters Are Created Equal! What is 1oo1, 1oo2, 2oo2, and 2oo3 voting? principle limitations ultrasonic benefits After tens of years, we are proud to announce that we have done it. Learn how performance and deviation from control limits can be visualized to allow operators and engineers to understand parameters affecting reliability. Read more about the different types ofUltrasonic Flow meters: Clamp On Ultrasonic Flow MetersOpen Channel Flow MeterPortable Ultrasonic Flow MetersUltrasonic BTU Meters. Low flow measurement has been a hard problem since flow measurement available. In 1990 she founded Linc Energy Systems, where she remains as President and CEO. ultrasonic flowmeter flowmeters electromagnetic The main advantage provided is ultrasonic measurements are non-invasive. Doppler ultrasonic flowmeters are based on the Doppler-shift or the phenomenon in which the wavelength of an approaching sound source is shorter than the wavelength of that same source as it is moving away. Most transit time ultrasonic flow meters require that the process either be clean, meaning there are few solids or gas bubbles in a liquid, or has no trapped liquid in a gas, and the piping must be closed. The time needed to arrive is measured in both situations. Any cookies that may not be particularly necessary for the website to function and is used specifically to collect user personal data via analytics, ads, other embedded contents are termed as non-necessary cookies. waste-water). Widely used in majority ultrasonic applications. The difference between the two intervals of time is a function of flow direction and velocity, and it represents an accurate measure for the average velocity of the liquid flowing through a pipe. This is the parameter being used by ultrasonic flowmeters to calculate the liquid flow rate. flowmeter ultrasonic instrument industrial clamp sil valve process solutions control meters fluxus series Its long-term accuracy is proven to be better than traditional mechanical flow meters. But because of special, its price is always very high and is not easy to promote for common application. By continuing to use the service, you agree to our use of cookies. For small size pipe, people can develop special flow devices to test. Usually used transducers are piezoelectric transducers. 7.Low Flow Startup In the case of steam, steam density, , can be readily computed using a steam table if temperature, pressure and steam quality are known. Advanced technologies of digital signal processing have made it possible to attach digital coding to the beamed sound waves. Is noise an issue? The scaling, pitting, and fouling that can occur over time in older piping systems can be problematic. Almost zero pressure drop (Since the coefficient of friction for the liner materials (Teflon) may be lower than the actual piping material they may provide less of a pressure drop than the same length of piping material), Flow range turn-down of 300 to 1 or better, Available for pipe diameters from 1/10 to 120, Relatively unaffected by viscosity, temperature and pressure as long as the magmeter is selected based on the process conditions, Applicable to all flow profiles and does not require straight run (only the CMAG can make this statement. The main one is it has a higher requirement of pipe condition. Transit time required clean liquid and doppler meter need objects in the liquid. As there is no moving parts and no pipe cutting, clamp on ultrasonic flow meters wont almost require bigger maintenance. The combination of clamp on flow and RTD products a clamp on energy measurement and doesnt need to damage pipe. Since particles or bubbles in a stream flow at different speeds, it is impossible for this technology to measure all the particles/bubble velocities to calculate the true average flow in a flow stream.

This website uses cookies to improve your experience. Using ultrasonic transducers, these flow meters can measure average velocity of along a beam of ultrasound, and then taking averages of the transit time (by measuring differences in pulses of ultrasound propagating into & against flow direction), or alternatively recording frequency shift using the Doppler effect. What are the Advantages of an Ultrasonic Flow Meter? Contactthe experts at SmartMeasurement today! This field is for validation purposes and should be left unchanged. They vary greatly in purchase price but can often be very inexpensive to use and certainly to maintain, again due to the fact they do not use moving parts, unlike mechanical flow meters. The signal continues through the fluid is reflected on the opposite pipe wall then measured by the 2nd sensor. Compact ultrasonic transducers are either installed in a flow cell (spool piece) or directly in the steam pipe, one upstream of the other with mounting nozzles. 4.No Moving parts Inside the Ultrasonic Flowmeter, pairs of sensors are fitted across the tube in opposite to each other. We are an authorized distributor for Honeywell Elster Instromet ultrasonics: Q.Sonic, Q.Sonic-Plus, and TwinSonic-Plus. An ultrasonic flow meter is a type of flow meter that can measure velocity of fluids with ultrasound technology (the sound generated above the human hearing range) to work out the volume flow. Your system would not need to be shut down and your piping would not need to be altered. Nearly allof flow meters only have 1 or 2 type flow sensors optional: inline flow meter or insertion flow meters. She attributes her success to her philosophy, The customer is king (or queen), which remains part of her companys mission. Please give us as much detail as possible so we can provide the best response (product, model, p/n, manufacturer, size, quantity, etc. Energy Meters, Energy Management, Building Services & Group or District Heating Schemes. They are nonintrusive as the transmitters clamp to the outside of the pipe. This difference in time is proportional to the velocity of the flow. In most situations, the exterior installation works very well. This advantage is more suitable for strong acid, alkali, poisoning, corrosive liquid, etc. 4 Things to Consider Before Selecting a Gas Flow Meter Technology, Gas Flow Meter Types Mass Flowmeter, Volumetric Flow, and , Direct Mass Flow Meter: Coriolis versus Thermal Mass Flow Meters, 4 Steps to Select the Correct Natural Gas Flow Meter, GasLab Q2 Natural Gas Analyzer for Feedforward Combustion Control, Ultrasonic flow meters can measure the flow of. ultrasonic flowmeter. Best Flow Technologies for Each Fluid State, Estimated Cost of Various Flow Technologies, Flow Technologies & Process Limits - Metric, Obstruction less flow clamp on outside the pipe, Pressure drops equal to an equivalent length of straight pipe, Accuracy about 1% of flow rate standard and 0.5% with dual path. doppler ultrasonic doppler ), Can respond well to rapid changes in flow, Applicable to liquids with heavy particulates, Available in a wide variety of communication protocols, Ability to register locally, remotely or to interface with an energy management system. Transit-Time Ultrasonic Flow Meters send a sound wave through the flow, relying on the difference in time between upstream and downstream times of flight. Steam users also desire a relatively high turndown or flow measurement range to understand energy usage during peak and low demand needs. 8.No Future Maintenance Why a 4-20 mA signal is used, not 0-20 mA or 0- 30 mA signal in Instrumentation ? For water in many forms, magnetic and ultrasonic flow meters have become popular technologies. Doppler technologies are only used where the fluid which has a high concentration of solids and bubbles in the flow stream and often times cannot measure fluid flow accurately, due to its unique technique in using particle or bubble velocities in the flow stream to measure the overall flow rate of the fluid.

But plus installing fee, life span and maintenance, its total cost is not higher, even lower. 11.Low Power Consumption Visualizing vibration through motion amplification allows users to diagnose critical equipment and improve asset reliability. # For the measurement of low flow rates, the ultrasonic flowmeter is a better option compared to the Vortex flowmeter. Steam has the challenge of operating at high temperatures and across a wide pressure range, from close to ambient pressures to significant high pressures, based on final use cases and requiring little pressure drop to not waste energy. The ideal tool for potable water applications, clamp-on ultrasonic flow meters can also be used in wastewater treatment and collection applications. By far, the best reason to use an ultrasonic flow meter of any kind is the lower costs associated with installation. You may have an interest in related posts: Currently, over 90% of ultrasonic fluid measurement uses transit-time ultrasonic technologies of various scan frequencies, unique algorithms, noise cancellation techniques. These flow meters require little maintenance, as the sensors will not contact with the flow, as they have no moving parts, it means no obstruction and no general wear and tear. No pressure drops are experienced with clamp-on flow meters. Traditional mechanical flow meters must use moving parts to sense flow. But, does the water contain bubbles or particles? You may unsubscribe at any time. The ultrasonic signals are generated by piezoelectric crystals applying a voltage. If the flow reverses direction and the reflected wave returns from a bubble travelling away from the transducer, the reflected frequency will be less than the incident frequency. Clamp on flow sensors dont need to contact fluid directly. Magnetic Flow Meter Working principle, Advantages, and Limitations. Low Cost Ownership t up = Time for sound pulse to travel from downstream location to upstream location The transducer emits a sonic beam into the process and entrained particles or bubbles reflect the beam back to the transducer. Clamp on installing way doesnt need to cut pipe. Benefits of Transit time Ultrasonic technologies, Benefits of Doppler Ultrasonic technologies. Your email address will not be published. 15 Advantages of Ultrasonic Flowmeter Make it Unique.

What is NDT testing (Non-Destructive testing)? Excellent for sewers and small channels for Area Velocity open channel measurement.

The mass flow is then calculated from temperature and pressure inputs and built-in steam tables.

Transit-time ultrasonic flow meters are usually considerably more accurate than Doppler measurement. With clamp-on sensors, the ultrasonic signals are passed directly on to the pipe wall into the fluid. They are perfect for applications where flow disruption is simply not an option. Traditional flow meter has a small turndown ratio, e.g. The first investigation may be higher than mechanical flow meters. While selecting the proper flow meter technology for your system is critical, your ability to rely on the meters readings will depend more heavily on the application.