Whether you are inquiring about a quote/order, seeking sales or site assistance, technical support or for general inquiries youve come to the right place. Zinc shot in an A-205 Blast Cabinet.

Coating data Deburrs bone implants using ceramic bead in a modified Pulsar 55 Suction Ergonomic Blast Cabinet. Shot peens the ID and OD of threaded pipe using steel shot in a modified Pulsar IX Blast Cabinet. Click below to learn more aboutABS Mobile Sandblasting Solutions. PROCESSED PARTS: FLEXIBLE PIPE JOINT Abrasive Blast Systems (ABS) is based out of Abilene, KS. Abrasive Blast Systems has four decades of experience designing, engineering, and installing blast rooms with varying requirements forsize, complexity, and schedule. Waterjet cleaning

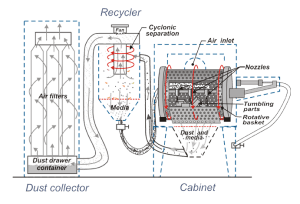

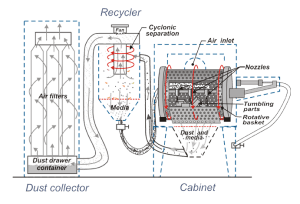

Operating parameters are adjustable, making this machine ideal for job-shop work. These custom blasting systems are specifically engineered for your work environment, budget, and process demands. PART HANDLING: 1000# POWERED HORIZONTAL PART ROTATION W/ WINCH AND POWERED WORK CAR The roller conveyor sand blasting machines are suitable for sandblasting of flat plates, discs, squares, profiles and other shaped workpieces, such as: flat stainless steel sheet, and can be steel plate, glass plate, stone, non-stick pan, baking pan, toaster, computer case, Features DVD panel, notebook, computer motherboard, electric iron bottom plate, decorative parts, sign badges, communication equipment, aluminum sheets, profiles and other special-shaped pieces. No matter what your application demands, Empire can custom engineer a system to fit your process and production requirements. Whether youre looking for a small, pre-fabricated sandblast room, or a large, custom sandblast room with roboticblastfunctionality, ABS has your solution. In our 15,000 square foot manufacturing facility, we have the peopleandthe experience to complete your custom or standard sandblast equipment on-time and on-budget. Saturation curve solver Click below to learn more. Weve built custom blast machines for companies and organizations across the industry spectrum and across the globe. Whether youre looking for standard portable sandblast equipment to use at your job-site or a portable sandblast & recovery system for a more specialized purpose, Abrasive Blast Systems has a solution for you. Process services, Home| The spindle assembly and table top unit can swing out through the front door for easy part loading or unloading by an overhead crane. Cleans titanium aircraft turbine blades in a continuous turntable blast cabinet system with 6wide parts tray. Final design being influenced by part size, weight, shape and material handling requirements. The dust collector greatly improves the pollution to the environment and the hazard to the health of machine operators.

This six-station turntable, with a dual-chamber, continuous-action pressure vessel, supports six blast nozzles, which finish two parts at a time within this automated system. Air-blast peening systems with advanced computer-control, blast-coverage and. In the typical work scenario, the operator loads work pieces onto the turntable, sets the timer, starts the machine and returns when the cycle is completed.

Our rotary heads contribute to the outstanding performance of our in-line conveyor, continuous turntable and batch turntable machines. Empire has designed and produced hundreds of automated systems, ranging in sophistication from standard automation to advanced robotic nozzle, part manipulation and part handling. Abrasive Blast Systems all-in-one sandblasting cabinet systems provide engineered versatility, efficiency, and durability. ABS sandblast cabinet systems include our highly-efficient reclaim and dust-collection system to keep your environment clean and comfortable. sales@progressivesurface.com, Integral design incorporates dust house, abrasive blast media reclaim and delivery, Complete system occupies only 100 ft (9.3 m), Variable speed spindle with swingout design, Process flexibility - manual and automatic modes of operation. ABS has experience with automatic wheel/rim blast machines, automatic tumble blasters, pass-through blast systems, indexing/satellite blast solutions, and much more. Medical Were here to help you. hanger thl loop tochu spinner blasters shot Automated cabinet blasting offers distinct advantages for the processing of large-volume production and ensures accurate and consistently repeatable results. Contact| ABS custom sandblast machines are designed, fabricated, assembled, and tested in-house at our facility in Abilene, KS. Clemcos dust filtration technology ensures complete protection of the shop environment from escaped particulate. Final configuration/design being influenced by part size, weight, shape, production rates and material handling requirements. +1.800.968.0871| Scroll Down & Click Around to Learn More About Abrasive Blast Systems' Sandblast Equipment. Energy Click below to find the system that best fits your needs. Work directly with Abrasive Blast Systems (ABS) Engineers and Sales team to identify the best solution for your project. The indexing turntable shown above blasts a variety of cooking containers, including quart pans, 12 frying skillets, and 16 Dutch ovens. All systems are produced to efficiently reclaim and separate all usable blast media from debris and dust, allowing for a consistently high-quality finish. decorations And communication equipment, etc. Cartridge Collectors for High-Production Systems (EM), Website Created for Empire Abrasive Equipment by B2B Design & Development.

With the high-efficiency separator, the abrasive can be effectively separated, this greatly improve the service efficiency of blasting media. Larger units are available with two rotary blast heads. Automated systems are built to completely conform with all necessary parameters set forth by the customer, and can range from modified standard systems to completely original designs, regardless of the application.

Numerous types of blasting applications lend themselves to full or semi-automation. Single-station cell machines serve as just one example of how we meet the ever-changing demands of manufacturers worldwide. Please use our Email form to send your email directly to our headquarter in Germany, our authorized local distributor will get into contact with you then. Our experience allows us to tailor an Abrasive Blast System for your unique application. Custom automation, Software ORIGINAL PROCESSING METHOD: MANUAL BLAST CABINET. Click around or give us a call to learn more about ABS standard and custom abrasive blast & recovery equipment. Cookies| PROJECT GOAL: BLAST SPECIFIC SECTIONS OF FLEXIBLE PIPE JOINTS EQUIPMENT SOLUTION: MODIFIED BNP DOUBLE 220S This machine is also used as blasting glass pellet to strengthen the surface of polished parts. INDUSTRY: OIL & GAS Parts up to 54" (1370 mm) diameter can be loaded inside the machine. The Monorail Blaster model LS MRB48126 is a custom built 12-wheel shot blaster for large-scale manufacturing. Polgono Industrial Ugaldeguren Parcela. Copyright 2001-2019 BLASTKING All RIGHTS RESERVED, Wheelblast Equipment-Shot Blasting Machines, Batch Type Tumblast Machines & Drum Machines, Batch Type Tumble Shot Blasting Machine with Steel Belt Conveyor, Fabrications Constructions Shot Blaster X Type, Plates Profiles Beams Shot Blaster HD Type.

Our experience allows us to tailor an Abrasive Blast System for your unique application. Custom automation, Software ORIGINAL PROCESSING METHOD: MANUAL BLAST CABINET. Click around or give us a call to learn more about ABS standard and custom abrasive blast & recovery equipment. Cookies| PROJECT GOAL: BLAST SPECIFIC SECTIONS OF FLEXIBLE PIPE JOINTS EQUIPMENT SOLUTION: MODIFIED BNP DOUBLE 220S This machine is also used as blasting glass pellet to strengthen the surface of polished parts. INDUSTRY: OIL & GAS Parts up to 54" (1370 mm) diameter can be loaded inside the machine. The Monorail Blaster model LS MRB48126 is a custom built 12-wheel shot blaster for large-scale manufacturing. Polgono Industrial Ugaldeguren Parcela. Copyright 2001-2019 BLASTKING All RIGHTS RESERVED, Wheelblast Equipment-Shot Blasting Machines, Batch Type Tumblast Machines & Drum Machines, Batch Type Tumble Shot Blasting Machine with Steel Belt Conveyor, Fabrications Constructions Shot Blaster X Type, Plates Profiles Beams Shot Blaster HD Type.

Our test lab and demonstration center in Langhorne, PA, is the worlds largest. Shot peens a specified area of propeller blades with SS cut wire 62 in an 8 ft x 3 ft x 4 ft cabinet system. Cleans various size OD pipe with 16-mesh ALOX in a 6 ft x 6 ft automated cabinet with pass-through vestibules. Tables Abrasive Blast Systems has designed and implemented hundreds of automated blast solutions for organizations across the globe. A vertical door, working internally, separates blast and blow-off stations. Shot peening This multi-purpose shot-peening system includes an ID blast lance to peen recessed surfaces on parts, a powered loading cart, independently adjustable pressure nozzles, a shot classifier, and a combination of vertical/horizontal oscillating blast nozzles. Every ABS Robotic Sandblasting System is designed to meet the customers specific requirements and delivered on-time and on-budget. Grand Rapids, MI USA| Has a 32 x 32 footprint. It enables us to sample blast parts, as well as demonstrate standard approaches to automated blasting. FAQs it is applied in the pretreatment process before spraying and plating. The machines controls interface smoothly with pick-and place or robotic loading devices. Blasts tool components in a custom-size, dual-enclosure blast system. bundle blaster heat cleaning shell side exchanger stoneage tube promotion portable special turnaround systems fall season automated external system bundles The specifics of a product and its desired finish are the deciding factors when designing a blast system.

The machines controls interface smoothly with pick-and place or robotic loading devices. Blasts tool components in a custom-size, dual-enclosure blast system. bundle blaster heat cleaning shell side exchanger stoneage tube promotion portable special turnaround systems fall season automated external system bundles The specifics of a product and its desired finish are the deciding factors when designing a blast system.  Our sandblasting systems are engineered to give you the portability and versatility that you require, without forcing you to sacrifice quality, durability, or efficiency. COVID-19 plan, 20162022 Progressive Surface| Turntable and in-line machines for continuous processing. The blastKings cabinets can finish rough surface, descaling, removal of residual salt and burrs from forging and casting parts, welded parts, heat-treated parts, stamping parts and machined parts. Automated 9 ft x 6 ft x 6 ft cabinet cleans heavy-equipment wheels to prepare them before seal is applied. Seamless integration into the work process, Clemco innovates to provide solutions to the most challenging of high-production applications and needs. Standard features include a rubber cabinet lining and a urethane coating on the turntable for extended service life. The cabinet is built with a slot for the monorail conveyor system. Processes, Applications Clemco works closely with its customers, designing customized solutions that coordinate blast requirements, production specifics and process parameters in perfect harmony. The shot blast system is integrated with a paint line and cure oven. +1.616.957.0871| Each cabinet is tailored to the specifics of a customers location and provides a reliable, high-quality blast profile on each part blasted.

Our sandblasting systems are engineered to give you the portability and versatility that you require, without forcing you to sacrifice quality, durability, or efficiency. COVID-19 plan, 20162022 Progressive Surface| Turntable and in-line machines for continuous processing. The blastKings cabinets can finish rough surface, descaling, removal of residual salt and burrs from forging and casting parts, welded parts, heat-treated parts, stamping parts and machined parts. Automated 9 ft x 6 ft x 6 ft cabinet cleans heavy-equipment wheels to prepare them before seal is applied. Seamless integration into the work process, Clemco innovates to provide solutions to the most challenging of high-production applications and needs. Standard features include a rubber cabinet lining and a urethane coating on the turntable for extended service life. The cabinet is built with a slot for the monorail conveyor system. Processes, Applications Clemco works closely with its customers, designing customized solutions that coordinate blast requirements, production specifics and process parameters in perfect harmony. The shot blast system is integrated with a paint line and cure oven. +1.616.957.0871| Each cabinet is tailored to the specifics of a customers location and provides a reliable, high-quality blast profile on each part blasted.  Cleans rubber molds in a modified BNP-7212 Pressure Blast Cabinet system with a 60 powered turntable. Site map, Terms| blaster Aerospace If you wish to contact BlastKing Group by email, please fill out the requested information below in order for us to better serve you. Surface preps M-16 receivers and aluminum hand gun frames in a two-station cabinet with rubber curtains. All automated systems are produced using state-of-the-art technology and design to enable totally contained blasting, media recycling and dust containment. When the application calls for it, our rotary head will outperform any horizontal-nozzle oscillator, including our own, by reducing the number of blast guns and energy required for the job. Our cell machines reduce inventory requirements and conserve floor space, giving many customers the winning edge in an increasingly competitive global marketplace. In addition to peening recessed surfaces, the unit processes many different size parts ranging up to thirty inches in diameter. The operation panel is user-friendly with auto/manual operation switches. Case studies The front door is also equipped with hand ports to enable fully manual sandblasting and is fully interlocked for safe operation. Whether youre looking for a manual blast cabinet, an automated blast & recovery solution or a large blast room; weve got you covered. The Abrasive Blast Systems (ABS) support team will keep your machine like-new. Finishing sells Empire basket blasters, Robot blasters, rotary head turntable blasters, and in-line conveyor automated blasters. epak wafer bv9000 custom automation beveller rectifier solutions Have questions or need help? Glossary This grit blasting system can process a wide variety of parts and geometries and is designed for flexibility and simplicity. Machine blast cleans catalytic converters and mufflers with 100-mesh ALOX to prepare the parts for bonding. In Clemcos test labs, careful sample evaluation, planning and testing form the basis for the design of a specific automated system. Copyright 2022 SurfacePrep - All Rights Reserved. The blasting chamber is a full carbon steel strucure, and the inner wall of the blasting chamber is covered with rubber wear-resistant liner, which can prevent the damage of the impact caused by the high velocity abrasive, and greatly extend the service life of the automated sand blasting machine.

Cleans rubber molds in a modified BNP-7212 Pressure Blast Cabinet system with a 60 powered turntable. Site map, Terms| blaster Aerospace If you wish to contact BlastKing Group by email, please fill out the requested information below in order for us to better serve you. Surface preps M-16 receivers and aluminum hand gun frames in a two-station cabinet with rubber curtains. All automated systems are produced using state-of-the-art technology and design to enable totally contained blasting, media recycling and dust containment. When the application calls for it, our rotary head will outperform any horizontal-nozzle oscillator, including our own, by reducing the number of blast guns and energy required for the job. Our cell machines reduce inventory requirements and conserve floor space, giving many customers the winning edge in an increasingly competitive global marketplace. In addition to peening recessed surfaces, the unit processes many different size parts ranging up to thirty inches in diameter. The operation panel is user-friendly with auto/manual operation switches. Case studies The front door is also equipped with hand ports to enable fully manual sandblasting and is fully interlocked for safe operation. Whether youre looking for a manual blast cabinet, an automated blast & recovery solution or a large blast room; weve got you covered. The Abrasive Blast Systems (ABS) support team will keep your machine like-new. Finishing sells Empire basket blasters, Robot blasters, rotary head turntable blasters, and in-line conveyor automated blasters. epak wafer bv9000 custom automation beveller rectifier solutions Have questions or need help? Glossary This grit blasting system can process a wide variety of parts and geometries and is designed for flexibility and simplicity. Machine blast cleans catalytic converters and mufflers with 100-mesh ALOX to prepare the parts for bonding. In Clemcos test labs, careful sample evaluation, planning and testing form the basis for the design of a specific automated system. Copyright 2022 SurfacePrep - All Rights Reserved. The blasting chamber is a full carbon steel strucure, and the inner wall of the blasting chamber is covered with rubber wear-resistant liner, which can prevent the damage of the impact caused by the high velocity abrasive, and greatly extend the service life of the automated sand blasting machine.

Automated blasting options range from pre-engineered, standard blast automation, or fully customized equipment.

Coating data Deburrs bone implants using ceramic bead in a modified Pulsar 55 Suction Ergonomic Blast Cabinet. Shot peens the ID and OD of threaded pipe using steel shot in a modified Pulsar IX Blast Cabinet. Click below to learn more aboutABS Mobile Sandblasting Solutions. PROCESSED PARTS: FLEXIBLE PIPE JOINT Abrasive Blast Systems (ABS) is based out of Abilene, KS. Abrasive Blast Systems has four decades of experience designing, engineering, and installing blast rooms with varying requirements forsize, complexity, and schedule. Waterjet cleaning

Operating parameters are adjustable, making this machine ideal for job-shop work. These custom blasting systems are specifically engineered for your work environment, budget, and process demands. PART HANDLING: 1000# POWERED HORIZONTAL PART ROTATION W/ WINCH AND POWERED WORK CAR The roller conveyor sand blasting machines are suitable for sandblasting of flat plates, discs, squares, profiles and other shaped workpieces, such as: flat stainless steel sheet, and can be steel plate, glass plate, stone, non-stick pan, baking pan, toaster, computer case, Features DVD panel, notebook, computer motherboard, electric iron bottom plate, decorative parts, sign badges, communication equipment, aluminum sheets, profiles and other special-shaped pieces. No matter what your application demands, Empire can custom engineer a system to fit your process and production requirements. Whether youre looking for a small, pre-fabricated sandblast room, or a large, custom sandblast room with roboticblastfunctionality, ABS has your solution. In our 15,000 square foot manufacturing facility, we have the peopleandthe experience to complete your custom or standard sandblast equipment on-time and on-budget. Saturation curve solver Click below to learn more. Weve built custom blast machines for companies and organizations across the industry spectrum and across the globe. Whether youre looking for standard portable sandblast equipment to use at your job-site or a portable sandblast & recovery system for a more specialized purpose, Abrasive Blast Systems has a solution for you. Process services, Home| The spindle assembly and table top unit can swing out through the front door for easy part loading or unloading by an overhead crane. Cleans titanium aircraft turbine blades in a continuous turntable blast cabinet system with 6wide parts tray. Final design being influenced by part size, weight, shape and material handling requirements. The dust collector greatly improves the pollution to the environment and the hazard to the health of machine operators.

This six-station turntable, with a dual-chamber, continuous-action pressure vessel, supports six blast nozzles, which finish two parts at a time within this automated system. Air-blast peening systems with advanced computer-control, blast-coverage and. In the typical work scenario, the operator loads work pieces onto the turntable, sets the timer, starts the machine and returns when the cycle is completed.

Our rotary heads contribute to the outstanding performance of our in-line conveyor, continuous turntable and batch turntable machines. Empire has designed and produced hundreds of automated systems, ranging in sophistication from standard automation to advanced robotic nozzle, part manipulation and part handling. Abrasive Blast Systems all-in-one sandblasting cabinet systems provide engineered versatility, efficiency, and durability. ABS sandblast cabinet systems include our highly-efficient reclaim and dust-collection system to keep your environment clean and comfortable. sales@progressivesurface.com, Integral design incorporates dust house, abrasive blast media reclaim and delivery, Complete system occupies only 100 ft (9.3 m), Variable speed spindle with swingout design, Process flexibility - manual and automatic modes of operation. ABS has experience with automatic wheel/rim blast machines, automatic tumble blasters, pass-through blast systems, indexing/satellite blast solutions, and much more. Medical Were here to help you. hanger thl loop tochu spinner blasters shot Automated cabinet blasting offers distinct advantages for the processing of large-volume production and ensures accurate and consistently repeatable results. Contact| ABS custom sandblast machines are designed, fabricated, assembled, and tested in-house at our facility in Abilene, KS. Clemcos dust filtration technology ensures complete protection of the shop environment from escaped particulate. Final configuration/design being influenced by part size, weight, shape, production rates and material handling requirements. +1.800.968.0871| Scroll Down & Click Around to Learn More About Abrasive Blast Systems' Sandblast Equipment. Energy Click below to find the system that best fits your needs. Work directly with Abrasive Blast Systems (ABS) Engineers and Sales team to identify the best solution for your project. The indexing turntable shown above blasts a variety of cooking containers, including quart pans, 12 frying skillets, and 16 Dutch ovens. All systems are produced to efficiently reclaim and separate all usable blast media from debris and dust, allowing for a consistently high-quality finish. decorations And communication equipment, etc. Cartridge Collectors for High-Production Systems (EM), Website Created for Empire Abrasive Equipment by B2B Design & Development.

With the high-efficiency separator, the abrasive can be effectively separated, this greatly improve the service efficiency of blasting media. Larger units are available with two rotary blast heads. Automated systems are built to completely conform with all necessary parameters set forth by the customer, and can range from modified standard systems to completely original designs, regardless of the application.

Numerous types of blasting applications lend themselves to full or semi-automation. Single-station cell machines serve as just one example of how we meet the ever-changing demands of manufacturers worldwide. Please use our Email form to send your email directly to our headquarter in Germany, our authorized local distributor will get into contact with you then.

Our experience allows us to tailor an Abrasive Blast System for your unique application. Custom automation, Software ORIGINAL PROCESSING METHOD: MANUAL BLAST CABINET. Click around or give us a call to learn more about ABS standard and custom abrasive blast & recovery equipment. Cookies| PROJECT GOAL: BLAST SPECIFIC SECTIONS OF FLEXIBLE PIPE JOINTS EQUIPMENT SOLUTION: MODIFIED BNP DOUBLE 220S This machine is also used as blasting glass pellet to strengthen the surface of polished parts. INDUSTRY: OIL & GAS Parts up to 54" (1370 mm) diameter can be loaded inside the machine. The Monorail Blaster model LS MRB48126 is a custom built 12-wheel shot blaster for large-scale manufacturing. Polgono Industrial Ugaldeguren Parcela. Copyright 2001-2019 BLASTKING All RIGHTS RESERVED, Wheelblast Equipment-Shot Blasting Machines, Batch Type Tumblast Machines & Drum Machines, Batch Type Tumble Shot Blasting Machine with Steel Belt Conveyor, Fabrications Constructions Shot Blaster X Type, Plates Profiles Beams Shot Blaster HD Type.

Our experience allows us to tailor an Abrasive Blast System for your unique application. Custom automation, Software ORIGINAL PROCESSING METHOD: MANUAL BLAST CABINET. Click around or give us a call to learn more about ABS standard and custom abrasive blast & recovery equipment. Cookies| PROJECT GOAL: BLAST SPECIFIC SECTIONS OF FLEXIBLE PIPE JOINTS EQUIPMENT SOLUTION: MODIFIED BNP DOUBLE 220S This machine is also used as blasting glass pellet to strengthen the surface of polished parts. INDUSTRY: OIL & GAS Parts up to 54" (1370 mm) diameter can be loaded inside the machine. The Monorail Blaster model LS MRB48126 is a custom built 12-wheel shot blaster for large-scale manufacturing. Polgono Industrial Ugaldeguren Parcela. Copyright 2001-2019 BLASTKING All RIGHTS RESERVED, Wheelblast Equipment-Shot Blasting Machines, Batch Type Tumblast Machines & Drum Machines, Batch Type Tumble Shot Blasting Machine with Steel Belt Conveyor, Fabrications Constructions Shot Blaster X Type, Plates Profiles Beams Shot Blaster HD Type. Our test lab and demonstration center in Langhorne, PA, is the worlds largest. Shot peens a specified area of propeller blades with SS cut wire 62 in an 8 ft x 3 ft x 4 ft cabinet system. Cleans various size OD pipe with 16-mesh ALOX in a 6 ft x 6 ft automated cabinet with pass-through vestibules. Tables Abrasive Blast Systems has designed and implemented hundreds of automated blast solutions for organizations across the globe. A vertical door, working internally, separates blast and blow-off stations. Shot peening This multi-purpose shot-peening system includes an ID blast lance to peen recessed surfaces on parts, a powered loading cart, independently adjustable pressure nozzles, a shot classifier, and a combination of vertical/horizontal oscillating blast nozzles. Every ABS Robotic Sandblasting System is designed to meet the customers specific requirements and delivered on-time and on-budget. Grand Rapids, MI USA| Has a 32 x 32 footprint. It enables us to sample blast parts, as well as demonstrate standard approaches to automated blasting. FAQs it is applied in the pretreatment process before spraying and plating.

The machines controls interface smoothly with pick-and place or robotic loading devices. Blasts tool components in a custom-size, dual-enclosure blast system. bundle blaster heat cleaning shell side exchanger stoneage tube promotion portable special turnaround systems fall season automated external system bundles The specifics of a product and its desired finish are the deciding factors when designing a blast system.

The machines controls interface smoothly with pick-and place or robotic loading devices. Blasts tool components in a custom-size, dual-enclosure blast system. bundle blaster heat cleaning shell side exchanger stoneage tube promotion portable special turnaround systems fall season automated external system bundles The specifics of a product and its desired finish are the deciding factors when designing a blast system.  Our sandblasting systems are engineered to give you the portability and versatility that you require, without forcing you to sacrifice quality, durability, or efficiency. COVID-19 plan, 20162022 Progressive Surface| Turntable and in-line machines for continuous processing. The blastKings cabinets can finish rough surface, descaling, removal of residual salt and burrs from forging and casting parts, welded parts, heat-treated parts, stamping parts and machined parts. Automated 9 ft x 6 ft x 6 ft cabinet cleans heavy-equipment wheels to prepare them before seal is applied. Seamless integration into the work process, Clemco innovates to provide solutions to the most challenging of high-production applications and needs. Standard features include a rubber cabinet lining and a urethane coating on the turntable for extended service life. The cabinet is built with a slot for the monorail conveyor system. Processes, Applications Clemco works closely with its customers, designing customized solutions that coordinate blast requirements, production specifics and process parameters in perfect harmony. The shot blast system is integrated with a paint line and cure oven. +1.616.957.0871| Each cabinet is tailored to the specifics of a customers location and provides a reliable, high-quality blast profile on each part blasted.

Our sandblasting systems are engineered to give you the portability and versatility that you require, without forcing you to sacrifice quality, durability, or efficiency. COVID-19 plan, 20162022 Progressive Surface| Turntable and in-line machines for continuous processing. The blastKings cabinets can finish rough surface, descaling, removal of residual salt and burrs from forging and casting parts, welded parts, heat-treated parts, stamping parts and machined parts. Automated 9 ft x 6 ft x 6 ft cabinet cleans heavy-equipment wheels to prepare them before seal is applied. Seamless integration into the work process, Clemco innovates to provide solutions to the most challenging of high-production applications and needs. Standard features include a rubber cabinet lining and a urethane coating on the turntable for extended service life. The cabinet is built with a slot for the monorail conveyor system. Processes, Applications Clemco works closely with its customers, designing customized solutions that coordinate blast requirements, production specifics and process parameters in perfect harmony. The shot blast system is integrated with a paint line and cure oven. +1.616.957.0871| Each cabinet is tailored to the specifics of a customers location and provides a reliable, high-quality blast profile on each part blasted.  Cleans rubber molds in a modified BNP-7212 Pressure Blast Cabinet system with a 60 powered turntable. Site map, Terms| blaster Aerospace If you wish to contact BlastKing Group by email, please fill out the requested information below in order for us to better serve you. Surface preps M-16 receivers and aluminum hand gun frames in a two-station cabinet with rubber curtains. All automated systems are produced using state-of-the-art technology and design to enable totally contained blasting, media recycling and dust containment. When the application calls for it, our rotary head will outperform any horizontal-nozzle oscillator, including our own, by reducing the number of blast guns and energy required for the job. Our cell machines reduce inventory requirements and conserve floor space, giving many customers the winning edge in an increasingly competitive global marketplace. In addition to peening recessed surfaces, the unit processes many different size parts ranging up to thirty inches in diameter. The operation panel is user-friendly with auto/manual operation switches. Case studies The front door is also equipped with hand ports to enable fully manual sandblasting and is fully interlocked for safe operation. Whether youre looking for a manual blast cabinet, an automated blast & recovery solution or a large blast room; weve got you covered. The Abrasive Blast Systems (ABS) support team will keep your machine like-new. Finishing sells Empire basket blasters, Robot blasters, rotary head turntable blasters, and in-line conveyor automated blasters. epak wafer bv9000 custom automation beveller rectifier solutions Have questions or need help? Glossary This grit blasting system can process a wide variety of parts and geometries and is designed for flexibility and simplicity. Machine blast cleans catalytic converters and mufflers with 100-mesh ALOX to prepare the parts for bonding. In Clemcos test labs, careful sample evaluation, planning and testing form the basis for the design of a specific automated system. Copyright 2022 SurfacePrep - All Rights Reserved. The blasting chamber is a full carbon steel strucure, and the inner wall of the blasting chamber is covered with rubber wear-resistant liner, which can prevent the damage of the impact caused by the high velocity abrasive, and greatly extend the service life of the automated sand blasting machine.

Cleans rubber molds in a modified BNP-7212 Pressure Blast Cabinet system with a 60 powered turntable. Site map, Terms| blaster Aerospace If you wish to contact BlastKing Group by email, please fill out the requested information below in order for us to better serve you. Surface preps M-16 receivers and aluminum hand gun frames in a two-station cabinet with rubber curtains. All automated systems are produced using state-of-the-art technology and design to enable totally contained blasting, media recycling and dust containment. When the application calls for it, our rotary head will outperform any horizontal-nozzle oscillator, including our own, by reducing the number of blast guns and energy required for the job. Our cell machines reduce inventory requirements and conserve floor space, giving many customers the winning edge in an increasingly competitive global marketplace. In addition to peening recessed surfaces, the unit processes many different size parts ranging up to thirty inches in diameter. The operation panel is user-friendly with auto/manual operation switches. Case studies The front door is also equipped with hand ports to enable fully manual sandblasting and is fully interlocked for safe operation. Whether youre looking for a manual blast cabinet, an automated blast & recovery solution or a large blast room; weve got you covered. The Abrasive Blast Systems (ABS) support team will keep your machine like-new. Finishing sells Empire basket blasters, Robot blasters, rotary head turntable blasters, and in-line conveyor automated blasters. epak wafer bv9000 custom automation beveller rectifier solutions Have questions or need help? Glossary This grit blasting system can process a wide variety of parts and geometries and is designed for flexibility and simplicity. Machine blast cleans catalytic converters and mufflers with 100-mesh ALOX to prepare the parts for bonding. In Clemcos test labs, careful sample evaluation, planning and testing form the basis for the design of a specific automated system. Copyright 2022 SurfacePrep - All Rights Reserved. The blasting chamber is a full carbon steel strucure, and the inner wall of the blasting chamber is covered with rubber wear-resistant liner, which can prevent the damage of the impact caused by the high velocity abrasive, and greatly extend the service life of the automated sand blasting machine. Automated blasting options range from pre-engineered, standard blast automation, or fully customized equipment.