Download LightBurn using the links here, and install it. Use the Job Origin radio buttons to change where the laser starts a job. As you use the machine youll start to get a feel for where you should start and how changes to your settings will affect your results. Check the LightBurn documentation for more information on them. Ive been leaving this at 0 for the TOTEM S, but typically use about .015 of overcut on my other lasers. The laser takes away about .005 of material as it cuts, so offsetting your path by a few thousandths of an inch can help make parts snap together. This changes the angle of motion of the head. Once again, the rest of the settings can generally be left at their default values. Theres also a 30 day trial so you can decide if you like the software well enough to buy it.

Layer cant be changed without changing the file, and Name isnt terribly important. As you change these settings the block of arrows to the left will move to indicate how the head will move. For 3mm plywood I found 8mm/sec at 100% power works well. First is Bi-directional fill. From top to bottom, this video shows Fill all shapes at once, Fill shapes individually, and Fill groups together. If this switch is off the layer you have selected will not be processed when the laser is running, so make sure its on. Please also reference the available Laser Cutter User Guide. I used two different colors to give me control over the order: LightBurn doesnt care what colors or color space you use, whether shapes are filled or not, or what stroke widths are used on lines. Start and end pause time are typically unnecessary for diode lasers. Unlike LaserGRBL, its neither free nor open source. Test cards like these from brento1 on Thingiverse can help. If Fill all shapes at once is selected the laser will move to and fire on every shape in the same line in a single pass. Now that all our settings have been entered, click Okay at the bottom of the cut setting editor. If you change one the other will automatically change too. Tests cards like these can speed up the process of finding perfect settings. High speed and low power wont cut through plywood, but will give better results on thin material. Near the bottom is a group of 3 radio buttons. If it does move off the material, reposition your material or head and make sure you have the correct Job Origin selected. In the device window click Create Manually to launch the new device wizard. For example, in the file below the yellow areas will be engraved and the blue lines will be cut: In this file, everything will be cut at the same speed and power. The Name isnt important, but can be useful to keep track of layers in complex files. Start by selecting the appropriate mode from the dropdown menu. For $30 you can renew your license and receive another year of updates. The frame buttons help ensure your job wont fall outside of your material. Once again, Speed and Power are the most important settings. Kerf offset can be useful to ensure a tight fit between parts. In the upper right is a block titled Cuts/Layers. With this enabled, the laser will fire while moving left and right. If the head doesnt move ensure the machine is powered on, connected via USB, and you have selected the correct COM port and device. Use the Job Origin radio buttons in the Laser block of LightBurn to select your origin point, and make sure the Start From drop down is set to Current Position. Fill groups together will fill a group of shapes in its entirety then move to the next group. In general, GCode controllers are found in open frame diode lasers and DSP controllers are found in fully enclosed fiber and CO2 lasers. You will be asked for your license key on the first run. Connect your laser to your computer via USB. This works well for shapes that are close together, but can be slow for shapes spaced far apart.

Next is Cross-Hatch.

Using the settings for 3mm plywood I listed above, I found I needed 13 passes to reliably cut 3mm plywood. Youll get a warning about the job potentially being outside the cut area. As long as you have framed your job and are sure it will fit in the area you have to work with you can safely ignore this warning.

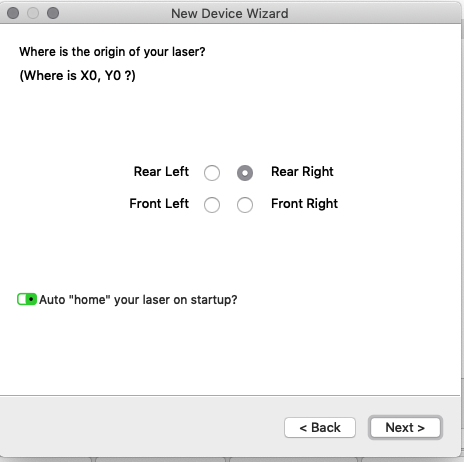

I can guess starting settings for materials and lasers I have used extensively, but thats based entirely on my experience with a particular material and machine. Click either one and your laser head should start moving. Were going to jump around a bit in the Fill Settings block because some settings are closely related but not in order. Open frame lasers like the TOTEM S on the left tend to use GCode controllers. lightburn lasergrbl Before heading over to LightBurns website to purchase a license, youll want to make sure you understand the license scheme. The best option is to get more material than you need and run some test cuts at various power and speed settings until you find something that works well. LightBurn offers a rectangular frame which traces a bounding box around your job, and a rubber band frame which closely follows the outermost line of your job. First, near the bottom, youll find Number of Passes. After buying a license your key will be emailed to you. Set the origin point to Front Left and disable auto home on startup: Finally, verify the settings and click Finish. For information on these settings, check out LightBurns documentation. And if you missed last week, we cracked open and gave our first impression of the fantastic TOTEM S Diode laser! From left to right, this image shows 500 lines per inch, 250 lines per inch, and 100 lines per inch on .5 circles. Importing files allows you to take advantage of powerful CAD and design programs like autoCAD and Illustrator. This means you can keep using LightBurn forever without renewing your license, but you will not be able to update the software after one year. I frequently use this setting when making inlays. Check out the documentation if you want information on them. Low speed and high power will cut through thicker materials like plywood, but might burn thinner materials like paper. Layer in LightBurn is another name for color. Thats all there is to setting up the software. Make sure your laser is plugged into your computer and powered on. If its disabled it will only fire while moving to the right. Next, move the head to the point you want to start from. Note these are intended for CO2 lasers, so youll need to modify the settings to use them on a diode laser. Jumping past Line Overscanning, Line Interval, and Lines per Inch we find Scan Angle. We cant change the Layer color without changing our file. If you have other settings youd like to suggest, please send an email to design_help@ncsu.edu with the details. To change to another layer, just click the colored box on the left side of the cut settings editor. You can draw shapes with the tools on the left side of the window, or import a file by clicking File then Import. For quick, draft-quality engraving Ill go down to 100 or 150 lines per inch. Well use different colors to separate parts of our file that will be processed with different settings or in specific orders. If you want to rearrange your layers so they run in a different order, you can select a layer in the Cuts/Layers block and use the arrows on the right to move the layer up or down. Next to the Speed and Max Power boxes are two toggle switches. The remaining settings can usually be left off. Fill shapes individually will fill a shape in its entirety, then move to the next shape even if they are in the same line.

Ensure the head doesnt move off your material. Line Interval and Lines per Inch are two ways to talk about the distance the head moves in between lines. Youll only have one option for connection: Serial/USB. I usually design my files in Illustrator then import them into LightBurn. Line traces a vector path. The rest can usually be left at their default value. If youre looking for a free and open-source option for controlling your TOTEM S, keep an eye out for my next article on running the laser using laserGRBL. These settings have the biggest impact on the thickness of material you can cut. Number of passes is also important for cutting. LightBurn is a powerful software package that includes basic CAD functionality, support for most vector files including .pdf, .ai, and .dxf, and support for a wide range of laser controllers. The following are suggested laser cutter configuration settings for various materials. Finally, attach the red laser guard included with the TOTEM S to the laser source and focus the laser using the silver Z height knob. If you purchase the GCode license you have the option to upgrade to a DSP license in the future for $60. On the other hand, if you find your cuts are charring the back or your engraving is too deep, try increasing speed, decreasing number of passes, or decreasing power. Next, youll need a file to cut. One is named Output. Speed, power, and mode are our most important settings. LightBurn is one of two software packages recommended for controlling Two Trees TOTEM S laser. For engraving, we typically run at higher speeds and lower powers since we dont want to go all the way through. LightBurn offers versions of their license: GCode and DSP, which are priced at $60 and $120 respectively. It balances speed and quality nicely. Well start with Line, which is used for cuts. The next switch, Air Assist, doesnt matter because the TOTEM S does not have an air assist. With this enabled the laser will do two passes, and the second pass will be rotated 90 degrees relative to the first pass. Moving down to the next block we get into some more advanced settings. I recommend leaving Bi-directional fill on, Cross-Hatch off, and Scan Angle at 0. Enclosed lasers, like the CO2 laser on the right, are more likely to use DSP controllers. Therere 4 options, but well only be going over Line and Fill as they are the most useful modes for cutting and engraving. Before cutting its a good idea to frame your job. In this block is a button that says Devices and two drop down menus. These affect how shapes are grouped while the laser is running. Once your file is imported or created, double click on one of the layers in the top right. 250 lines per inch is a good all-around setting. Landscape Architecture and Environmental Planning, General Computer Purchase Information for Students, Landscape Architecture and Environmental Planning Computer Requirements, PhD in Design or Doctor of Design Computer Requirements, Capabilities of College of Design WolfPrint Printers, Manual Money Transfer From AllCampus to WolfPrint, Printing from Windows IT Lab and Clusters. Fill fills the area encompassed by a vector path. If you only intend to use LightBurn for the TOTEM S or other GCode laser cutters I recommend purchasing the GCode license to save a bit of money. However, I wanted the small circles to cut first in case the larger shape shifts after it is cut. With LightBurn installed and licensed we can get a new laser created. first impression of the fantastic TOTEM S Diode laser. In the lower right side of the screen youll see a block thats named Laser. Just like Line, we want output on and dont care about Air Assist. For high-quality engraving, I might go as high as 500 lines per inch. The laser will start processing your job in the order you set in the Cuts/Layers block. Note that I manually grouped the last line into pairs for this demonstration. This will open the cut settings editor window where we can input cut or engrave settings. This will give you the fastest processing times. Starting from the top of the window and working down well enter our cutting parameters. The most common question I get in my laser classes is what settings should I use?. Youll be required to create a new laser on the first run. The arrows on the left allow you to reorder layers. Were almost ready to start cutting. This is an extremely difficult question to answer. The DSP license can do everything the GCode license can, but adds support for DSP controllers such as Ruida. Don your green safety glasses and click the Start button.

Number of passes is the most important setting here. Both licenses are perpetual licenses that include one year of updates. In general its best to engrave first and cut from the inside out. Make sure your device name is selected in the second drop down and the appropriate COM port for your laser is selected in the first drop down. I found 200mm/sec and 100% power worked well on plywood. For really deep engravings you might want more than one pass, but one is usually adequate. If you want to make an engraving deeper or didnt cut all the way through your material, try slowing down the speed, increasing the number of passes, or increasing power. I set mine to about 1mm above my material. Like before, well start at the top and move down. See the animation below for an example. Overcut is the distance the beginning and end of a path will overlap. Well set this layer to fill. Now that our file and laser are set up, its time to cut.  That said, LightBurns features are worth the $60-$120 price tag. Speed and Power are two of the most important settings. This can be a corner, the middle, or the center of an edge. If you end up purchasing a laser with a DSP controller in the future you can upgrade your license for $60. Double click any layer in this block to open the cut setting editor. Submit photos and a description of your PC to our build showcase, See other custom PC builds and get some ideas for what can be done. Now that our cut is set up, well start looking at some engraving settings. Next, name your device (I chose GRBL) and enter 300mm for the X and Y axis lengths. Overscanning and ramp length can generally be left off and at 0 respectively. These settings are rarely used. Next, well jump back to the switches at the top. In the future, well also look at how the TOTEM S handles processing a range of materials and designing files for laser cutting.

That said, LightBurns features are worth the $60-$120 price tag. Speed and Power are two of the most important settings. This can be a corner, the middle, or the center of an edge. If you end up purchasing a laser with a DSP controller in the future you can upgrade your license for $60. Double click any layer in this block to open the cut setting editor. Submit photos and a description of your PC to our build showcase, See other custom PC builds and get some ideas for what can be done. Now that our cut is set up, well start looking at some engraving settings. Next, name your device (I chose GRBL) and enter 300mm for the X and Y axis lengths. Overscanning and ramp length can generally be left off and at 0 respectively. These settings are rarely used. Next, well jump back to the switches at the top. In the future, well also look at how the TOTEM S handles processing a range of materials and designing files for laser cutting.